Embedded numerical-control printing pressing force adjustment and clearance tolerance elimination device

An embedded numerical control and gap elimination technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of inconvenient adjustment of vertical and horizontal and angle adjustment, large vibration, and processing accuracy error, etc., to achieve convenience Replacement of rubber and maintenance, small vibration, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

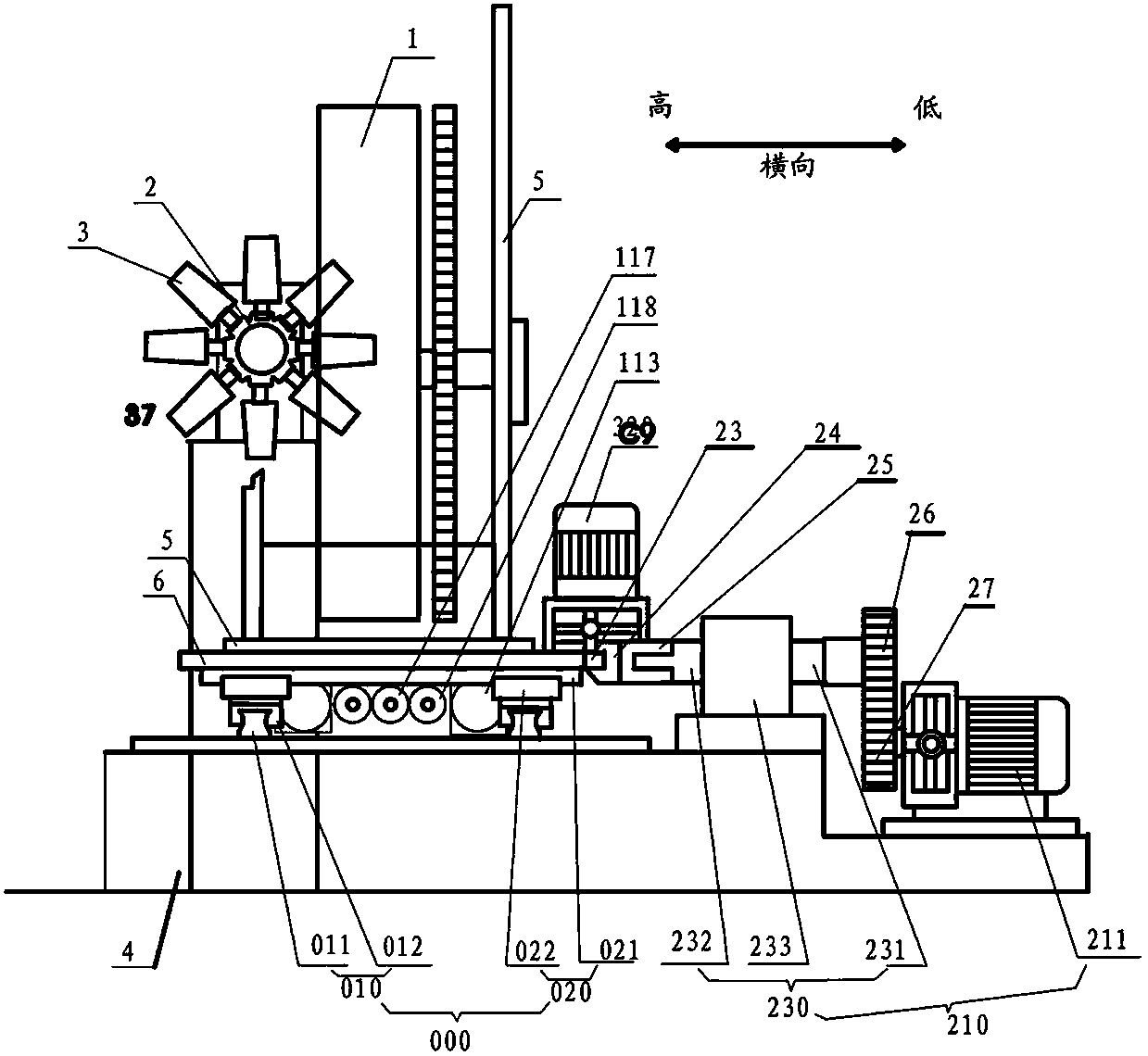

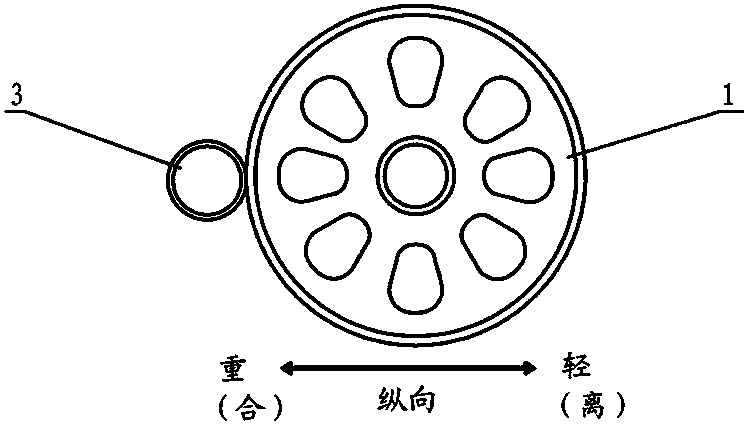

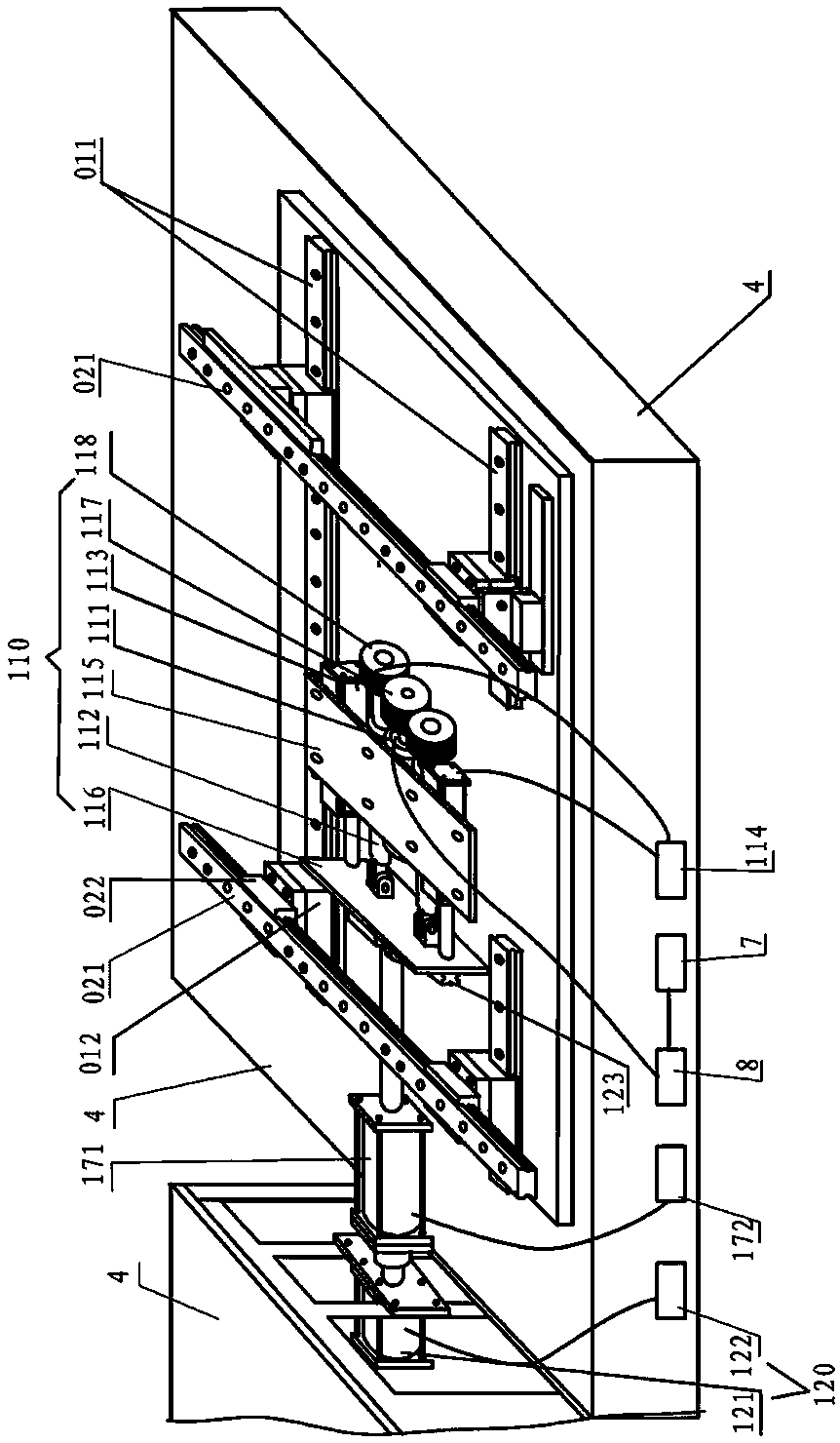

[0035] see figure 1 , image 3 , Figure 7 As shown, the displacement printing pressing force and gap tolerance elimination device of the curved surface printing machine of the preferred embodiment of the present invention includes a printing device with an eight-station stepping indexing turntable 2 and a mold handle 3 arranged on a base 4 And be located at the printing main frame that has transfer printing big drum wheel 1 on the main frame support 5. The base 4 is provided with a two-dimensional orthogonal sliding seat, and the main frame 5 is arranged on the two-dimensional orthogonal sliding seat through