Textile machine textile dust collection device

A technology of machine spinning dust and collecting device, applied in the textile field, can solve the problems of generating dust, affecting the cleanliness of the workshop, and affecting the health of the staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

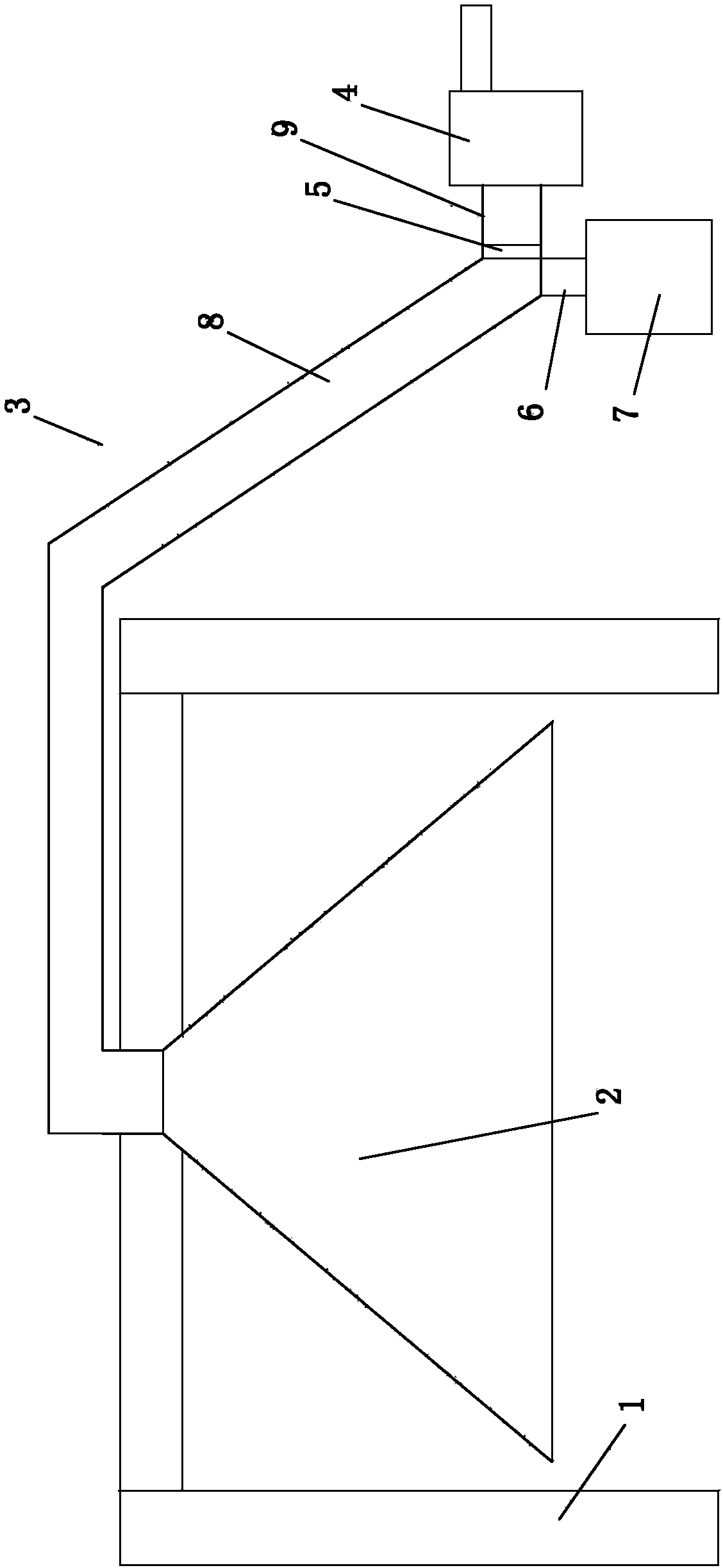

[0010] see figure 1 , textile machine textile dust collection device, including a support 1 installed on the textile equipment, a collection bucket 2 with a conical cross section is arranged on the support, a collection pipe 3 communicating with the collection chamber of the collection bucket is provided on the collection bucket, and the collection The pipe is connected to the input end of a blower fan 4, and a filter screen 5 is arranged in the collection pipe, and the collection pipe at the front end of the filter screen is connected with a dust outlet pipe 6, and the outlet end of the dust outlet pipe is in a collection bag 7. The collecting pipe includes an inclined pipe 8 and a straight pipe 9 communicating with the inclined pipe, and the filter screen 5 is located at the joint between the straight pipe and the inclined pipe. The inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com