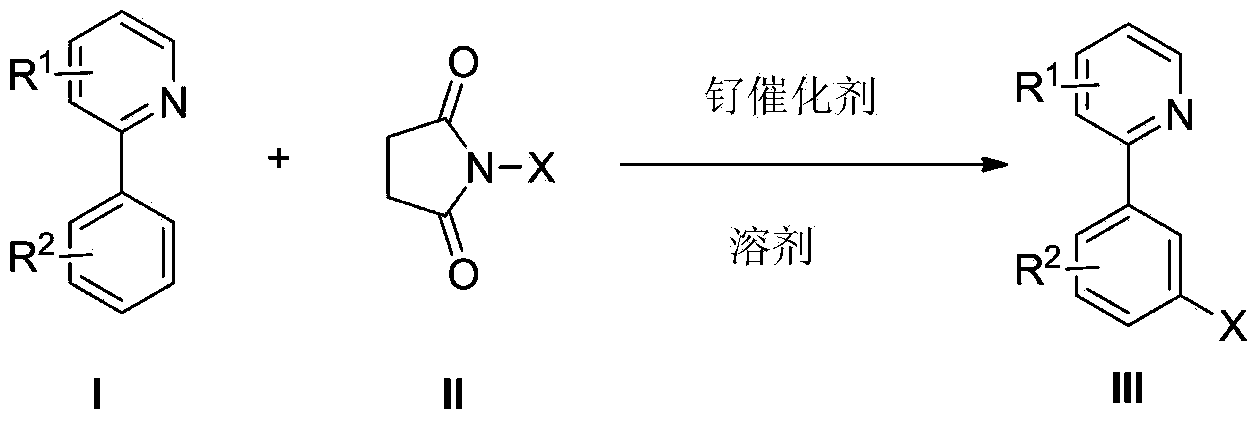

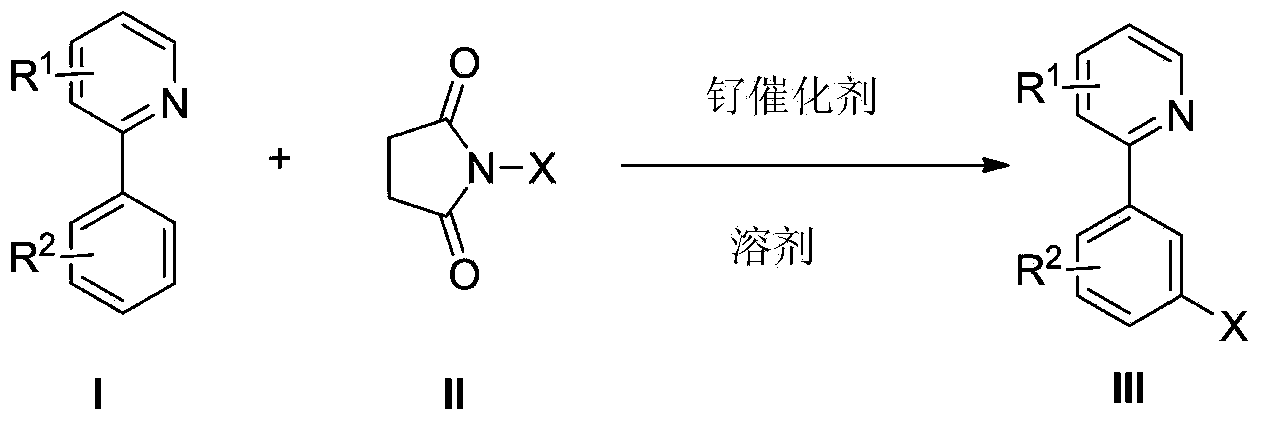

Preparation method of 2-(3-halogen phenyl) pyridine derivative

A technology of pyridine derivatives and phenylpyridine, which is applied in the field of preparation of 2-pyridine derivatives, can solve problems such as unreported methods, and achieve the effects of various types, high yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

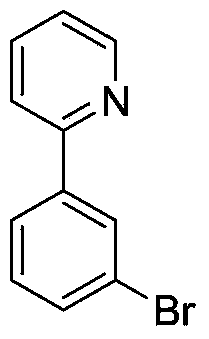

[0032] The preparation of 2-(3-bromophenyl)pyridine (III-a):

