Production method of germinated brown rice puffed cake

A technology of germinated brown rice and its production method, which is applied in the field of food processing, can solve the problems of poor eating quality of germinated brown rice, achieve the effects of enriching varieties, reducing moisture content, and promoting long-term memory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

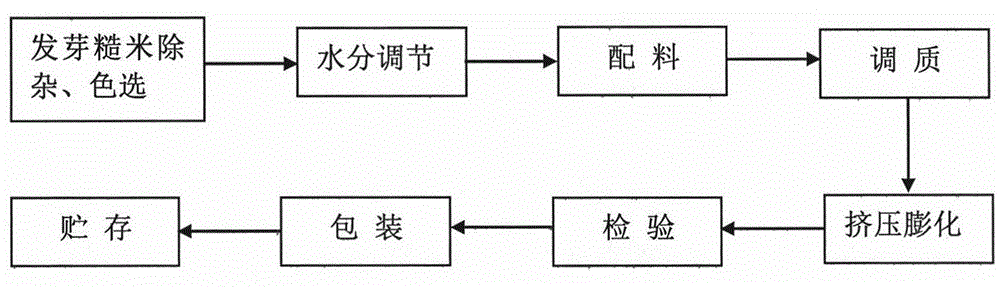

Method used

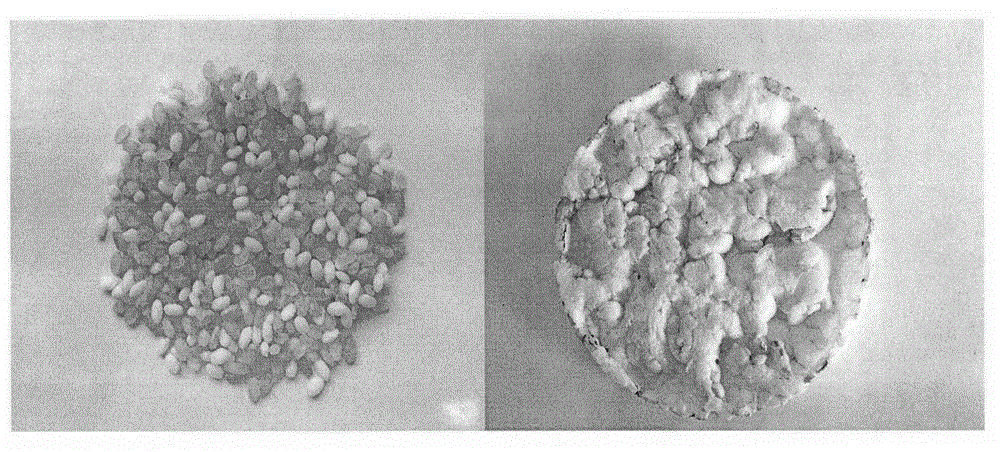

Image

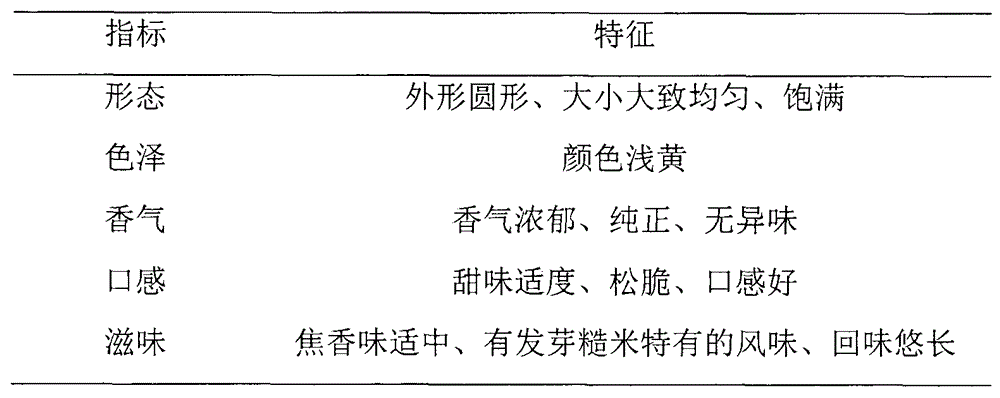

Examples

Embodiment 1

[0030] (1) Impurity removal and color sorting: use a grain grading sieve to remove impurities and color sort the raw material germinated brown rice, and screen out high-quality germinated brown rice with uniform particle size and normal color;

[0031] (2) Moisture adjustment: add water to high-quality germinated brown rice and high-quality glutinous rice spray, so that its moisture content is controlled at 14%;

[0032] (3) Ingredients: by weight, take 70g of conditioned high-quality germinated brown rice, 20g of glutinous rice, 2g of vegetable oil, 4g of white granulated sugar powder, and 4g of maltodextrin and place them in a mixing tank and mix them evenly;

[0033] (4) Tempering: put the uniformly mixed material in a sealed bag for conditioning overnight, and then it will become a puffed material;

[0034] (5) Puffing: put the conditioned puffed material in a SW-990 type puffing machine for puffing treatment, control the temperature of the puffing machine to 250°C, adjust...

Embodiment 2

[0039] (1) Impurity removal and color sorting: use a grain grading sieve to remove impurities and color sort the raw material germinated brown rice, and screen out high-quality germinated brown rice with uniform particle size and normal color;

[0040] (2) Moisture adjustment: add water to high-quality germinated brown rice and high-quality glutinous rice spray, so that its moisture content is controlled at 16%;

[0041] (3) Ingredients: by weight, take 50g of conditioned and tempered high-quality germinated brown rice, 40g of glutinous rice, 3g of vegetable oil, 4g of white granulated sugar powder, and 3g of maltodextrin and place them in a mixing tank and mix them evenly;

[0042] (4) Tempering: put the uniformly mixed material in a sealed bag for conditioning overnight, and then it will become a puffed material;

[0043] (5) Expansion: place the conditioned puffed material in a SW-990 type puffing machine for puffing treatment, control the temperature of the puffing machine...

Embodiment 3

[0048] (1) Impurity removal and color sorting: use a grain grading sieve to remove impurities and color sort the raw material germinated brown rice, and screen out high-quality germinated brown rice with uniform particle size and normal color;

[0049] (2) Moisture adjustment: add water to high-quality germinated brown rice and high-quality glutinous rice spray, so that its moisture content is controlled at 18%;

[0050] (3) Ingredients: by weight, take 30g of conditioned and tempered high-quality germinated brown rice, 60g of glutinous rice, 3g of vegetable oil, 5g of white granulated sugar, and 2g of maltodextrin and place them in a mixing tank and mix them evenly;

[0051] (4) Tempering: put the uniformly mixed material in a sealed bag for conditioning overnight, and then it will become a puffed material;

[0052] (5) Puffing: put the conditioned puffed material in a SW-990 type puffing machine for puffing treatment, control the temperature of the puffing machine to 230°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com