Corrosion resistant brick

A brick and raw material technology, applied in the field of corrosion-resistant bricks, can solve the problems that the performance indicators of ceramic tiles are not suitable for use in certain places, and achieve the effect of expanding the use places, increasing the content of silicon and aluminum, and increasing anticorrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

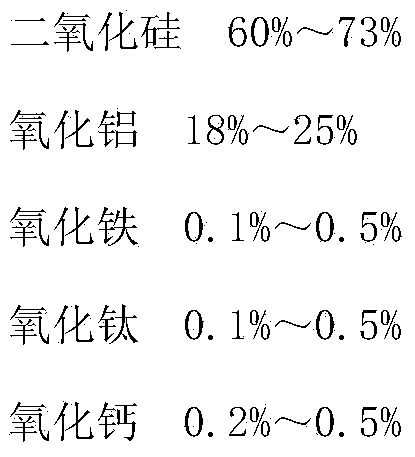

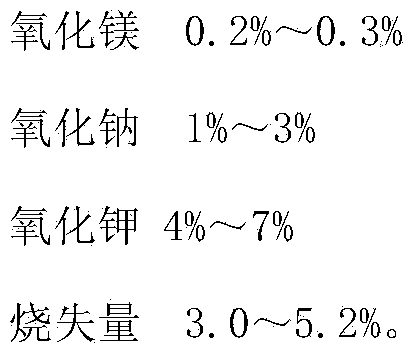

[0051] A kind of anticorrosion brick, its adobe body comprises the raw material composition of following parts by weight: 10 parts of Zhangzhou white clay, 6 parts of Xiadai white clay, 1 part of Zhangpu clay # 7 parts, 12 parts of washed kaolin, 10 parts of washed sand, 4 parts of Longshan albite # 3.5 parts, Longshan albite 2 # 10 parts, Changtai kaolin 2.0 parts, Longhai feldspar 1 # 15 parts, 15 parts of Daping stone rice, 5 parts of bentonite, 2 parts of Zhangpu soil # (lime soil) 4 parts.

Embodiment 2

[0053] An anti-corrosion brick, comprising a brick body and a glaze, the brick body comprising the following raw materials in parts by weight: 10 parts of Zhangzhou white clay, 6 parts of Xiadai white clay, 1 part of Zhangpu clay # 7 parts, 12 parts of washed kaolin, 10 parts of washed sand, 4 parts of Longshan albite # 3.5 parts, Longshan albite 2 # 10 parts, Changtai kaolin 2.0 parts, Longhai feldspar 1 # 15 parts, 15 parts of Daping stone rice, 5 parts of bentonite, 2 parts of Zhangpu soil # (lime soil) 4 parts; Its glaze material comprises the raw material composition of following parts by weight: TTKG556 86 parts, aluminum oxide 5 parts, corundum (aluminum oxide (Al 2 o 3 ) 7 parts, CMC (sodium carboxymethyl cellulose) 0.3 parts, STPP (industrial sodium tripolyphosphate) 0.7 parts.

[0054] Its performance index of anticorrosion brick provided by the present invention is as follows: (see table one)

[0055] Table I:

[0056]

[0057]

preparation Embodiment 2

[0059] A kind of concrete steps for preparing the anticorrosion brick described in embodiment 2 is:

[0060] a) selection of raw materials, mixing according to the raw materials and their proportions described in Example 2;

[0061] b) Ingredients, weigh the ingredients according to the formula requirements (the deviation range of single material is 30kg / time);

[0062] c) ball milling, material: ball: water = 1:1:0.8 ratio for canned ball milling, ball milling time 10-12 hours, ball milling fineness 1.2%-1.8% (250 mesh screen);

[0063] d) Preparation of mud, after the mud passes through an 80-mesh sieve, it enters the iron removal system to remove iron, and after iron removal, the mud is stored in the slurry barrel for stale use;

[0064] e) Spray milling, sieve the mud to remove iron and then spray milling, the powder is sieved to remove iron and put into the powder tank for stale use. 25%, less than 10% under 100 mesh;

[0065] f) Brick pressing, evenly distributing sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com