Equipment system fault integral diagnosis method and device

A system failure and comprehensive diagnosis technology, applied in the field of test engineering, can solve problems such as abnormal operation of equipment systems, impact on task execution, economic losses, etc., to reduce maintenance manpower and other support resources, improve accuracy and scientificity, The effect of reducing life cycle costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

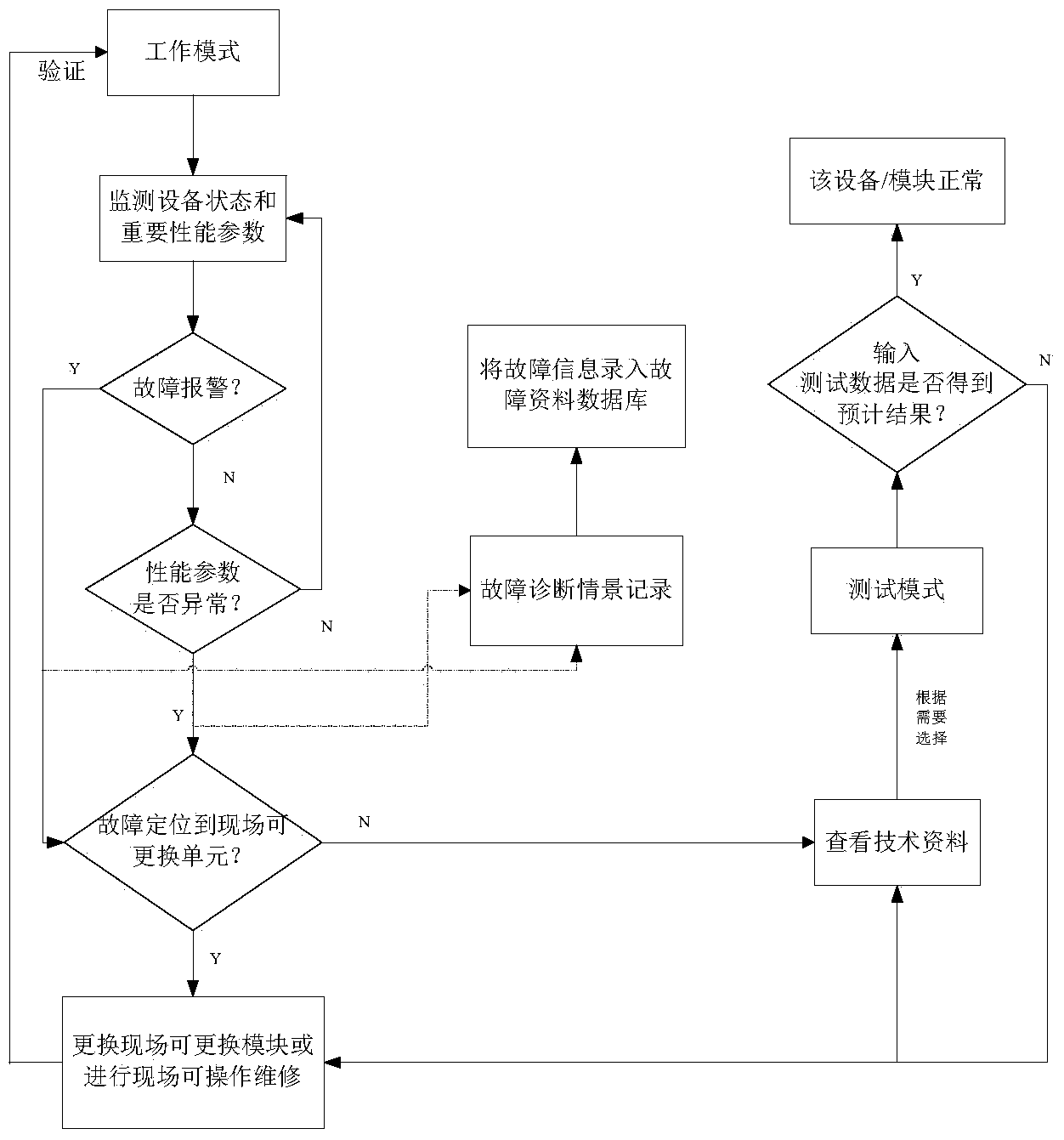

[0057] According to the equipment system fault comprehensive diagnosis method provided by the present invention, it includes two stages of working mode and test mode, wherein, the working mode stage includes steps 1-4, and the test mode stage includes steps 5-6. After the work item) is over, the operator can choose whether to enter the working mode stage according to actual needs. Specifically, each step is as follows:

[0058] Step 1: Monitor the equipment status and performance parameters of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com