Rotating disc type multi-scale metering device

A metering device, turntable-type technology, applied in the field of turntable-type multi-scale metering device, can solve the problems of low weighing and metering efficiency, metering and packing can not be carried out at the same time, to achieve the effect of increasing the speed of metering and packing, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

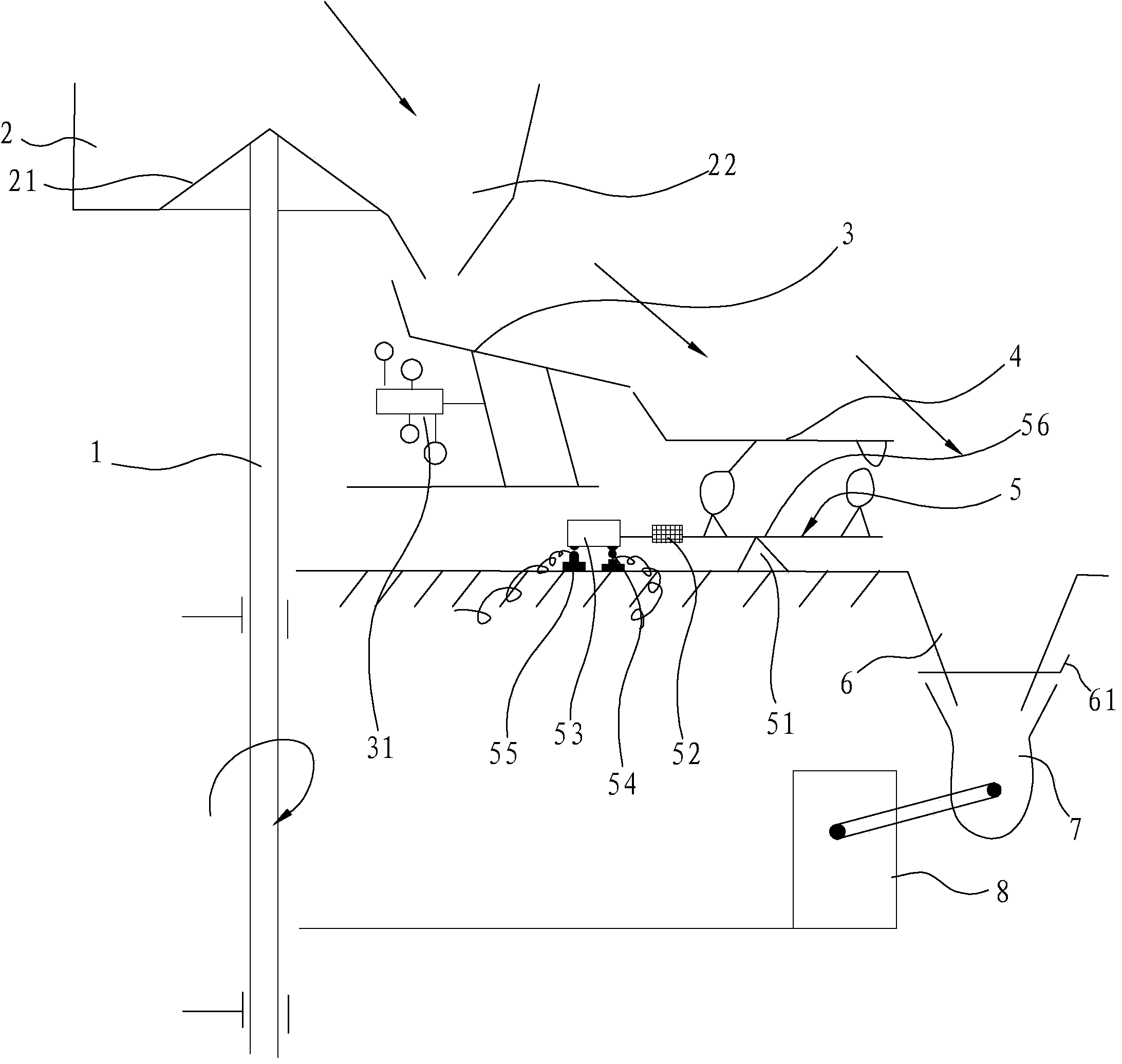

[0012] like figure 1 As shown, the rotary disc type multi-scale metering device in this implementation includes a feeder 2, a rotating shaft 1, a container 7, a reclaimer and several scale metering devices and the like.

[0013] Wherein, there is a discharge port 22 below the container 2, and the rotating shaft 1 is arranged at the center of the container 2 to drive the container 2 to rotate. It is arranged below the stocker 2, and the number of several weighing devices can be configured as required, but limited by the size of the stocker 2.

[0014] Each scale metering device is now described:

[0015] Each scale metering device includes a vibration feeder 3 , a tipping bucket type dipping device 4 , a balance 5 , and a filling hopper 6 . Wherein, the feed port of the vibrating feeder 3 corresponds to the discharge port 22 of the container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com