Test structure and test method of time dependent dielectric breakdown

A technology of test structure and test method, which is applied in the direction of test dielectric strength, etc., can solve the problems such as the decline of TDDB performance and the inability to evaluate it well, and achieve the effect of simple test structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

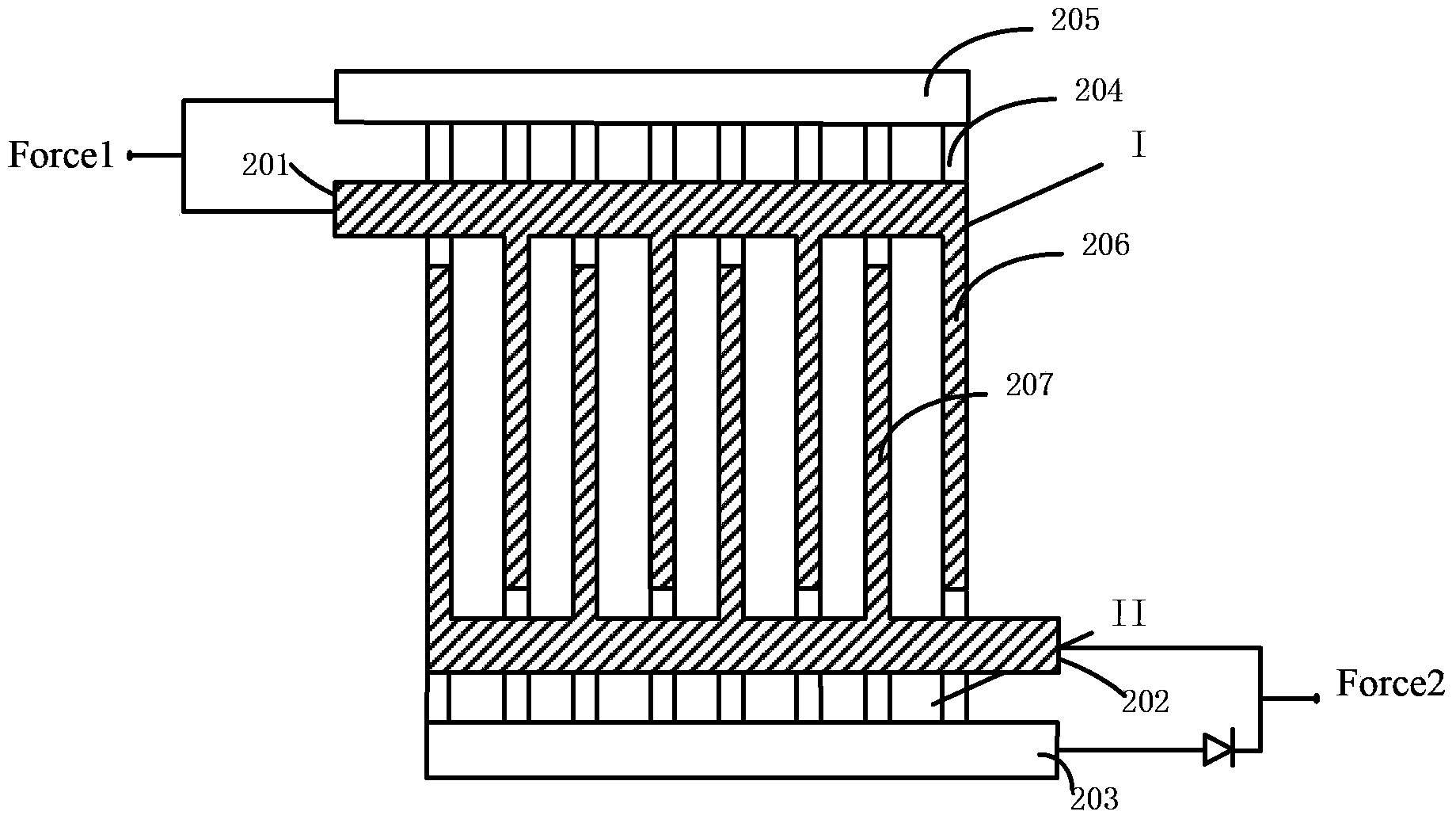

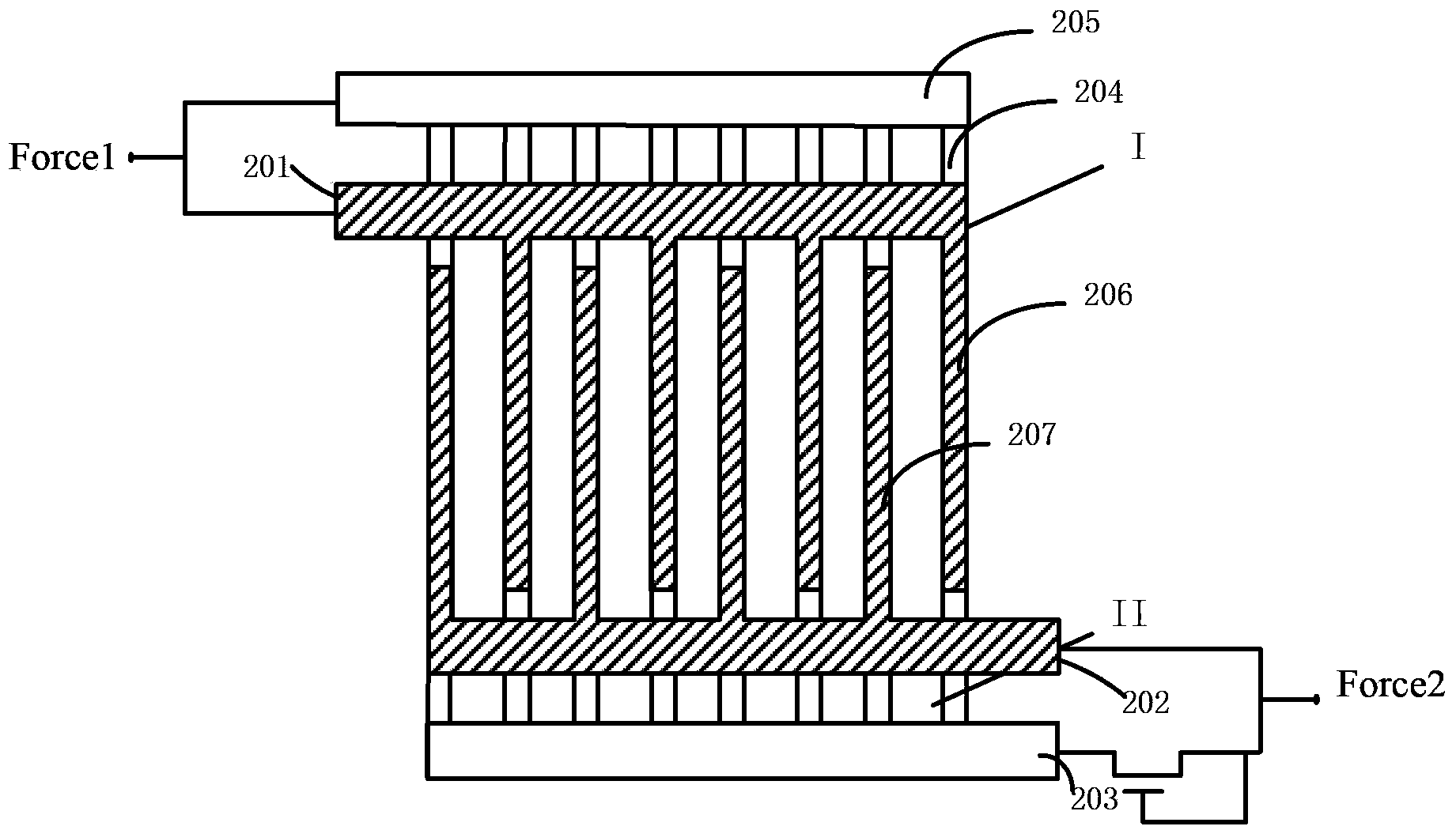

[0064] In this example, if Figure 2a As shown, the resistor array unit and the test unit are arranged in parallel with a metal dielectric layer between them to isolate the resistor array unit and the test unit.

[0065] The size of the resistance wire in the resistance array sheet is the same as the size of the comb teeth in the test unit or the size of the serpentine bending test piece, so as to ensure that the heat generated by the resistance wire is better transferred to the test unit. The size of the resistance wires in the resistance array sheet is set in alignment with the comb teeth in the test unit.

