Concave extrusions for non-ferrous metals

An extrusion device, non-ferrous metal technology, applied in metal extrusion, metal extrusion dies, metal processing equipment and other directions, can solve the problems of waste of finished materials, reduce product yield, long shrinkage and other problems, and improve the yield of finished products. , The effect of improving the yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

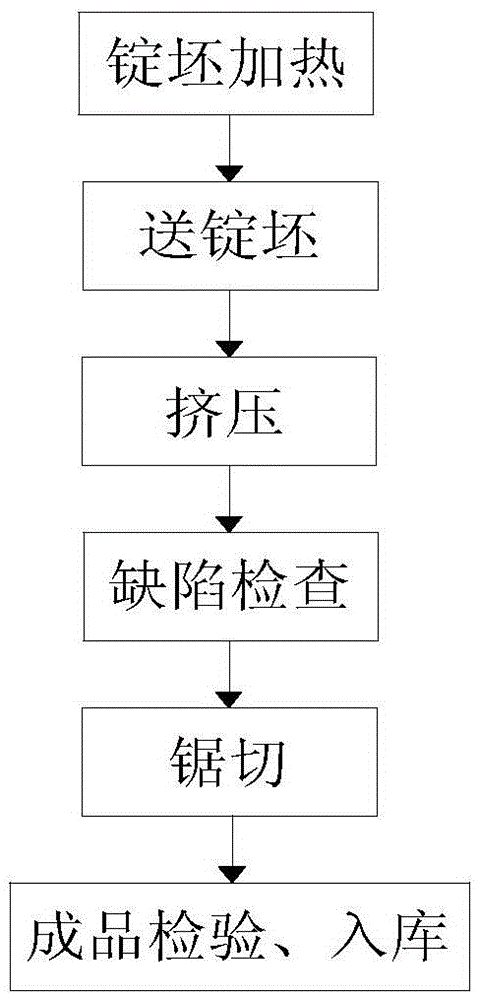

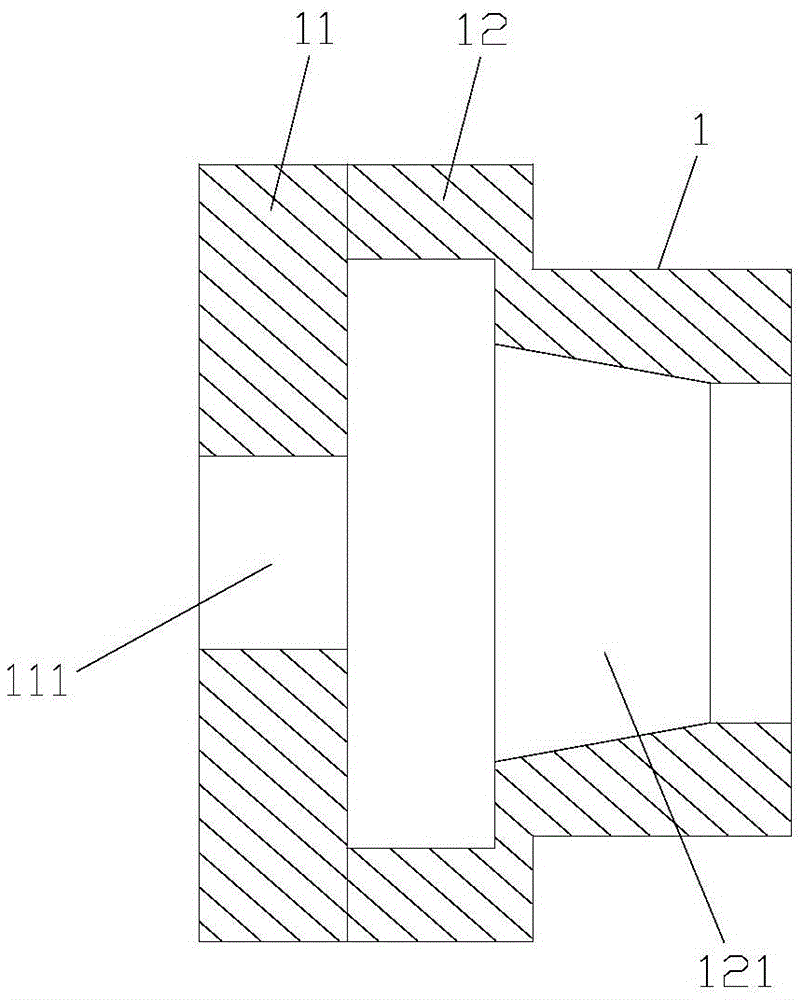

[0024] Such as figure 1 As shown, the present invention is applicable to the concave extrusion method of non-ferrous metals, which is to increase the metal volume in the central area and form a reverse resistance against the metal flow forming the shrinkage, specifically in the traditional double-plane circle (including square, heterosexual ) The central area of the working end surface of the flat plate shape extrusion pad forms a concave curved surface shape symmetrical to the center (or center line). In the process of extrusion deformation, the extrusion pad is used to form the convex surface of the blank to be deformed. The degree of forcing changes the deformation of the metal.

[0025] The non-ferrous metals involved in the present invention include copper, aluminum, zinc, lead and the like.

[0026] The specific implementation process (taking copper and copper alloy as an example) is as follows:

[0027] 1) Heating the ingot to a temperature of 600°C to 950°C require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com