Automatic length fixing floating support device for machining crossover coupling

A floating support and automatic length-fixing technology, which is applied in positioning devices, clamping devices, thread cutting devices, etc., can solve the problems of high scrap rate, low processing accuracy, and low efficiency, and achieve high production efficiency and satisfactory processing accuracy. The effect of precision problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

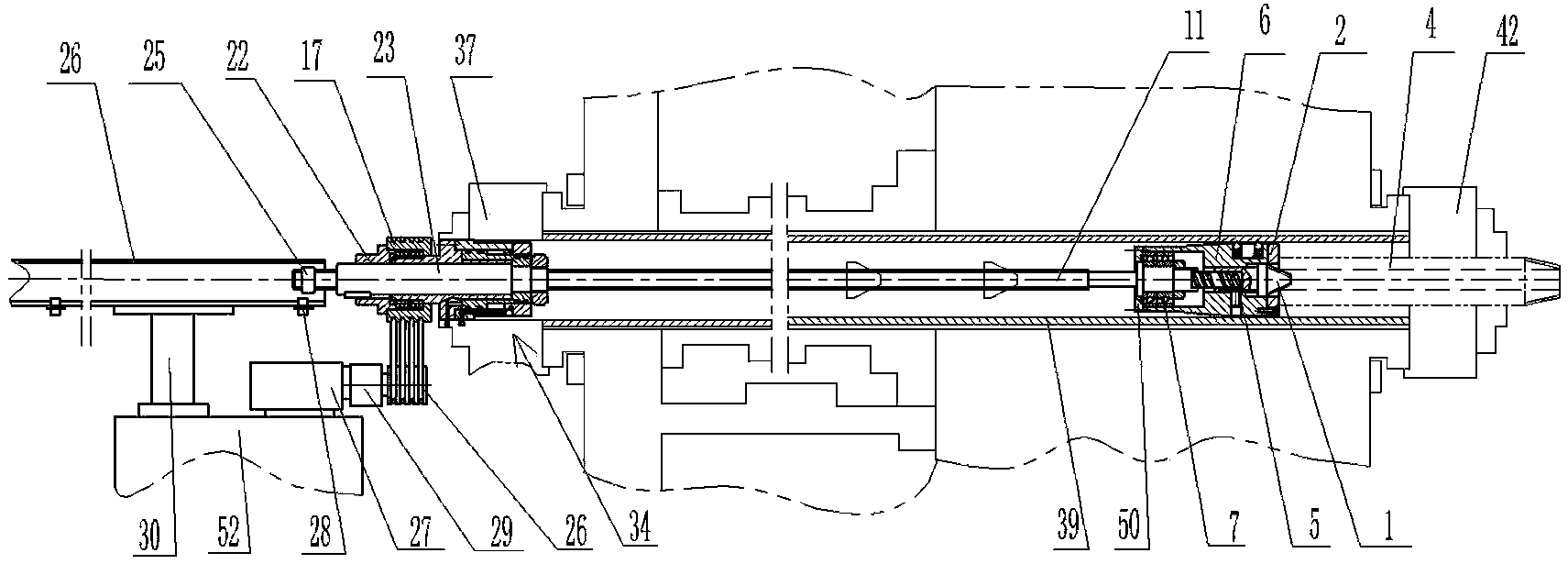

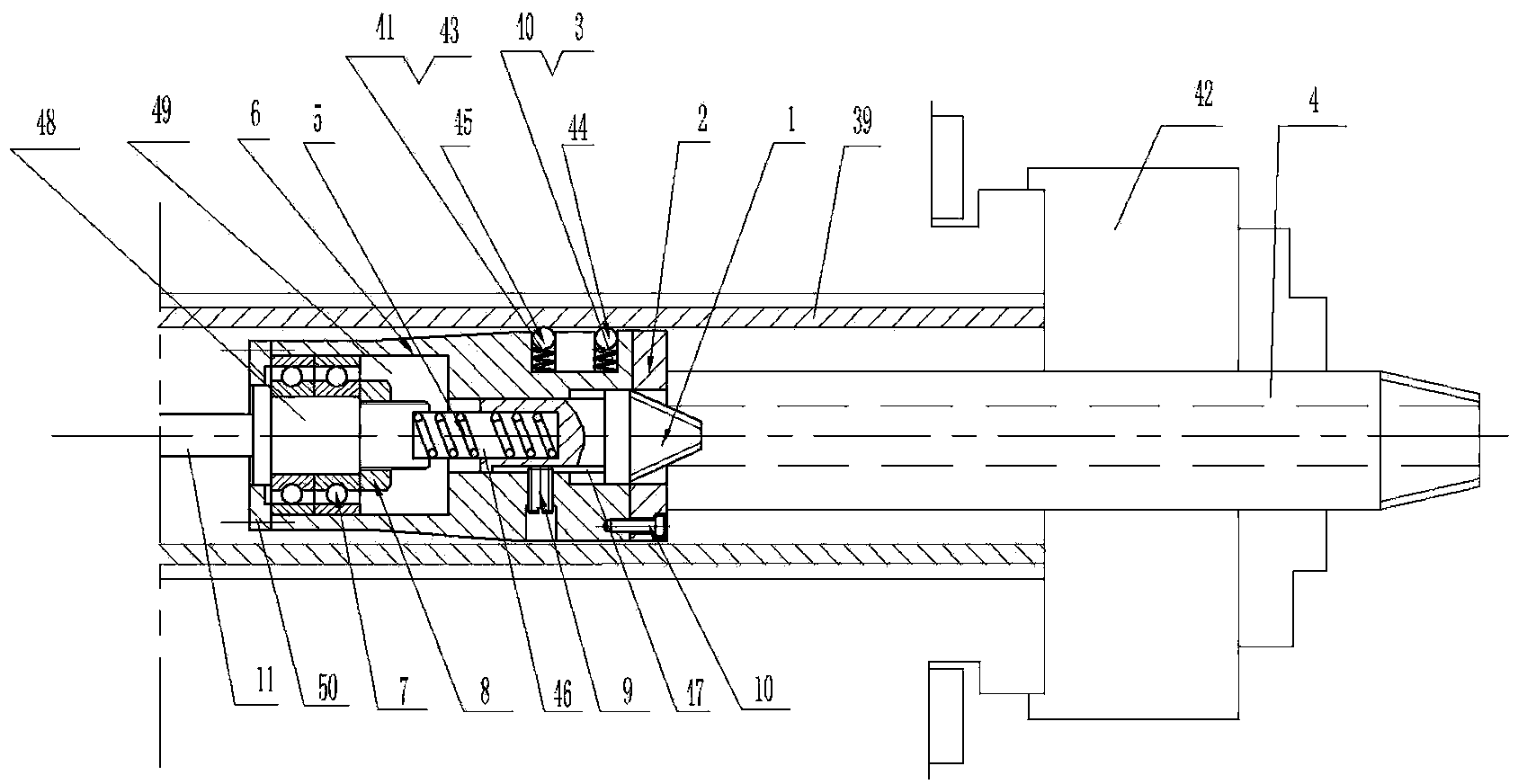

