Fuel oil detecting device

A detection device and fuel technology, which is applied in the direction of measurement device, engine test, machine/structural component test, etc., can solve problems such as failure of engine oil into diesel oil, increase in spare parts cost, deterioration of engine performance, etc., and achieve simple calculation The effect of low handling, investment and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

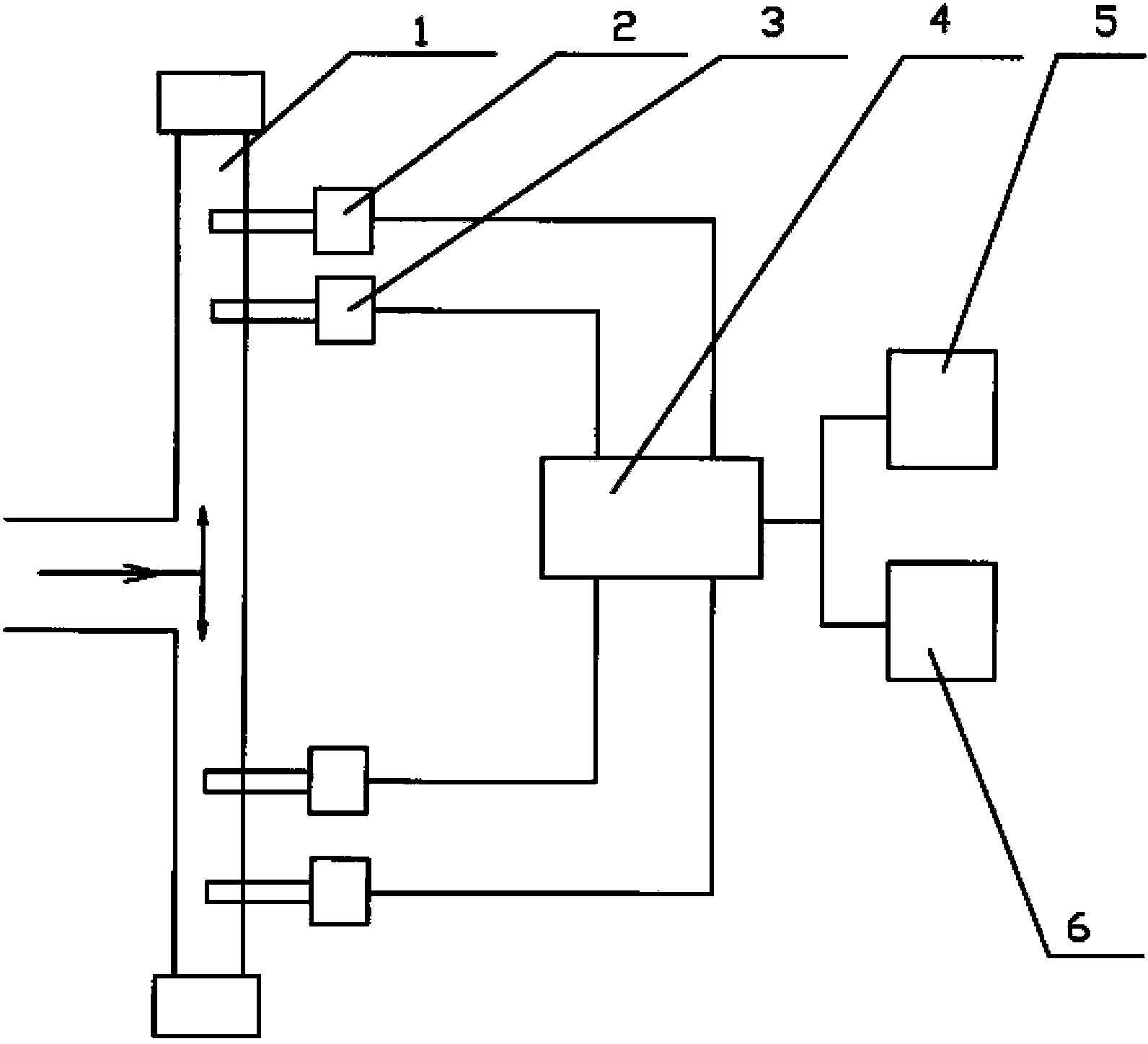

[0007] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0008] Such as figure 1 Shown: a fuel oil detection device, including a section of pipeline, characterized in that a pressure sensor and a flow sensor are installed on the pipeline, the middle of the pipeline is a U-shaped section, and the two sides are the first horizontal section and the second horizontal section , the free end of the first horizontal section is the connection end of the oil return pipe, and the free end of the second horizontal free section is provided with a gas quick connector, and the probes of the pressure sensor and the flow sensor enter the oil circuit and communicate with the data acquisition processor, data The display and the alar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com