[0066] The resistance array unit II includes a first connection line 205 and a second connection line 203 and a resistance line 204 between the first connection line 205 and the second connection line 203, the resistance line 204 connects the first The connection line 205 and the second connection line 203 are connected as a whole, wherein the resistance lines are arrang...

Embodiment 2

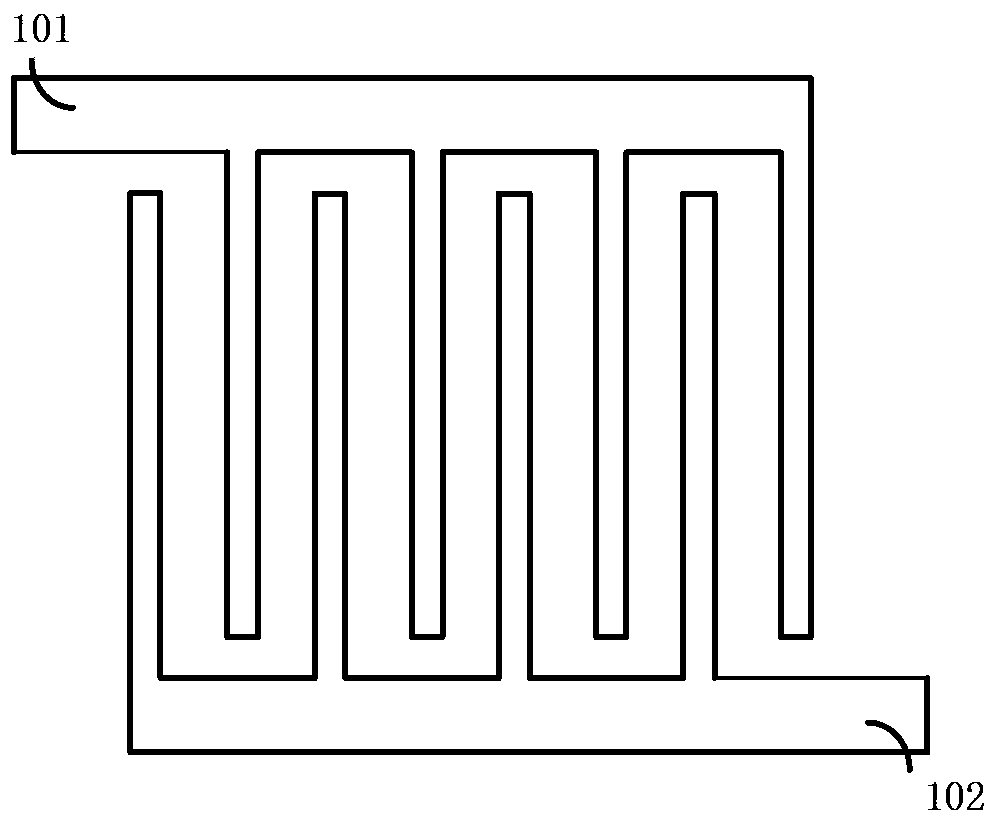

[0070] In this embodiment, the test unit includes a comb-shaped test piece and a serpentine-shaped test piece located on the same plane, the two test pieces are arranged oppositely, and the comb-shaped structure test piece has a plurality of conductive combs teeth, the serpentine-bent test piece is bent around the conductive comb, and the conductive comb is embedded in the bend.

[0071] Other structures and working principles are the same as in Embodiment 1.

Embodiment 3

[0073] In this example, if Figure 2a As shown, the resistor array unit and the test unit are arranged in parallel with a metal dielectric layer between them to isolate the resistor array unit and the test unit.

[0074] The size of the resistance wire in the resistance array sheet is exactly the same as the size of the comb teeth in the test unit or the size of the serpentine bending test piece, so as to ensure that the heat generated by the resistance wire is better transferred to the test unit. The size of the resistance wires in the resistance array sheet is set in alignment with the comb teeth in the test unit.

[0075] The resistance array unit II includes a first connection line 205 and a second connection line 203 and a resistance line 204 between the first connection line 205 and the second connection line 203, wherein the resistance line is vertically arranged, and There is a certain interval between the resistance lines 204, wherein the first connection line 205, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com