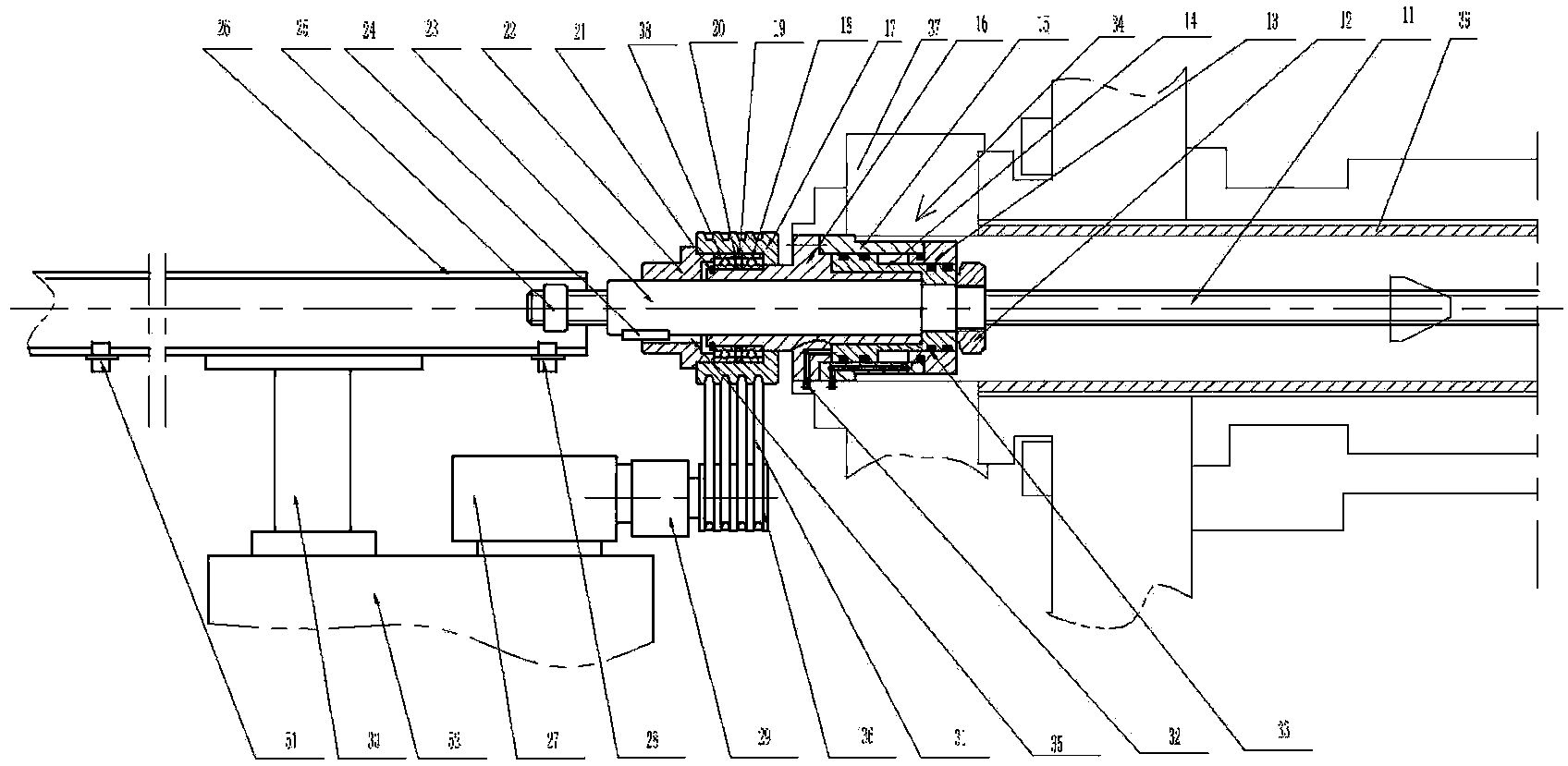

[0020] An automatic fixed-length floating support device for processing conversion joints, including a floating support mechanism, a lead screw 11, a screw nut 23, a screw axial movement drive mechanism, a screw nut rotation drive mechanism and a switch bracket assembly, characterized in that:

[0021] The floating support mechanism is installed in the front part of the main shaft drawing tube 39, and the floating support mechanism includes the top 1, the positioning end cover 2 and the guide sleeve 6. The positioning end cover 2 is fixedly connected with the guide sleeve 6 through a plurality of bolts 10 . Three first cylindrical holes 40 and three second cylindrical holes 41 are respectively and equidistantly formed on the outer surface of the front end of the guide sleeve 6 at two locations. The first springs 3 are respectively installed in the three first cylindrical holes 40 , and the second springs 43 are respectively installed in the three second cylindrical holes 41 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com