Polyurethane foam plastic and preparation method thereof

A foamed plastic and polyurethane technology, applied in the field of polyurethane foamed plastic and its preparation, can solve the problems of not using methyl formate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

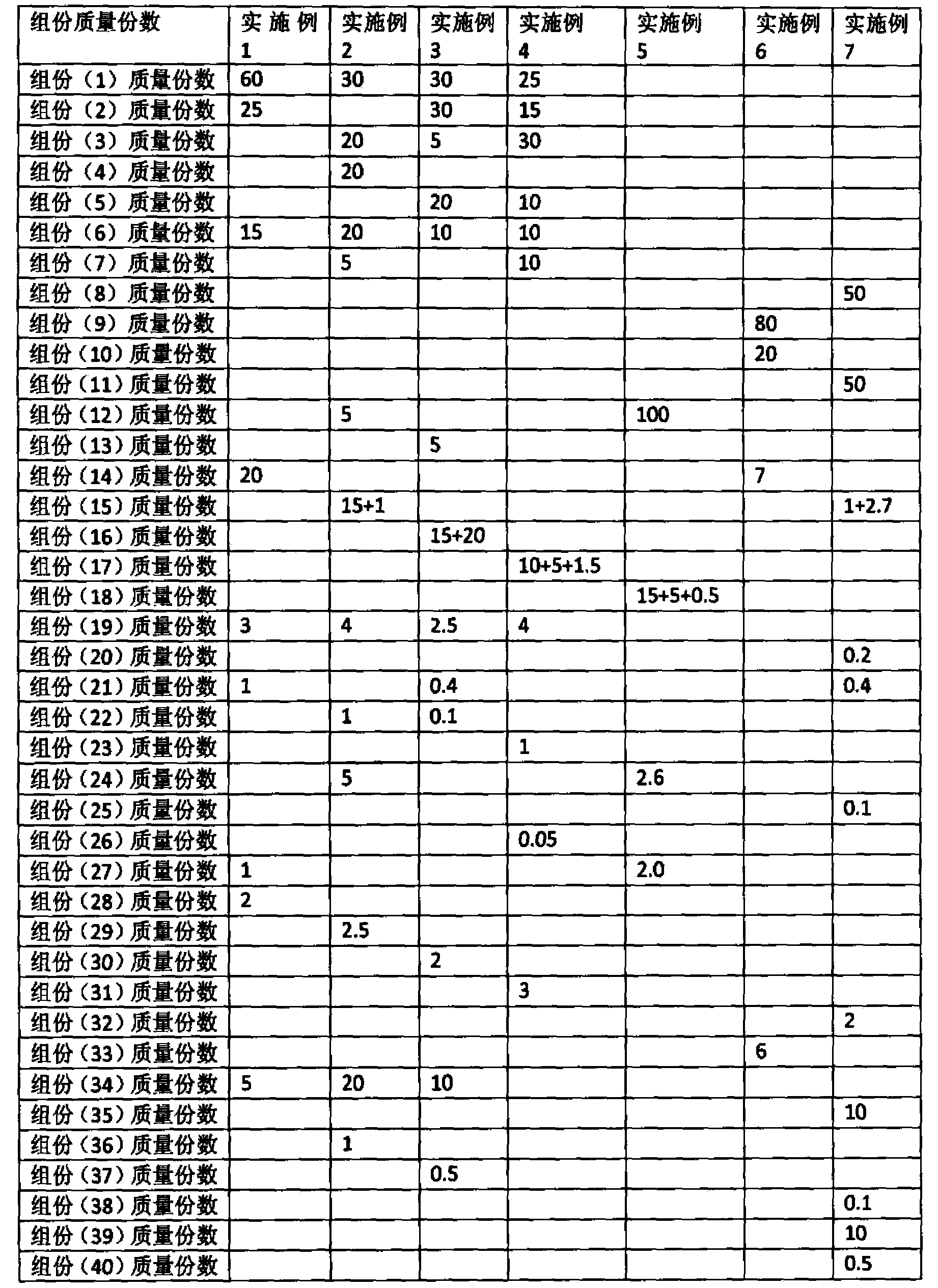

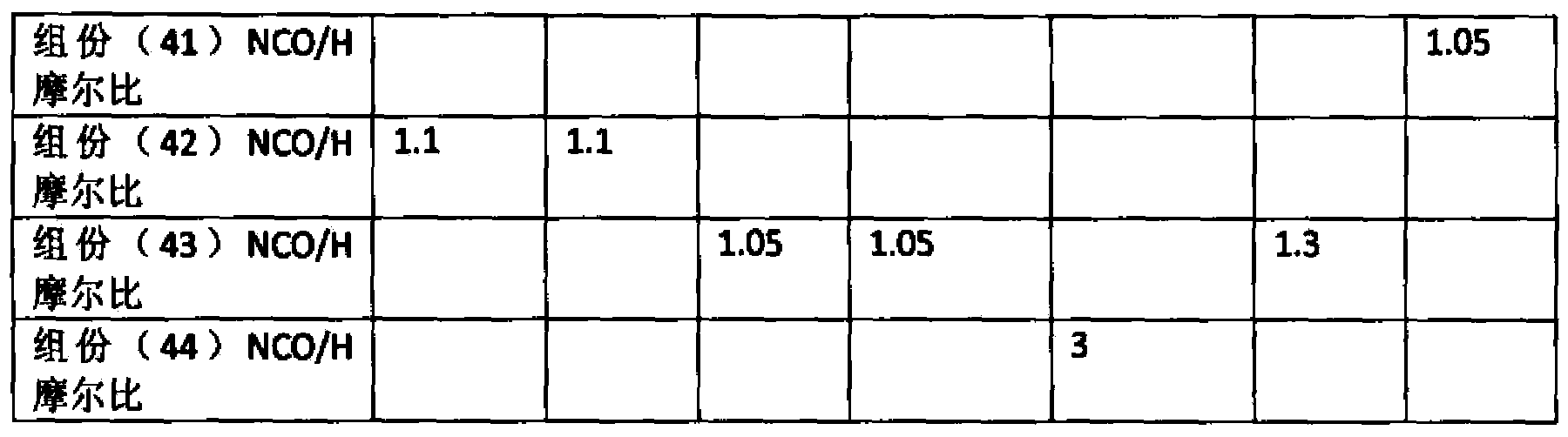

Embodiment 1-7

[0030] The raw material that embodiment formula uses is as follows:

[0031] 1. Polyol component

[0032] Component (1): starting with sucrose and glycerin, polyether polyol with a hydroxyl value of 400-500 mgKOH / g;

[0033] Component (2): a polyether polyol with a hydroxyl value of 350-400 mgKOH / g, starting with sorbitol and glycerin;

[0034] Component (3): starting with sorbitol and glycerin, polyether polyol with a hydroxyl value of 450-530 mgKOH / g;

[0035] Component (4): polyether polyol with ethylenediamine as the initiator and a hydroxyl value of 740-800 mgKOH / g;

[0036] Component (5): a polyether polyol with a hydroxyl value of 380-450 mgKOH / g starting with diammonium toluene;

[0037]Component (6): starting with sucrose, glycerin, and vegetable oil, polyether polyol with a hydroxyl value of 410-470 mgKOH / g;

[0038] Component (7): Polyether synthesized from phosphorus oxychloride, glycerin, antimony trichloride, propylene oxide, and epichlorohydrin, with a hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com