Fruit powder and production method thereof

A fruit powder and apple technology, applied in the field of beverages, can solve the problems of not being able to carry it around, side effects, and not being able to drink at any time, and achieve the effects of good taste, cough relief, and relief of dry throat pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

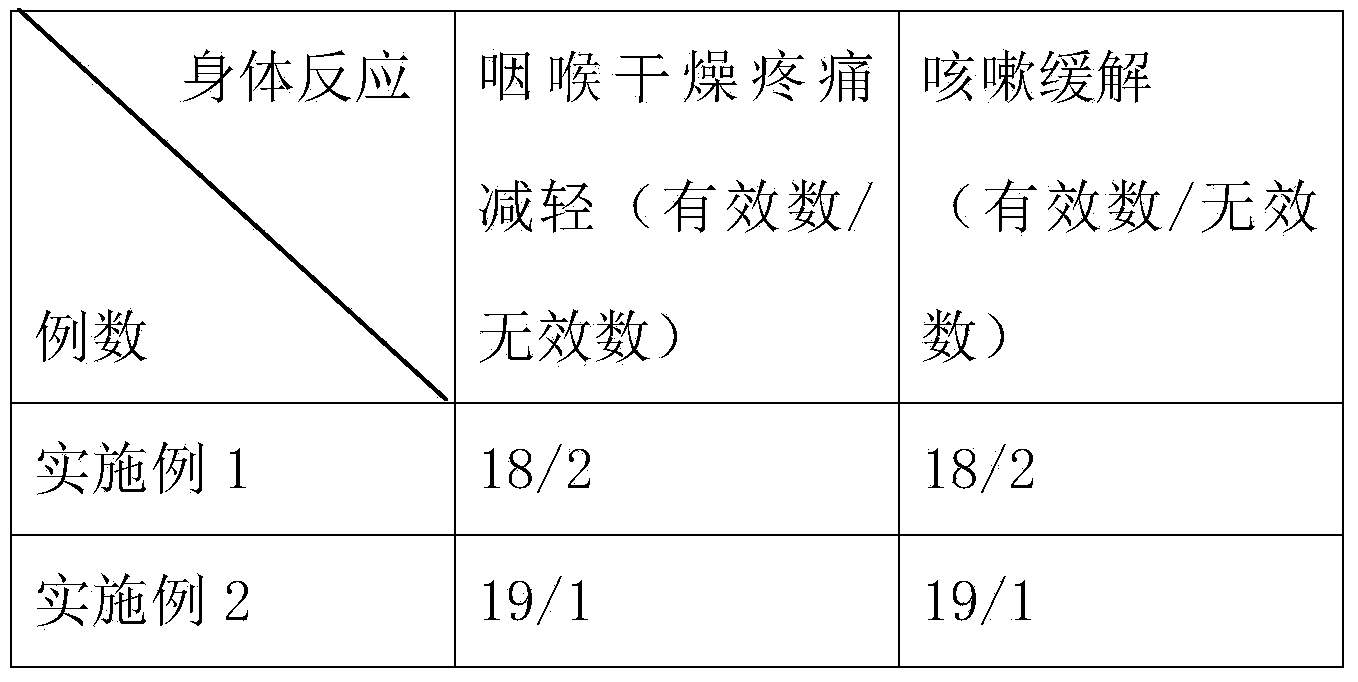

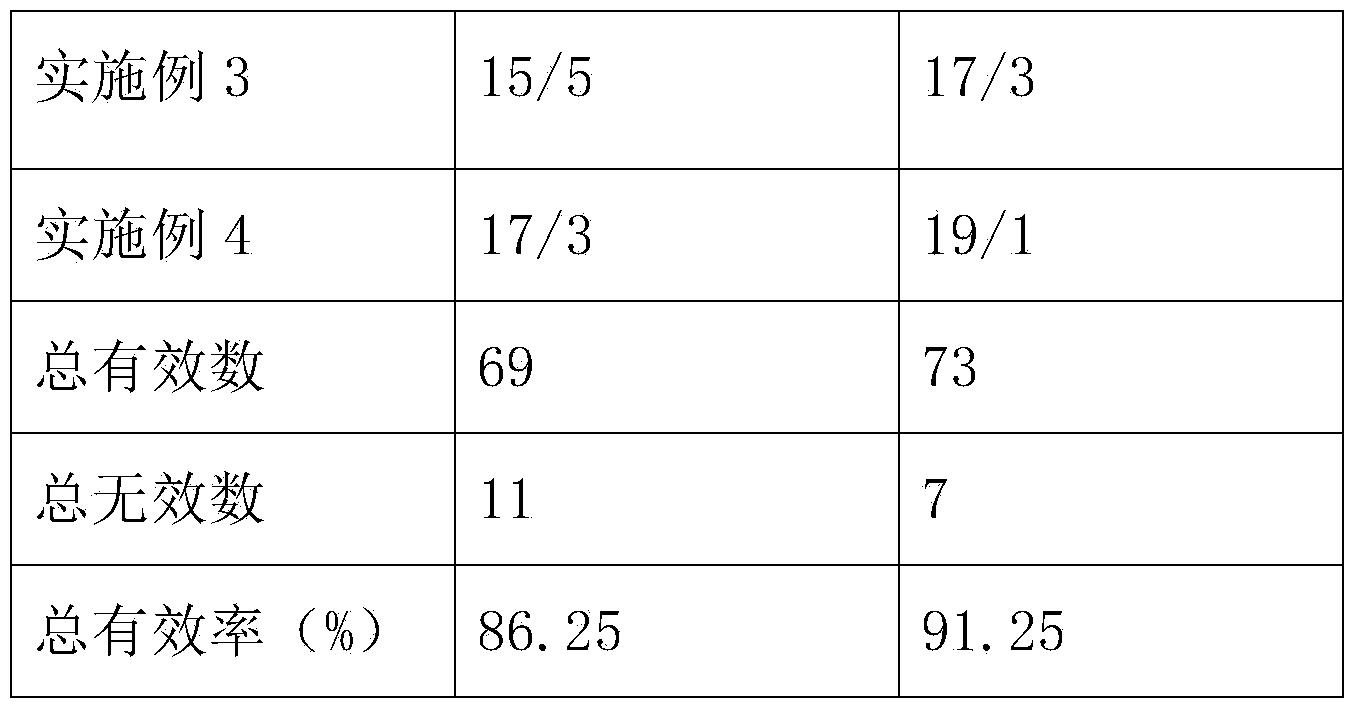

Examples

Embodiment 1

[0039] The fruit powder is made from the following raw materials in parts by weight: 10 parts of banana, 10 parts of jujube, 20 parts of apple, 5 parts of kiwi, 15 parts of mango, 20 parts of grape, 40 parts of olive, 5 parts of lemon, 10 parts of konjac powder, Rock sugar 4 parts.

[0040] 1. Weigh the raw materials according to the above weight ratio and wash them respectively. Peel the bananas and kiwis, peel the apples, mangoes, and grapes, remove the pits from the jujubes and olives, and put them into a slicer to slice respectively to obtain mixed sliced ingredients;

[0041] The thickness of each slice raw material is 5mm;

[0042] 2. Put the mixed slicing raw materials into a food dryer, and dry them at a temperature of 70°C for 1.5 hours to obtain the dried mixed slicing raw materials;

[0043] 3. Put the dried mixed and sliced raw materials into a powder machine for grinding for 1 hour and then pass through a 100-mesh sieve to obtain a primary fruit mixture;

...

Embodiment 2

[0047] The fruit powder is made from the following raw materials in parts by weight: 20 parts of bananas, 15 parts of jujubes, 30 parts of apples, 10 parts of kiwis, 17 parts of mangoes, 23 parts of grapes, 50 parts of olives, 8 parts of lemons, 15 parts of konjac flour, 9 parts rock sugar.