the main base plate 6; in order to solve the tolerance gap due to the longitudinal moving device in high-speed printing And the vibration that produces, also be provided with the vertically moving device 110 that eliminates gap, the embedded controller 8 with touch screen 7 that controls above-mentioned vertically moving device 110 that eliminates gap, the vertically mo...

Embodiment 2

[0042] Such as Figure 4 , Figure 5 , Figure 7 Shown is a schematic diagram of Embodiment 2 of the high-speed curved surface printing machine of the present invention. The difference between this embodiment and Embodiment 1 is: the large-scale clutch device is connected to the connecting plate 116 through the clutch cylinder 121; the large-scale clutch device also includes a large-scale clutch cylinder 171, a large-scale clutch solenoid valve 172, the cylinder block of the large-scale clutch cylinder 171 is fixed to the base 4 through the hinge support 173, and the function of the hinge support 173 is to make the large-scale clutch cylinder properly rotate around the hinge support 173. To adjust the height error between the clutch cylinder 121. The cylinder shaft of the large-scale clutch cylinder 171 is connected to the cylinder body of the clutch cylinder 121, and the cylinder shaft of the clutch cylinder 121 is connected to the connecting plate 116 through the plug con...

Embodiment 3

[0048] Image 6 , Figure 7 It is another embodiment of the longitudinal movement device for eliminating the tolerance gap in the displacement printing pressing force and gap tolerance device of the curved surface printing machine of the present invention. In this example:

[0049] The longitudinal pressing force adjustment device 130 includes a longitudinal movement motor 131, two longitudinal screw nut tube transmission devices 132 symmetrically arranged on both sides of the longitudinal movement motor 131, and two longitudinal screw nut tube transmission devices 132 arranged outside or below the two longitudinal screw nut tube transmission devices respectively. The longitudinal gap elimination cylinder 133, the gap elimination electromagnetic valve 134 and the fixed plate 135 connecting the two longitudinal gap elimination cylinders 133, the longitudinal movement motor 131 and the two longitudinal gap elimination cylinders 133 are fixed on the top of the fixed plate 135 O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com