Fluorescent dye and preparation method and application thereof

A technology for fluorescent dyes and acid dyes, applied in the field of fluorescent dyes and their preparation, can solve the problems of not meeting environmental protection requirements, waste of raw materials, low dye absorption rate, etc., and achieve the effects of rich color types, good vision and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

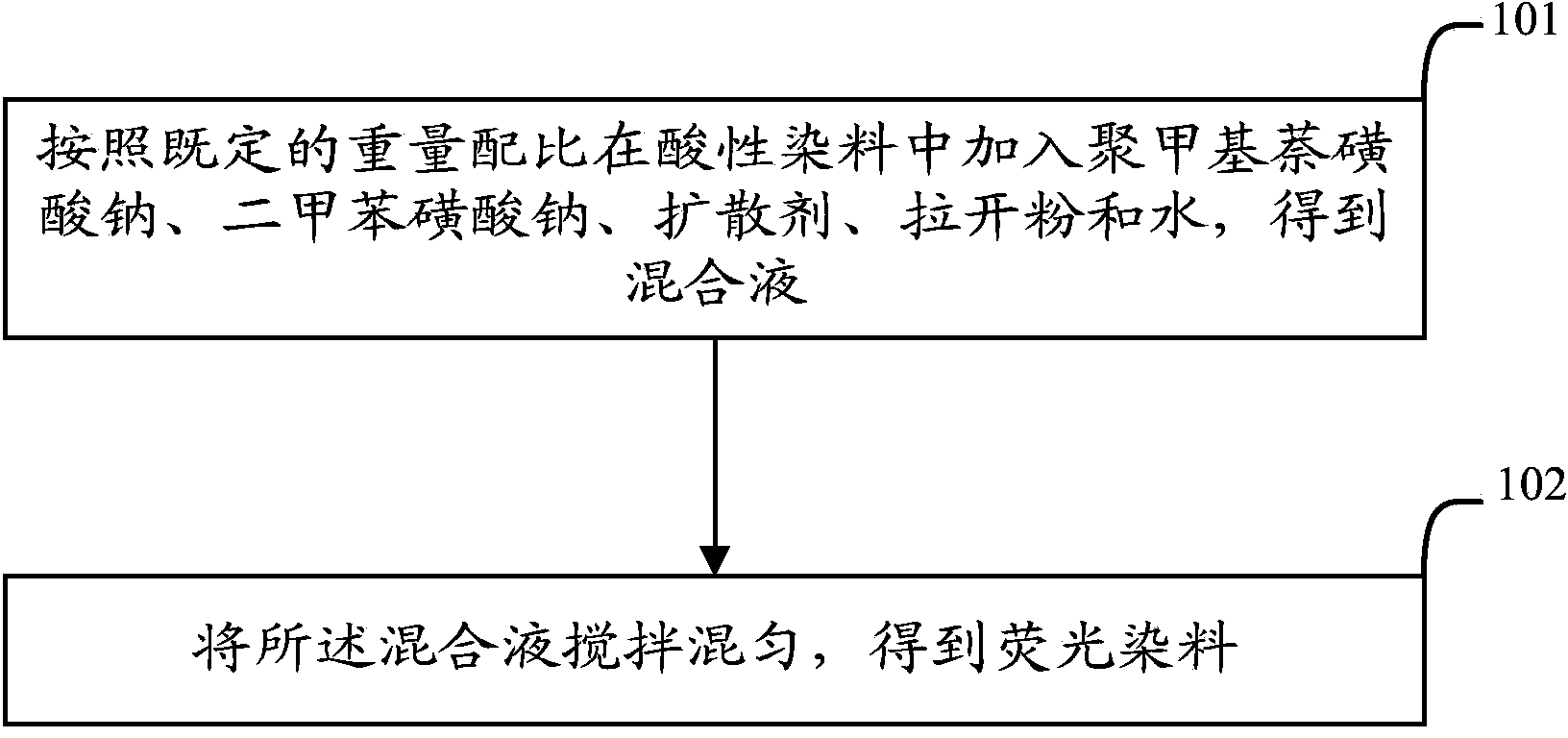

[0037] The fluorescent dye provided by the present invention contains an acid dye and auxiliary agents such as sodium polymethylnaphthalenesulfonate, sodium xylenesulfonate, diffusing agent, and pull-off powder in predetermined parts by weight. Among them, sodium polymethyl naphthalene sulfonate is used as an absorption aid, which can make the fur absorb the dye as much as possible, greatly improving the absorption rate of the fur to the dye; thus ensuring that the residual night after dyeing is in a colorless state . Sodium xylene sulfonate is a solubilizing conditioning additive, which is beneficial to the effective dissolution of each additive component. Diffusion agent MF has excellent diffusivity and thermal stability, and it can make dyes bright in color, high in color strength and even in coloring. Pull-off powder is added to the fluorescent dye as a penetrating agent and wetting agent, which can significantly reduce the surface tension of water, has excellent penetrat...

Embodiment 1

[0043] The fluorescent dye provided in the embodiment of the present invention, in parts by weight, includes: 1610 parts of acid green, 5 parts of sodium polymethylnaphthalene sulfonate, 5 parts of sodium xylene sulfonate, 1 part of diffusing agent MF, and 5 parts of pull-away powder .

[0044] Preparation

[0045] S11: Add 1610 parts of acid green into the mixing kettle;

[0046] S12: Make the temperature reach 10°C, add 5 parts of sodium polymethylnaphthalene sulfonate, 5 parts of sodium xylene sulfonate, 1 part of diffusing agent MF, 5 parts of pull-off powder and a certain amount of water;

[0047] S13: Stir the dye and the mixing aid in the mixing tank for 2 hours to fully mix the dye and the mixing aid; obtain a uniform dye solution.

Embodiment 2

[0049] The fluorescent dyes provided by the embodiments of the present invention, in parts by weight, include: 40 parts of acid red 52, 28 parts of acid yellow 184, 5 parts of sodium polymethylnaphthalene sulfonate, 5 parts of sodium xylene sulfonate, diffusing agent MF2 2 parts, 2 parts of sodium lignosulfonate, 5 parts of pulling powder, and 5 parts of organosilicon brightening agent.

[0050] Preparation

[0051] S21: Add 40 parts of acid red 52 and 28 parts of acid yellow 184 into the mixing kettle;

[0052] S22: Bring the temperature to 30°C, add 5 parts of sodium polymethylnaphthalene sulfonate, 5 parts of sodium xylene sulfonate, 2 parts of diffusing agent MF, 5 parts of pull-off powder, 2 parts of sodium lignosulfonate, and organic silicon Brightening agent 5 parts and a certain amount of water;

[0053] S23: Stir the dye and the mixing aid in the mixing tank for 8 hours to fully mix the dye and the mixing aid; obtain a uniform dye solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com