Sugar cane harvester and sugar cane harvesting method

A harvester and sugarcane technology, applied to harvesters, agricultural machinery and tools, agriculture, etc., can solve the problems of low efficiency, avoid entanglement of sugarcane leaves, solve jamming, and save the time and frequency of U-turns in the field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. First of all, it should be pointed out that the present invention takes the harvesting direction of the harvester as the front.

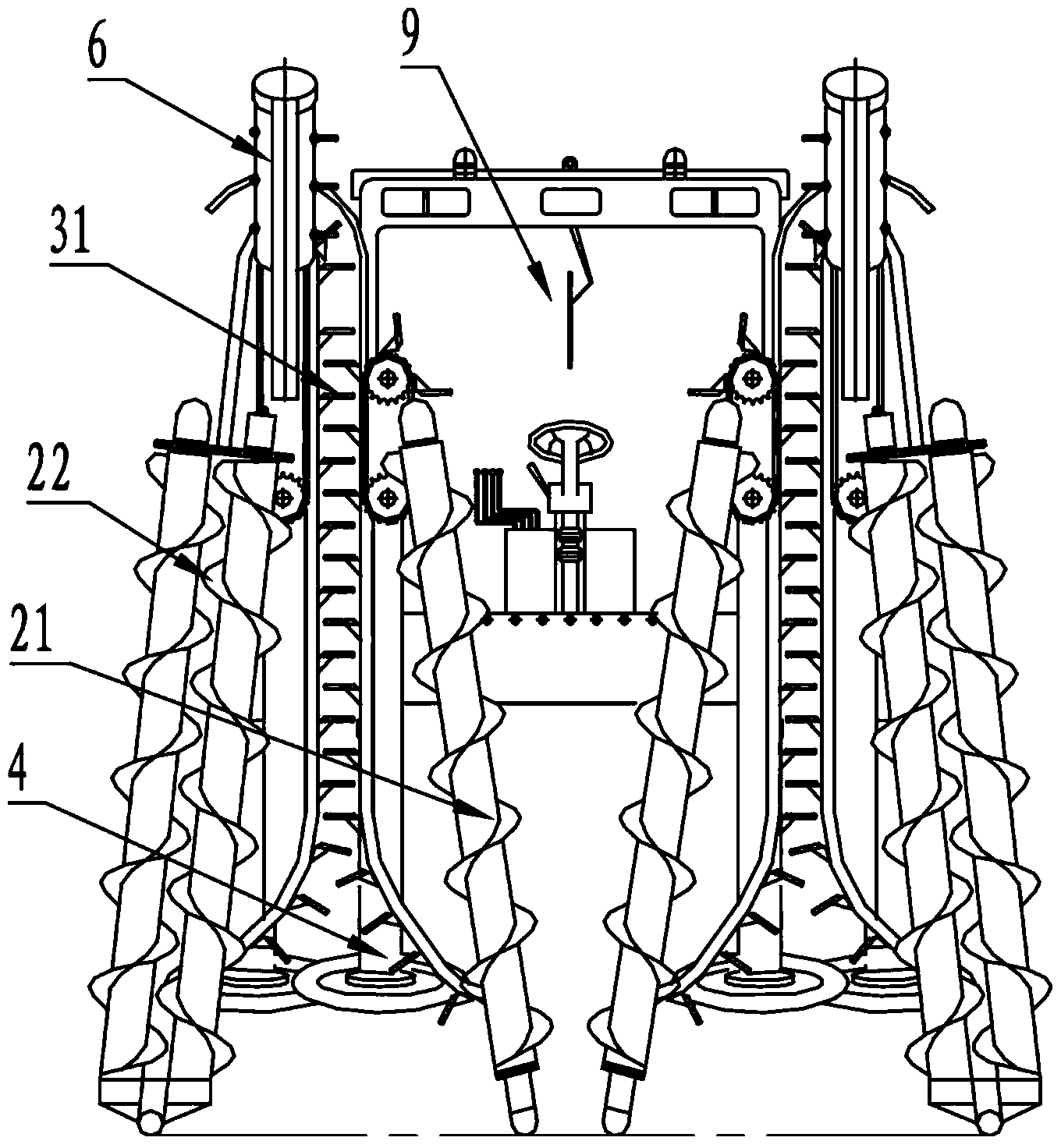

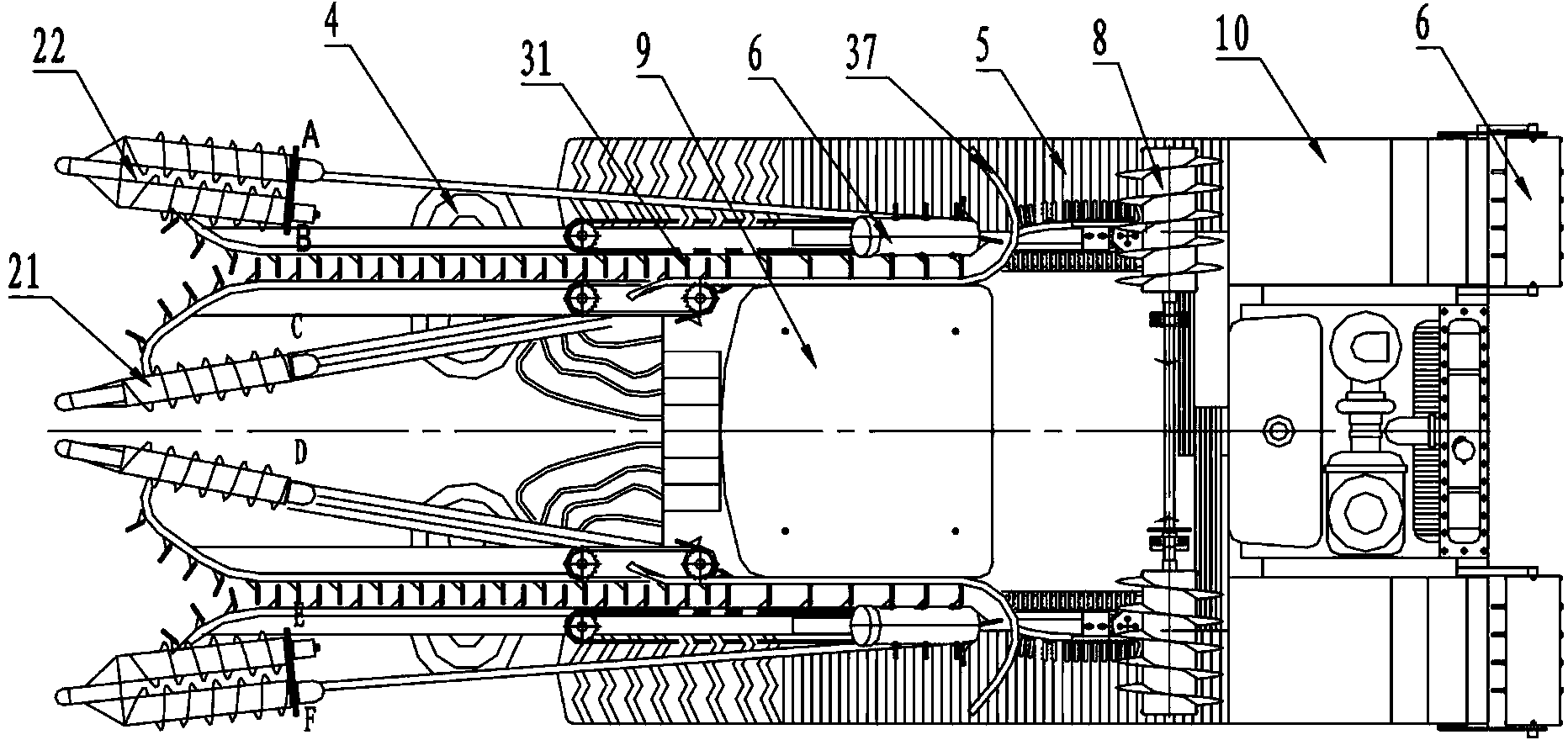

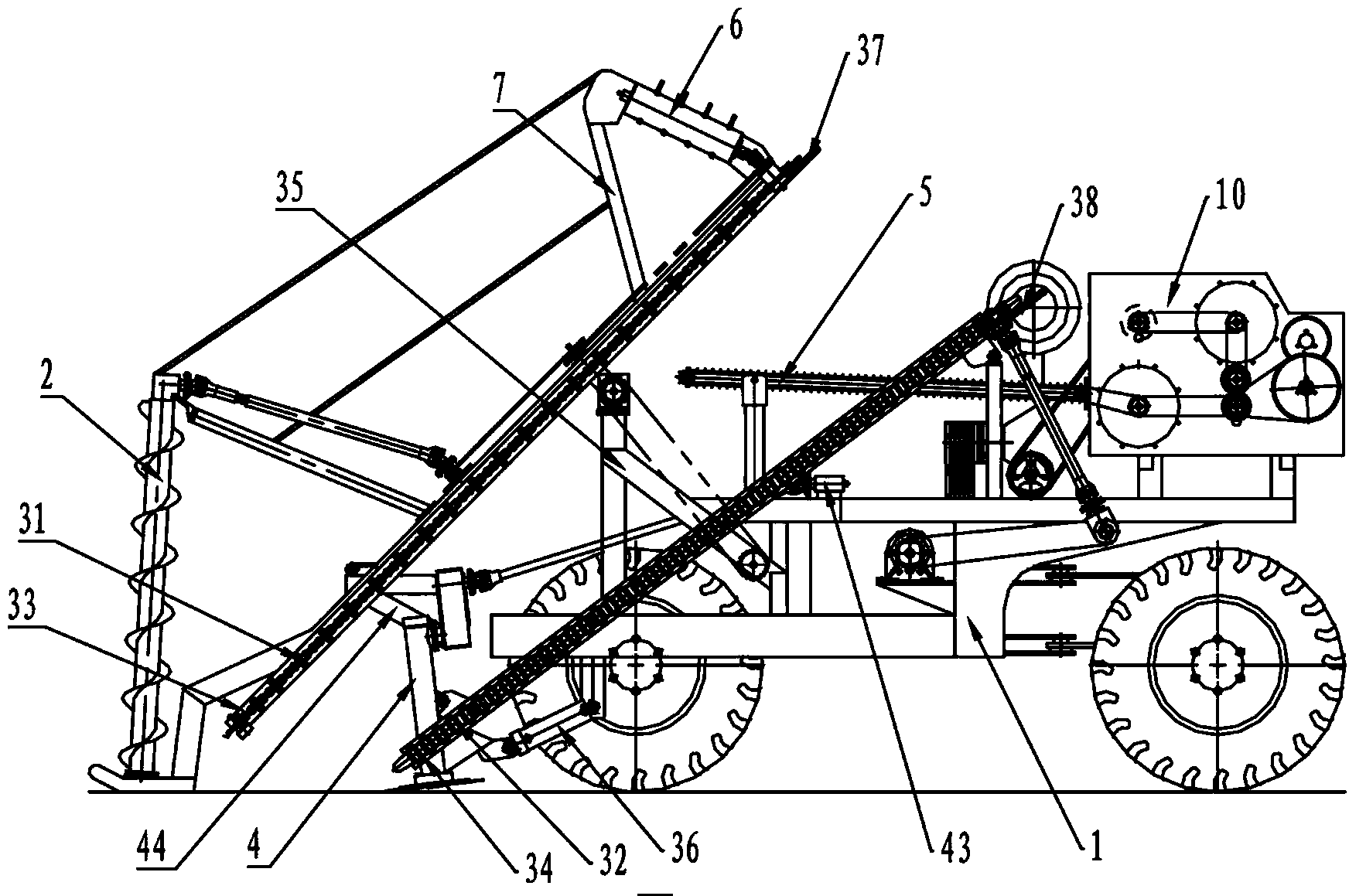

[0036] Such as figure 1 and image 3Shown, a kind of sugarcane harvester of the embodiment of the present invention, it comprises body 1 and two groups of harvesting mechanism, and these two groups of harvesting mechanisms are symmetrically arranged on the both sides of body 1, and each group of harvesting mechanism comprises spiral cane holding device 2, Clamping device 3, cutting device 4, conveying mechanism 5 and leaf stripper 10, clamping device 3 comprises upper clamping chain 31 and lower clamping chain 32, forms clamping chain between up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com