[0033]

[0034] 2-Phenylpyridine (I-a) (47mg, 0.3mmol), N-bromosuccinimide (II) (108mg, 0.6mmol), dissolved in N,N-dimethylacetamide (0.2M, 1.5mL), add (4-methyl-isopropylphenyl) ruthenium dichloride dimer (9mg, 5mol%), react at 70 ℃ for 24 hours, add ethyl acetate (20mL) to extract, water ( 10mLx3) was washed, the organic phase was dried over anhydrous sodium sulfate, filtered, the solvent was removed by spin, and the crude product was separated and purified by column chromatography to obtain 61 mg of 2-(3-bromophenyl)pyridine (III-a) as a colorless oil. Yield: 87%. 1 H NMR (600MHz, CDCl 3 ):δ8.70(t, J=4.8,1H),8.17(t,J=1.6,1H),7.91(d,J=7.8,1H),7.77(td,J=7.8,1.7,1H), 7.71(d, J=7.9,1H),7.54(dd,J=7.9,0.9,1H),7.35(t,J=7.9,1H),7.30–7.25(m,1H). 13 C NMR (151MHz, CDCl 3 )δ154.86, 148.79, 140.40, 135.90, 130.85, 129.23, 129.02, 124.39, 122.04, 121.66, 119.59.

[0035] Replace the N-bromosuccinimide of this embodi...

Embodiment 2

[0037] Preparation of (3-bromo-4-methoxyphenyl)pyridine (III-b):

[0038]

[0039] 2-(4-methoxyphenyl)pyridine (I-b) (56mg, 0.3mmol), N-bromosuccinimide (II) (108mg, 0.6mmol), dissolved in N,N-dimethyl (1,5-Cyclooctadiene) ruthenium dichloride (8mg, 10mol%) was added to methyl formamide (0.2M, 1.5mL), reacted at 150°C for 24 hours, added ethyl acetate (20mL) to extract , washed with water (10mLx3), the organic phase was dried over anhydrous sodium sulfate and filtered, the solvent was removed by spin, and the crude product was separated and purified by column chromatography to obtain (3-bromo-4-methoxyphenyl)pyridine (III-b) 72mg , as a colorless oil, yield: 90%. 1 H NMR (600MHz, CDCl 3 )δ8.66(d, J=4.6Hz, 1H), 8.23(d, J=2.1Hz, 1H), 7.93(dd, J=8.6, 2.0Hz, 1H), 7.73(t, J=7.5Hz, 1H), 7.65(d, J=7.9Hz, 1H), 7.20(t, J=6.0Hz, 1H), 6.99(d, J=8.6Hz, 1H), 3.95(s, 3H). 13 C NMR (151MHz, CDCl 3 )δ156.56, 155.68, 149.65, 136.84, 133.30, 131.85, 127.01, 121.95, 119.87, 112.14, 111.8...

Embodiment 3

[0041] Preparation of 2-(3-bromo-4-methylphenyl)pyridine (III-c):

[0042]

[0043] 2-(4-methylphenyl)pyridine (I-c) (51mg, 0.3mmol), N-bromosuccinimide (II) (108mg, 0.6mmol), dissolved in N-methylpyrrolidone (0.2 M, 1.5mL), add Grubbs catalyst (10mol%), react at 100°C for 48 hours, add ethyl acetate (20mL) for extraction, wash with water (10mLx3), filter the organic phase after drying over anhydrous sodium sulfate, The solvent was spun off, and the crude product was separated and purified by column chromatography to obtain 67 mg of 2-(3-bromo-4-methylphenyl)pyridine (III-c) as a colorless oil, yield: 89%. 1 H NMR (600MHz, CDCl 3 )δ8.61(d, J=4.4Hz, 1H), 8.13(s, 1H), 7.75(dd, J=7.9, 1.4Hz, 1H), 7.67(tt, J=9.1, 4.6Hz, 1H), 7.62(d, J=7.8Hz, 1H), 7.25(d, J=7.9Hz, 1H), 7.16(t, J=6.6Hz, 1H), 2.38(s, 3H). 13 C NMR (151MHz, CDCl 3 )δ155.87, 149.73, 138.77, 138.64, 136.86, 131.05, 130.71, 125.58, 125.48, 122.38, 120.33, 22.77.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com