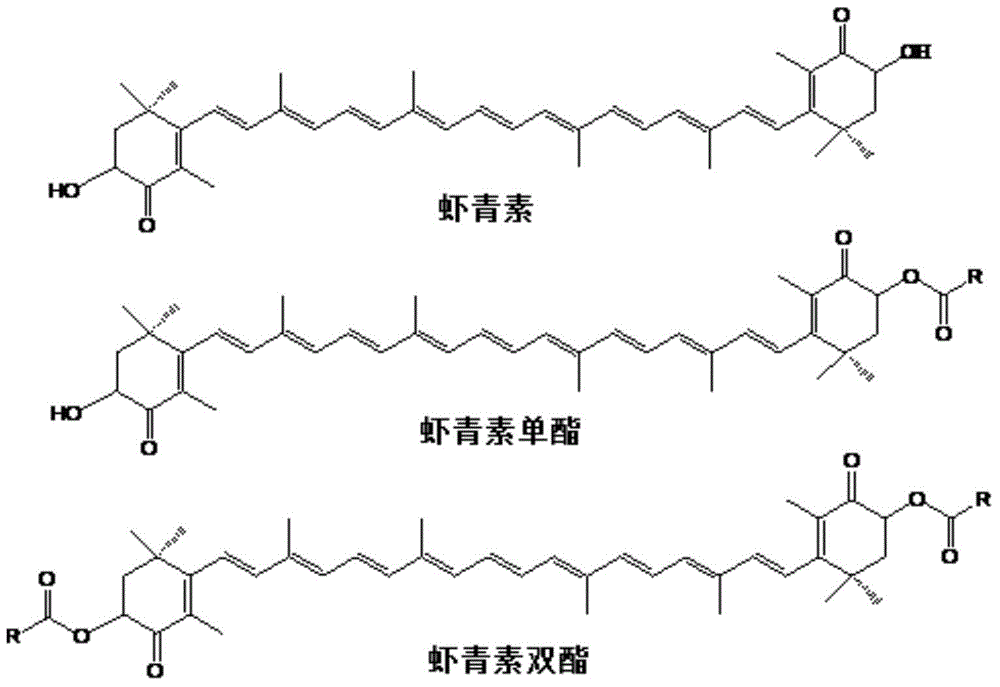

High-stability astaxanthin ester self-microemulsion and preparation method thereof

A technology of astaxanthin ester and self-microemulsion, which is applied in the directions of food preparation, pharmaceutical formulation, emulsion delivery, etc., can solve the problems of poor water solubility and poor storage stability of astaxanthin ester, and achieves good stability and simple production process. , the effect of inhibiting degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

