Feeding machine of small-sized coal briquette boiler

A technology of feeder and coal block, which is applied in the field of small coal block boiler feeder, can solve the problems of inability to guarantee the stability of the furnace flame, affect industrial production, danger, etc., and achieve easy promotion, reduce the probability of accidents, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

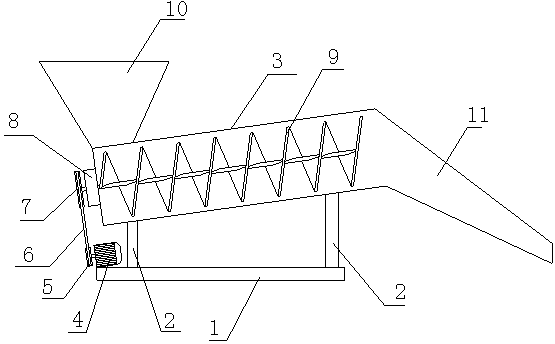

[0011] A small coal block boiler feeder, comprising a base 1, a bracket 2, a feed chamber 3 and a feed hopper 11, the base 1 is fixed with a feed chamber 3 placed obliquely through the bracket 2, and a motor 4 is fixed at one end of the base 1, The motor 4 is connected to the motor pulley 5, the motor belt 5 is connected to the feed pulley 7 through the belt 6, the feed pulley 7 is connected to the transmission 8, the transmission 8 is fixed on one end of the feeding chamber 3, the other end of the feeding chamber 3 is connected to the feeding hopper 11, and the transmission 8 is connected to the screw feeding shaft 9, the top of the feeding chamber 3 is fixed with a storage hopper 10, the motor 4 is a low-speed motor, the angle between the feeding chamber 3 and the base 1 is 10-15 degrees, the structure is simple, and the installation is convenient. During use, the fuel block can be added to the furnace at a stable speed, which ensures the stability of the flame in the furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com