Coiling block rubber sleeve assembling and disassembling tool and assembling and disassembling method

A technology for loading and unloading tools and rubber sleeves, which is applied in the field of unloading tools for reel rubber sleeves and reel rubber sleeves. It can solve the problems of high labor intensity, uneven force on rubber sleeves, and affecting the installation of rubber sleeves, and achieve simplified loading and unloading. Low operating and production costs, and the effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

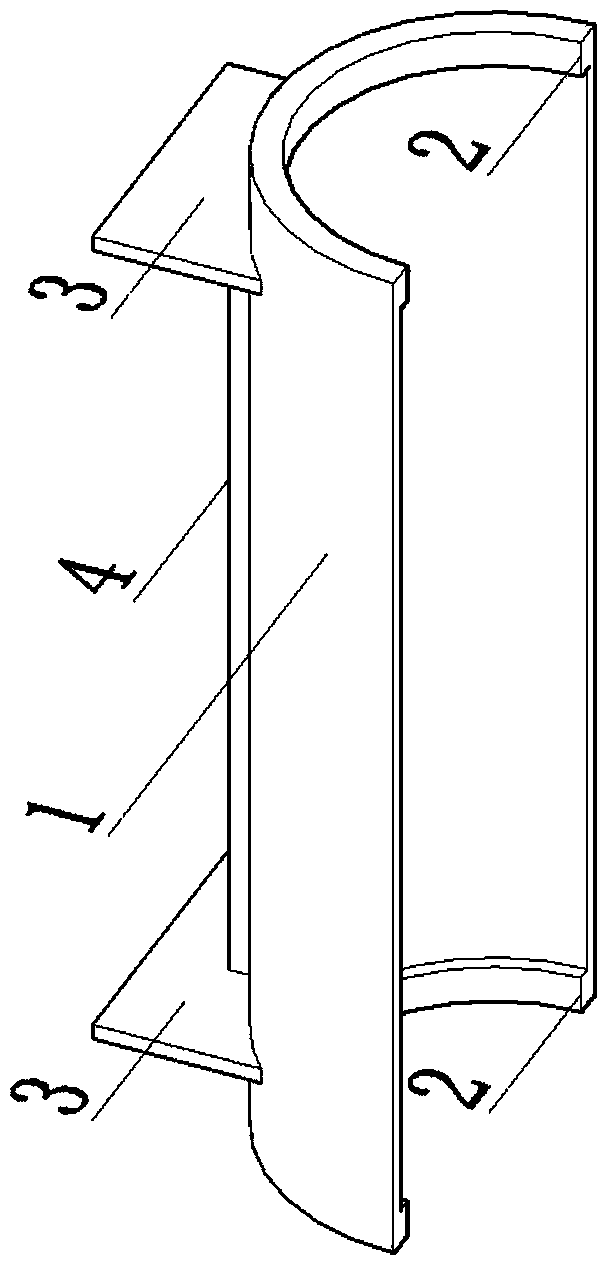

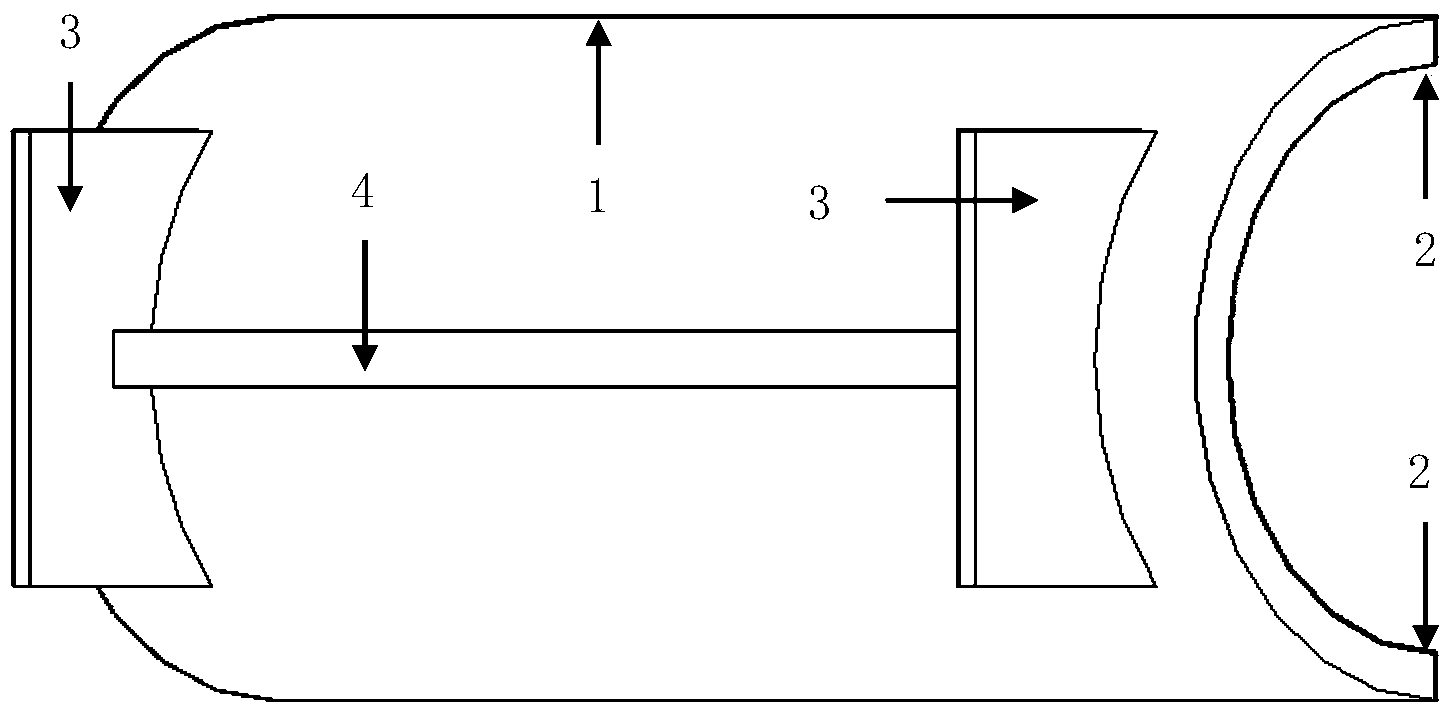

[0031] Such as Figure 1 to Figure 3 As shown, the "reel rubber sleeve removal tool" of the present invention includes a tank body 1, the cross section of which is semicircular, and the inner diameter of the cross-sectional ring of the tank body 1 is equal to the outer diameter of the cross-sectional ring of the rubber sleeve 7 The two ends of the tank body 1 are respectively provided with a rubber sleeve stop ring 2, and the thickness of the two rubber sleeve stop rings 2 is equal, which is half of the thickness of the rubber sleeve 7, such as Figure 4 with Figure 5 shown.

[0032] Such as Figure 4 with Figure 5 As shown, the "reel rubber set removal tool" is used in conjunction with the steel coil trolley, and the tank body 1 is installed on the car body saddle 5 of the steel coil trolley through a fixing mechanism. Specifically, two baffles 3 are provided at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com