A kind of inner flanging mold and flanging process of double-layer annular parts

A technology of ring parts and inner flanging, which is applied in the field of mechanical processing to achieve the effect of ensuring the processing size, good effect and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

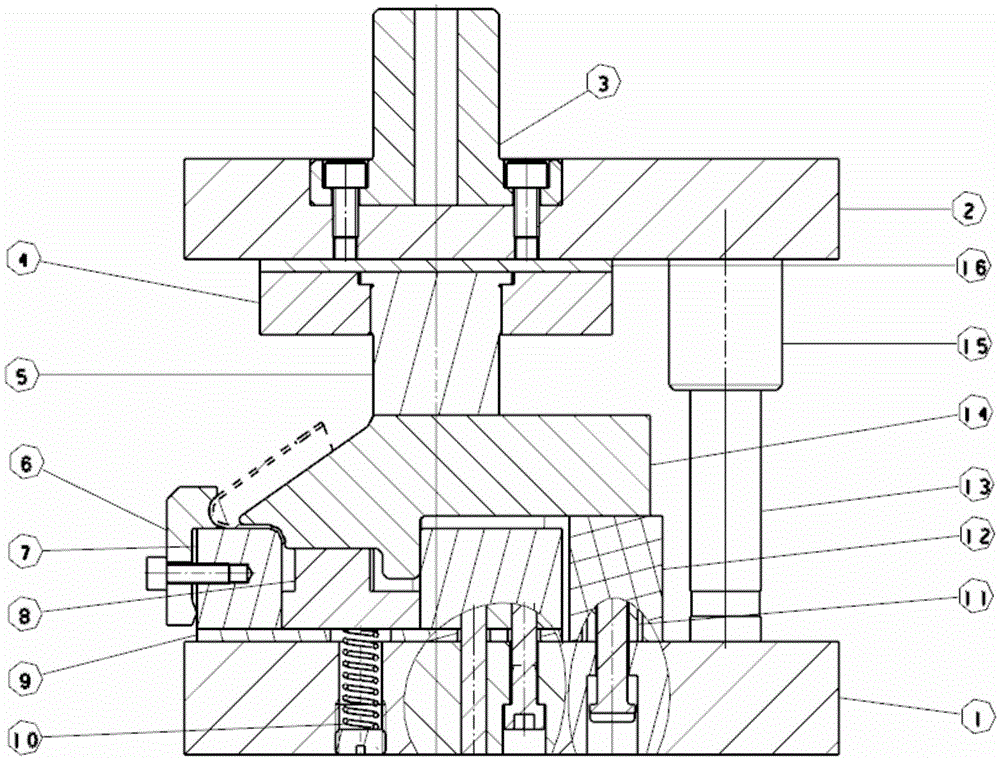

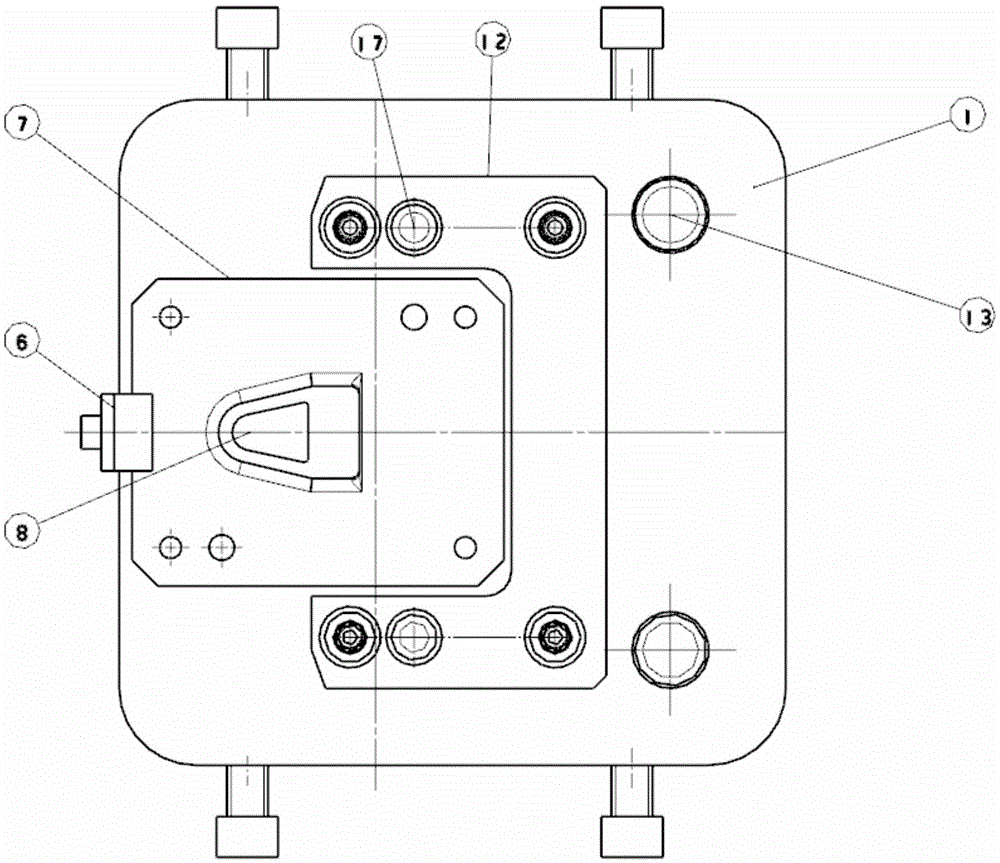

[0017] This embodiment provides a double-layer ring inner flanging mold, which is characterized in that: the double-layer ring inner flanging mold includes a lower template 1, an upper template 2, a mold handle 3, a fixing plate 4, a press Block 5, pressing plate 6, die 7, positioning block 8, lower backing plate 9, spring 10, limit sleeve 11, shock absorber 12, guide post 13, punch 14, guide sleeve 15, upper backing plate 16, small guide post 17;

[0018] The mold handle 3 is connected with the upper template 2 through four screws, the mold and the punch are connected by the mold handle 3, the pressing block 5 is fixed on the upper template 2 by the fixed plate 4, and the fixed plate 4 and the upper backing plate 16 are Connect with the upper formwork 2 through screws and pins; the die 7 is connected with the lower formwork 1 through screws and pins; the pressure plate 6 is connected with the die 7 through a screw, and the positioning block 8 is contained in the cavity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com