Coating material dispersion machine

A technology for dispersing machines and coatings, applied in mixers, mixer accessories, mixers with rotary stirring devices, etc., can solve the problems of large particles and low degree of fineness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

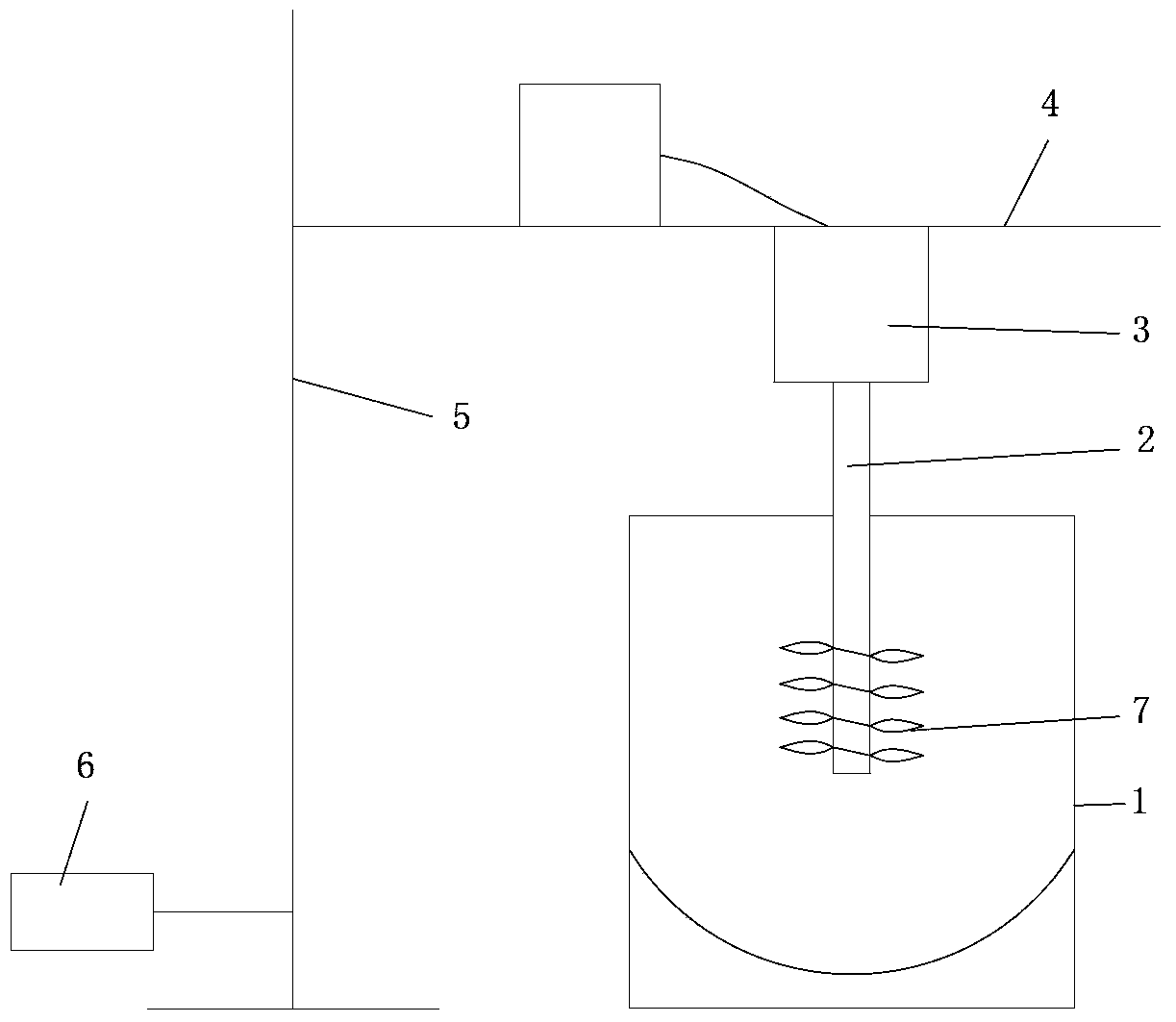

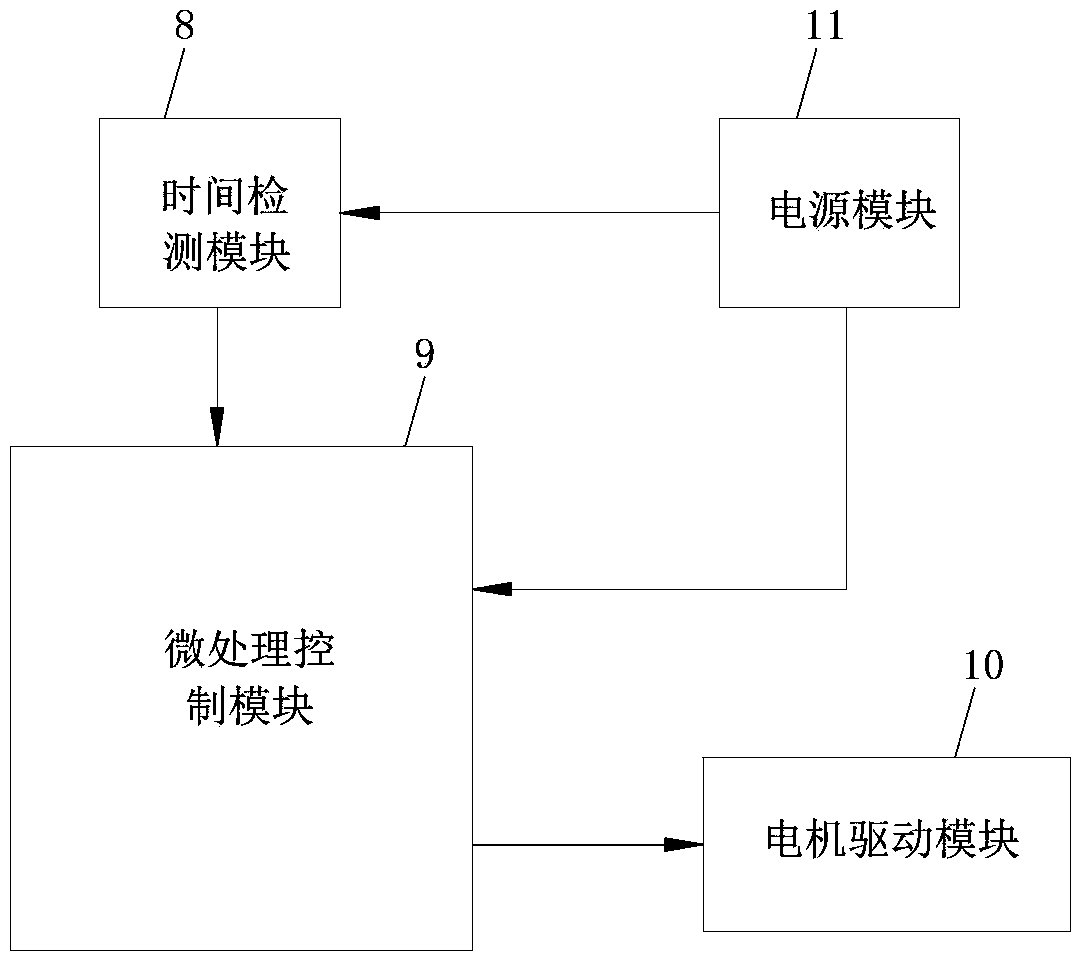

[0013] refer to figure 1 , a paint dispersing machine of the present invention includes a stirring container 1, a rotating shaft 2, a rotating motor 3, a mounting plate 4, a lifting rod 5, and a vibration motor 6. The inner bottom wall surface of the stirring container 1 is a hemispherical surface. The rotating motor 2 is fixed on one end of the mounting plate 4 , and the top of the elevating rod 5 is fixed on the other end of the mounting plate 4 ; the lower end of the rotating motor 3 is connected with the rotating shaft 3 . The bottom of the rotating shaft 2 is provided with a helical blade 7 . The lifting rod 5 is connected with the vibrating motor 6, and the lower part of the rotating shaft 2 is located in the stirring container 1. Also comprise a motor control device, this motor control device comprises time detection module 8, microprocessing control module 9, motor drive module 10 and power supply module 11, the output end of time detection module 8 is electrically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com