Instant black rice porridge and processing method thereof

A processing method and technology of instant porridge, which is applied in the field of black rice instant porridge and its processing, can solve the problems of inability to present traditional porridge, poor sensory quality, and poor rehydration, and achieve simplified processing technology, energy saving, and rehydration Good, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

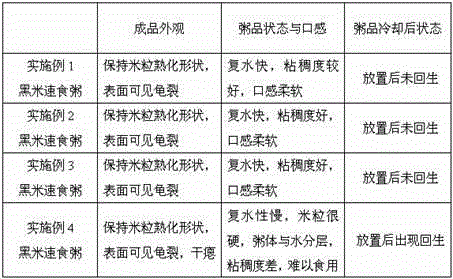

Examples

Embodiment 1

[0014] Black rice with an amylose content of 6.41%, an amylose molecule consisting of 260 glucose residues, a gelatinous consistency of 94.7mm, and a gelatinization temperature of 67°C was screened from fresh brown rice samples collected from commercially available black rice production bases. . When the rice is mature, wind selection is carried out after harvesting in the afternoon on a sunny day to remove the residual branches and leaves of the rice straw, and at the same time remove the unbound water on the rice husk, and then grind the rice husk to obtain fresh brown rice. Black rice Fresh brown rice is soaked in water 3 times its weight for 6 hours, then steamed for 15 minutes, kept warm for 40 minutes, then separated, spread out and microwaved for 6 minutes, and then dried with hot air at 80°C for 40 minutes to obtain black rice speed porridge. The instant porridge produced can be eaten after brewing in boiling water for 5-8 minutes without additional heating.

Embodiment 2

[0016] Black rice with an amylose content of 4.74%, an amylose molecule consisting of 140 glucose residues, a gelatinous consistency of 87.7mm, and a gelatinization temperature of 62°C was screened from fresh brown rice samples collected from commercially available black rice production bases. . When the rice is mature, wind selection is carried out after harvesting in the afternoon on a sunny day to remove the residual branches and leaves of the rice straw, and at the same time remove the unbound water on the rice husk, and then grind the rice husk to obtain fresh brown rice. Black rice Fresh brown rice is soaked in water 2.2 times its weight for 5 hours, then steamed for 10 minutes, kept warm for 40 minutes, then separated, spread out and microwaved for 3 minutes, and then dried with hot air at 80°C for 35 minutes to obtain black rice speed porridge. The instant porridge produced can be eaten after brewing in boiling water for 5-8 minutes without additional heating.

Embodiment 3

[0018] The black rice line "Fuzi 917" was used as the raw material, which was the "Nantan84" rice plant in the meiotic stage 60 Co-gamma ray 0.5 million roentgen radiation, M 1 A total of 161 strains with different mutant strains such as ripening stage were selected for generations, and the "triple selection" of "field pedigree selection", "indoor rice quality test" and "taste evaluation" was carried out for 5 consecutive generations in Fuzhou, Zhao'an, Minhou and other places. The amylose content of fresh brown rice is 0.70%, the amylose molecule is composed of 100 glucose residues, the gelatinous consistency is 101.7mm, and the gelatinization temperature is 55°C. When the rice is mature, wind selection is carried out after harvesting in the afternoon on a sunny day to remove the residual branches and leaves of the rice straw, and at the same time remove the unbound water on the rice husk, and then grind the rice husk to obtain fresh brown rice. Black rice Fresh brown rice i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com