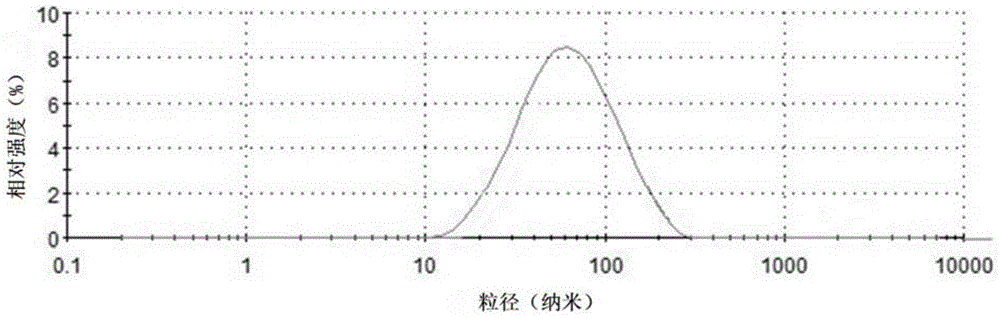

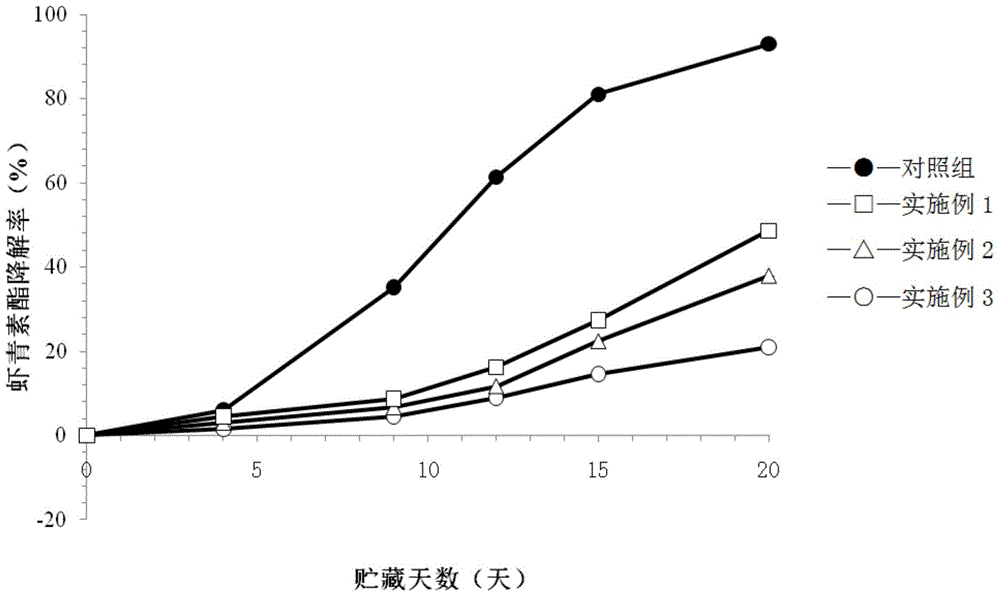

[0035] Using the astaxanthin ester crude extract derived from Haematococcus pluvialis as raw material, wherein the astaxanthin ester content is 7% (purchased from Yunnan Aierfa Biological Engineering Co., Ltd.), weigh 1g of the astaxanthin ester crude extract and 0.1g of tocopheryl acetate, then dissolved in 3ml of ethyl acetate to make astaxanthin ester-tocopheryl acetate-ethyl acetate solution; take 1ml of the above astaxanthin ester-tocopheryl acetate-ethyl acetate Add 4ml of mixed emulsifier (Tween 80 / ethanol 2:1) to the ester solution, stir evenly at 40°C, then add 10ml of pH7.0 phosphate buffer solution, and homogenize at high speed to obtain high-stable astaxanthin ester From the microemulsion, observe the appearance of the system and measure the particle size and stability, the results are as follows: the emulsion appearance is clear and transparent, and the average particle size distribution is 61nm (such as figure 2 Shown), illustrate that the present embodiment 1 p...

Embodiment 2

[0037] The astaxanthin ester crude extract derived from Haematococcus pluvialis was used as raw material, wherein the astaxanthin ester content was 7% (purchased from Yunnan Aierfa Bioengineering Co., Ltd.), and 1g of the astaxanthin ester crude extract was weighed, Then dissolve it with 3ml of ethyl acetate to form astaxanthin ester-ethyl acetate solution; take 1ml of the above astaxanthin ester-ethyl acetate solution, add 4ml of mixed emulsifier (Tween 80 / ethanol 2:1), and Stir evenly at 40°C, then add 10ml of pH 7.0 phosphate buffer solution pre-dissolved with 0.1g of ascorbic acid, homogenize at high speed to obtain a highly stable astaxanthin ester self-microemulsion, observe the appearance of the system and measure the particle size and stability properties, the results are as follows: the emulsion appearance is clear and transparent, and the average particle size distribution is 65nm, indicating that the present embodiment 1 prepares a highly water-soluble self-microemul...

Embodiment 3

[0039]The astaxanthin ester crude extract derived from Haematococcus pluvialis was used as raw material, wherein the astaxanthin ester content was 7% (purchased from Yunnan Aierfa Bioengineering Co., Ltd.), and 1g of the astaxanthin ester crude extract was weighed, Then dissolve it with 3ml of ethyl acetate to form astaxanthin ester-ethyl acetate solution; take 1ml of the above astaxanthin ester-ethyl acetate solution, add 4ml of mixed emulsifier (Tween 80 / ethanol 2:1), and Stir evenly at 40°C, then add 10ml of pH 7.0 phosphate buffer solution pre-dissolved with 0.1g of ethylenediaminetetraacetic acid, homogenize at high speed to obtain a highly stable astaxanthin ester self-microemulsion, observe the appearance of the system and measure Particle size and stability, the results are as follows: the emulsion appearance is clear and transparent, and the average particle size distribution is 63nm, illustrating that the present embodiment 1 prepares a highly water-soluble self-micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com