Fluid Injector And Method For Operating Fluid Injector

A fluid injector and fluid injection technology, which is applied in the direction of fuel injection devices, fuel injection control, special fuel injection devices, etc., can solve problems such as the reduction of electrical signal amplitude, and achieve the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

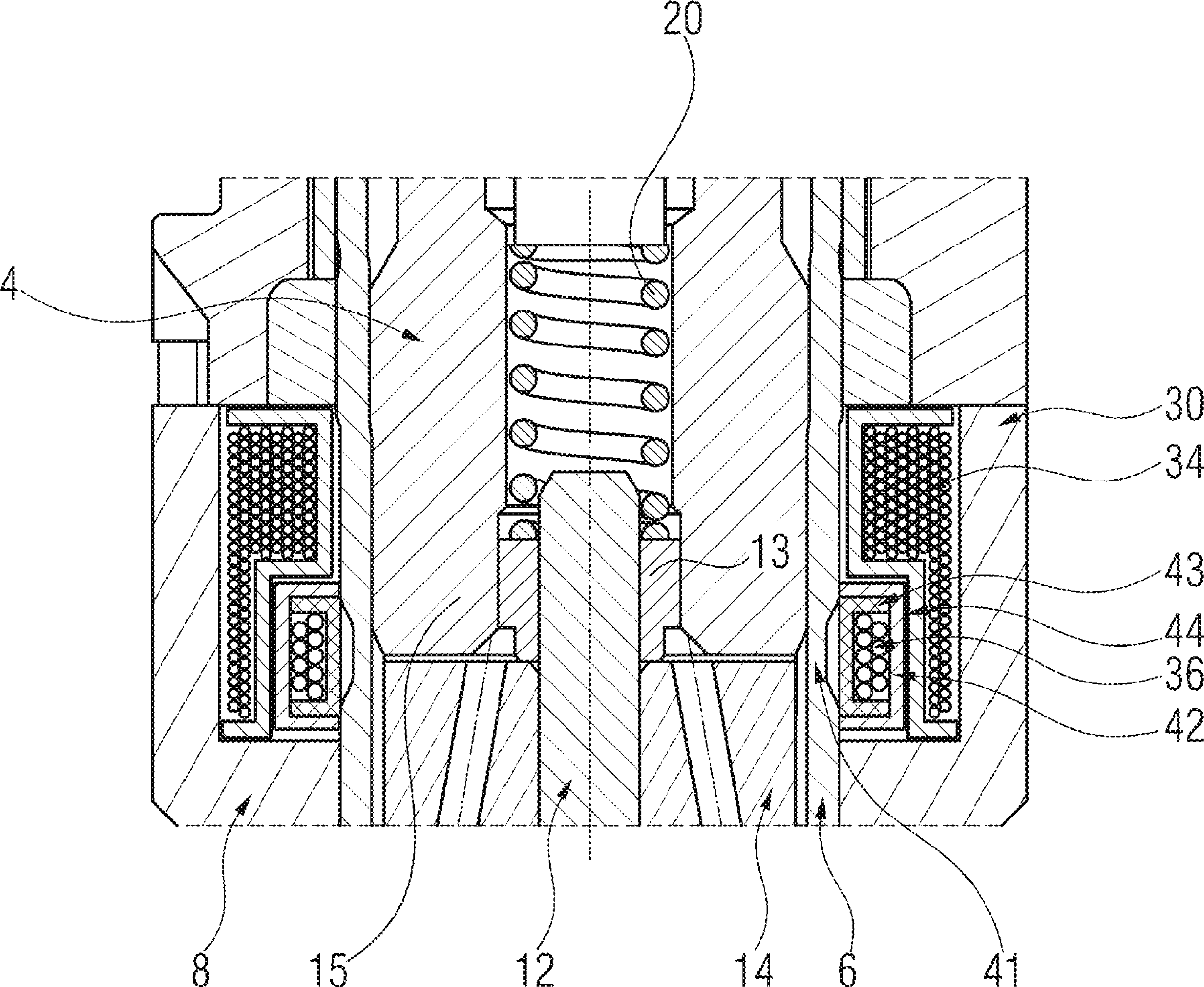

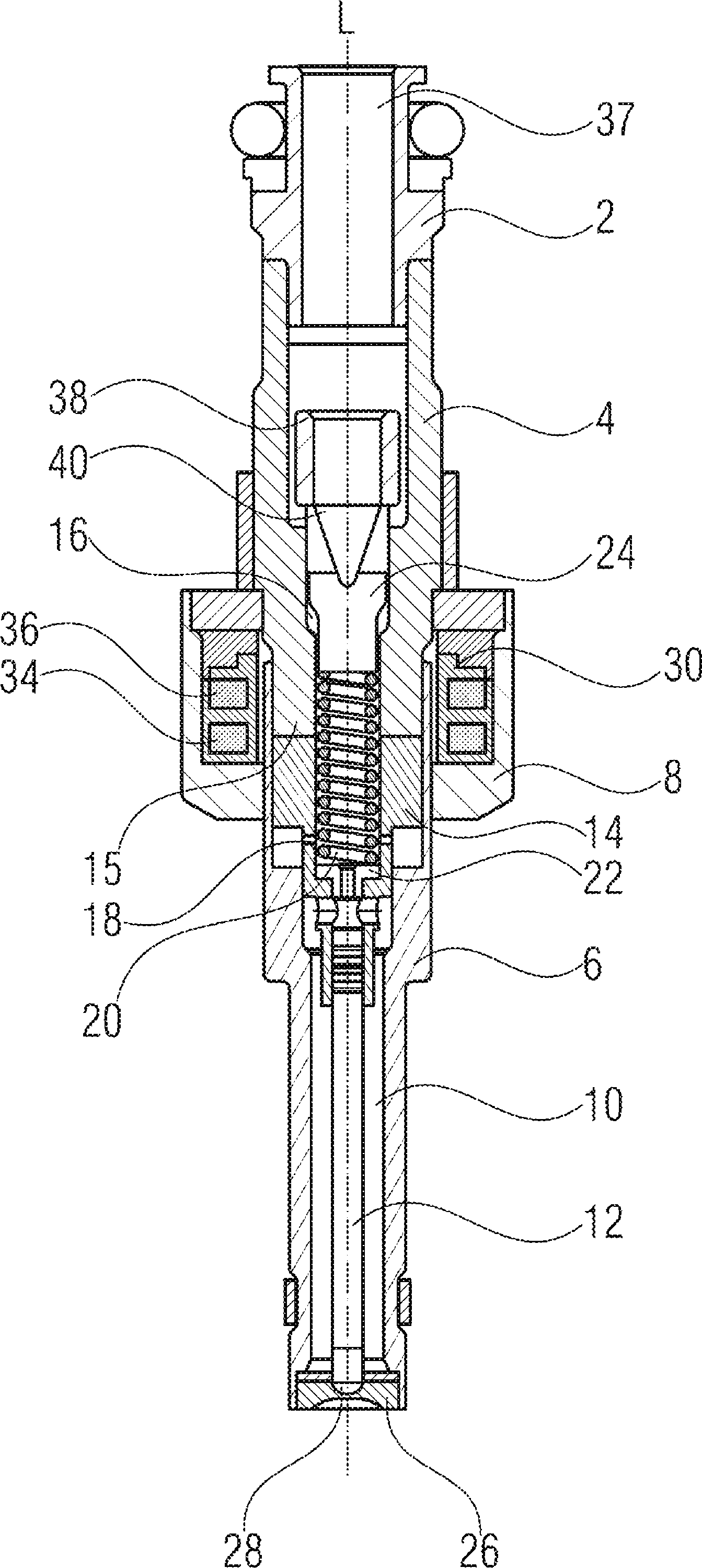

[0032] figure 1 A cross-sectional view of a known fluid injector is shown. The fluid injector is particularly suitable for dosing fluid, in particular fuel, into internal combustion engines. It comprises a fitting fitting 2 designed to mechanically and hydraulically couple the fluid injector to a fluid reservoir such as a fuel rail. The fluid injector has a longitudinal axis L and further comprises an inlet tube 4 , a valve body 6 and a housing 8 . Provided in the valve body 6 is a recess 10 which receives the valve needle 12 and preferably the armature 14 .

[0033] Valve needle 12 is mechanically coupled to armature 14 . in accordance with figure 1 In the case of a valve needle, the armature 14 is rigidly coupled to the valve needle 12 such that they are fixed in position relative to each other.

[0034] The inlet pipe 4 is provided with a recess 16 which hydraulically communicates with the recess 10 of the valve body 10 through a central opening 18 of the armature 14 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com