Double guide positioning device for mounting auxiliary frame

A technology of positioning device and sub-frame, which is applied in vehicle parts, transportation and packaging, substructure and other directions, can solve the problems of low work efficiency and inconvenient installation, and achieves reduction of non-value-added adjustment time, shortening of extension length, The effect of reducing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

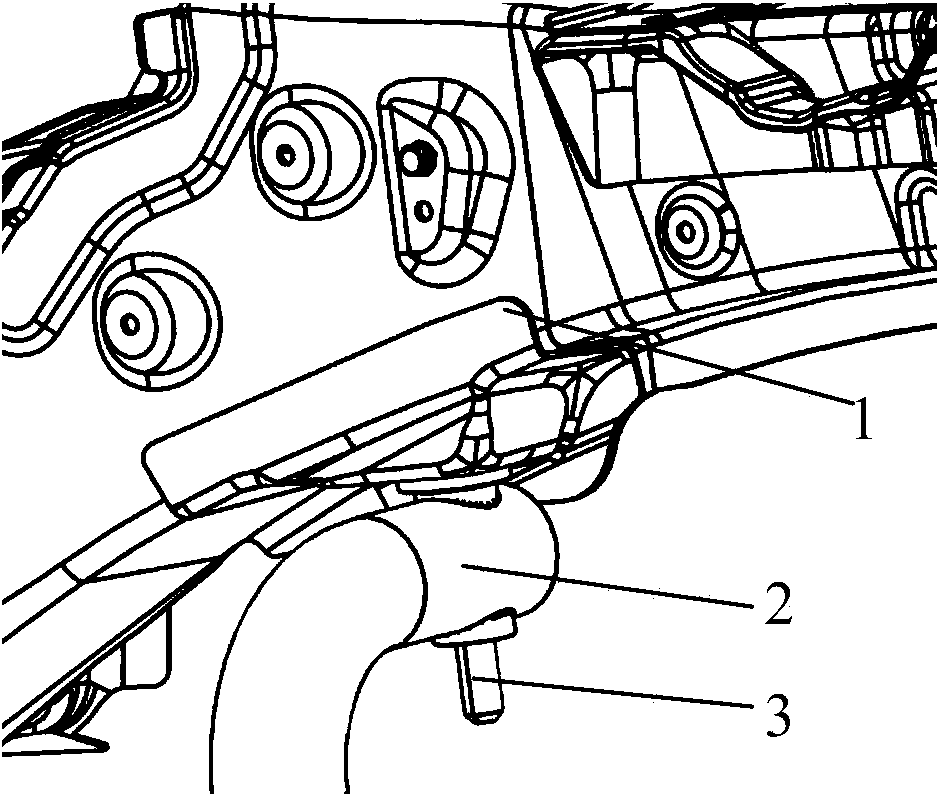

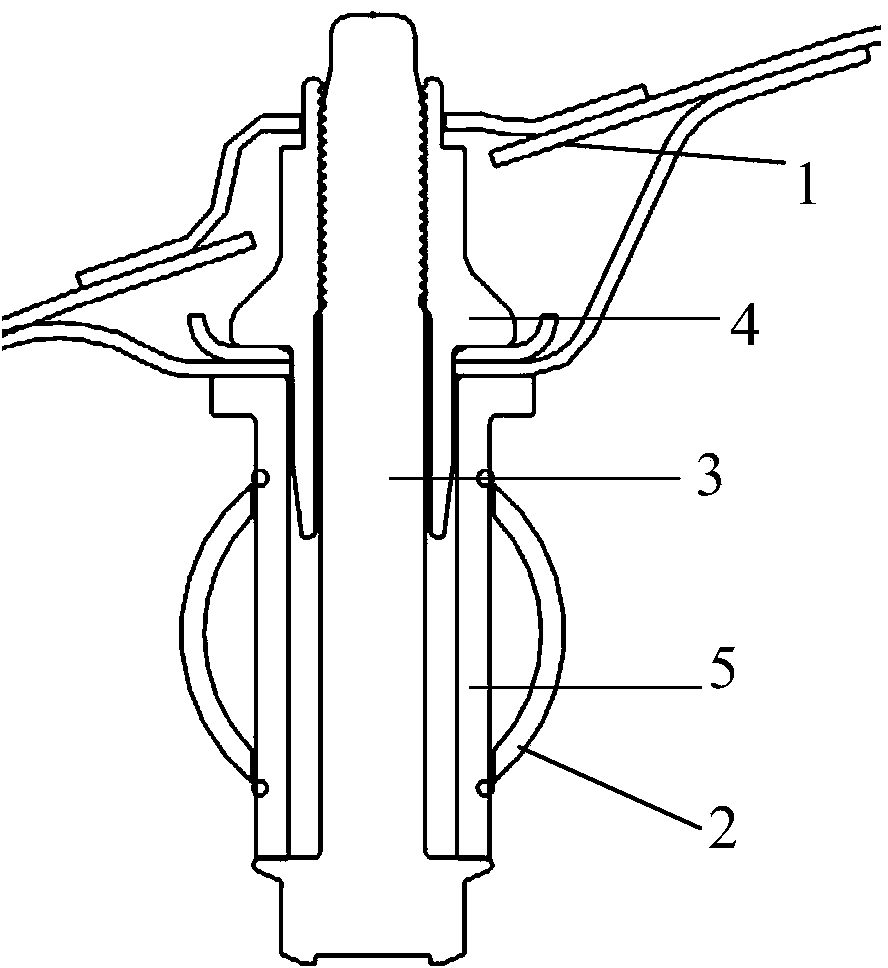

[0016] A double-guided positioning device installed on a sub-frame, comprising a sub-frame, a front frame 1, bolts 3 and nuts 4, the sub-frame is provided with a connecting pipe 2, and the connecting end of the connecting pipe 2 is bent horizontally, the Bolts 3 vertically