Drill positioning guider

A positioning guide and positioning block technology, which is applied in the direction of positioning measurement in the boring machine/drilling machine, drilling/drilling equipment, components of the boring machine/drilling machine, etc. To meet the requirements of aircraft assembly accuracy and other issues, to achieve the effect of convenient operation, simple structure, improved processing accuracy and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is described below in conjunction with accompanying drawing:

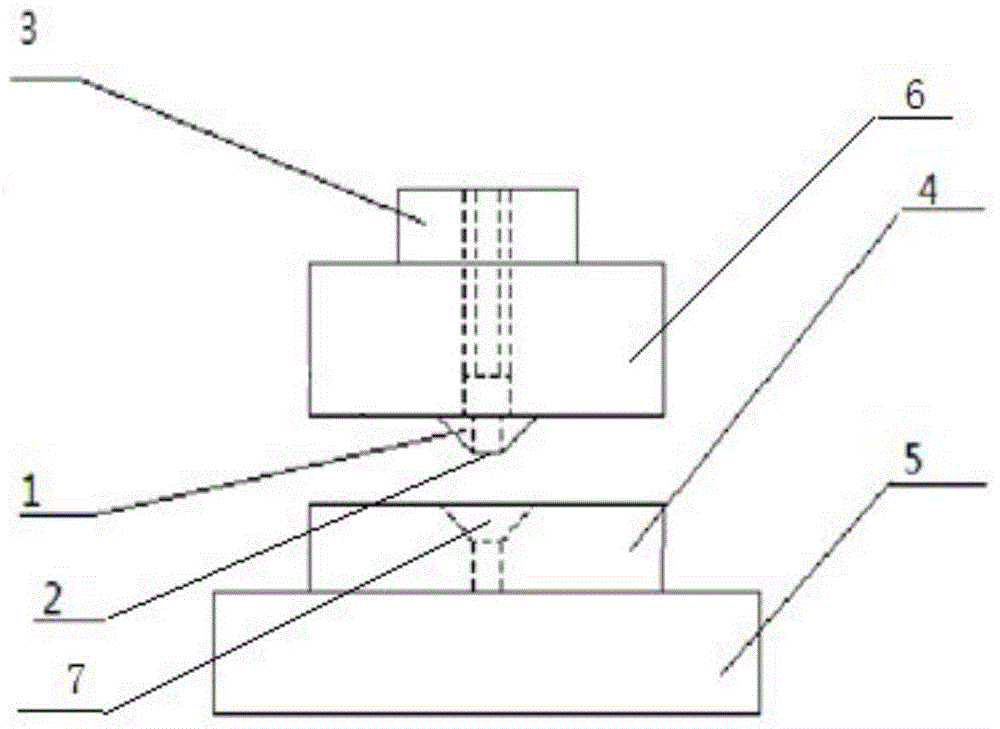

[0010] The drilling positioning guide includes a positioning block 1, a mounting seat 6, and a guide block 3, and is characterized in that: the positioning block 1 is in the shape of a rounded table with a hole in the center, and the small end of the positioning block 1 can be inserted into the prefabricated nail socket In 7, the bottom surface of the small head end is the positioning surface 2, and the positioning surface 2 is perpendicular to the normal direction of the bottom surface of the prefabricated nail pocket 7 of the part to be processed, and the shape of the positioning block 1 matches the shape of the prefabricated nail pocket 7; the center of the guide block 3 is drilled. There is a hole, the center hole of the guide block 3 is matched with the drill bit used in the drilling process, one end of the guide block 3 is connected with the big end of the positioning block 1, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com