[0048] 1. Weigh the raw materials according to the above weight ratio and wash them respectively. Peel the bananas and kiwis, peel the apples, mangoes, and grapes, remove the pits from the jujubes and olives, and put them into a slicer to slice respectively to obtain mixed sliced ingredients;

[0049] The thickness of each slice raw material is 5mm;

[0050] 2. Put the mixed slicing raw materials into a food dryer, and dry them at a temperature of 70°C for 1.5 hours to obtain the dried mixed slicing raw materials;

[0051]3. Put the dried mixed and sliced raw materials into a powder machine for grinding for 1 hour and then pass through a 100-mesh sieve to obtain a primary fruit mixt...

Embodiment 3

[0055] The fruit powder is made from the following raw materials in parts by weight: 30 parts of banana, 20 parts of jujube, 30 parts of apple, 15 parts of kiwi, 20 parts of mango, 25 parts of grape, 60 parts of olive, 10 parts of lemon, 20 parts of konjac powder, 10 parts rock sugar.

[0056] 1. Weigh the raw materials according to the above weight ratio and wash them respectively. Peel the bananas and kiwis, peel the apples, mangoes, and grapes, remove the pits from the jujubes and olives, and put them into a slicer to slice respectively to obtain mixed sliced ingredients;

[0057] The thickness of each slice raw material is 5mm;

[0058] 2. Put the mixed slicing raw materials into a food dryer, and dry them at a temperature of 70°C for 1.5 hours to obtain the dried mixed slicing raw materials;

[0059] 3. Put the dried mixed and sliced raw materials into a powder machine for grinding for 1 hour and then pass through a 100-mesh sieve to obtain a primary fruit mixture; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com