pass through the front frame 1 and the connecting pipe 2 , and the bolts 3 cooperate with the nuts 4 to connect and fix the front frame 1 and the connecting pipe 2 .

[0017] The double guide positioning device installed on the sub-frame also includes a sub-frame sleeve 5, the sub-frame sleeve 5 passes through the connecting pipe 2, and the upper end of the sub-frame sleeve 5 is also provided with a boss, The bolt 3 passes through the subframe sleeve 5 .

[0018] The nut 4 is also provided with a guide sleeve.

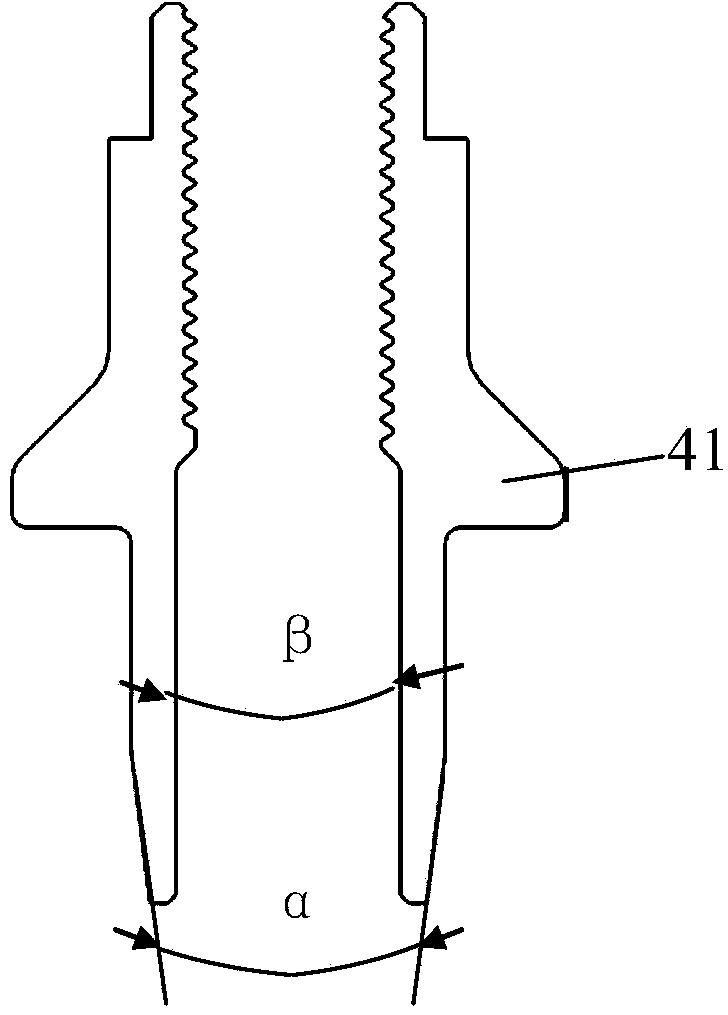

[0019] The nut 4 is also provided with a fixing protrusion 41 , and the plane end of the fixing protrusion contacts the front frame 1 .

[0020] The guide sleeve is also provided with an outer guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com