Oxygen enrichment bottom blowing copper smelting process energy efficiency evaluation method based on process simulation

A technology of process simulation and energy efficiency, applied in the direction of program control, electrical program control, instruments, etc., can solve problems such as the inability to scientifically evaluate the operation level of equipment, tap energy-saving potentials to issue parameter optimization schemes, and lack theoretical basis, so as to tap energy-saving potentials , the effect of accurate energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

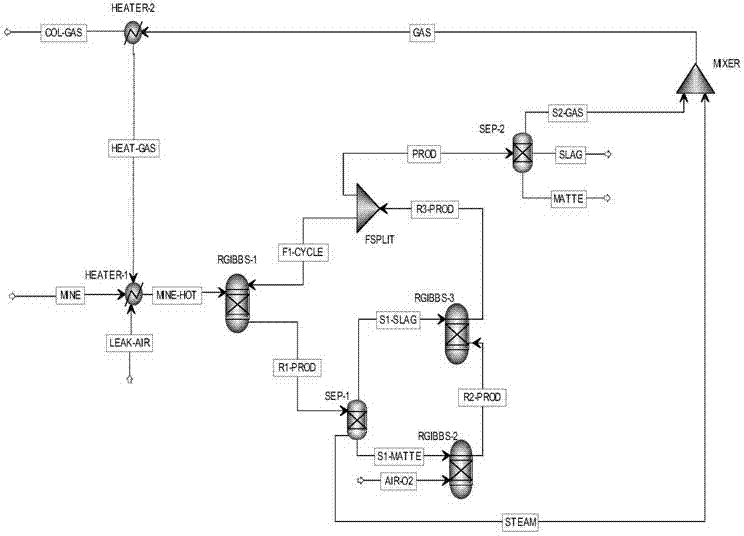

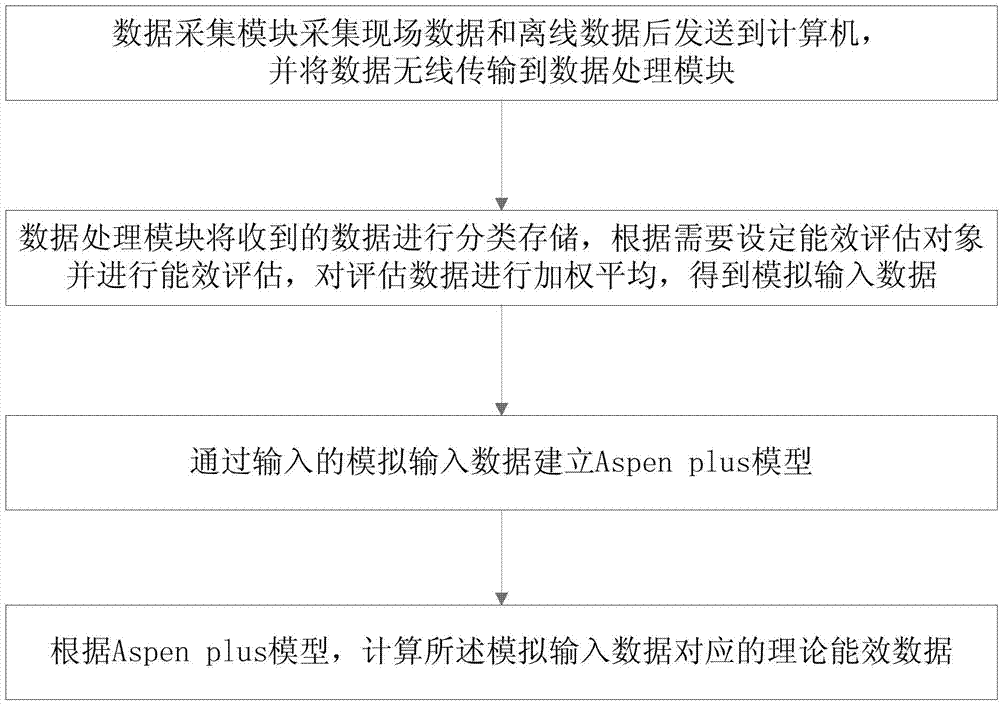

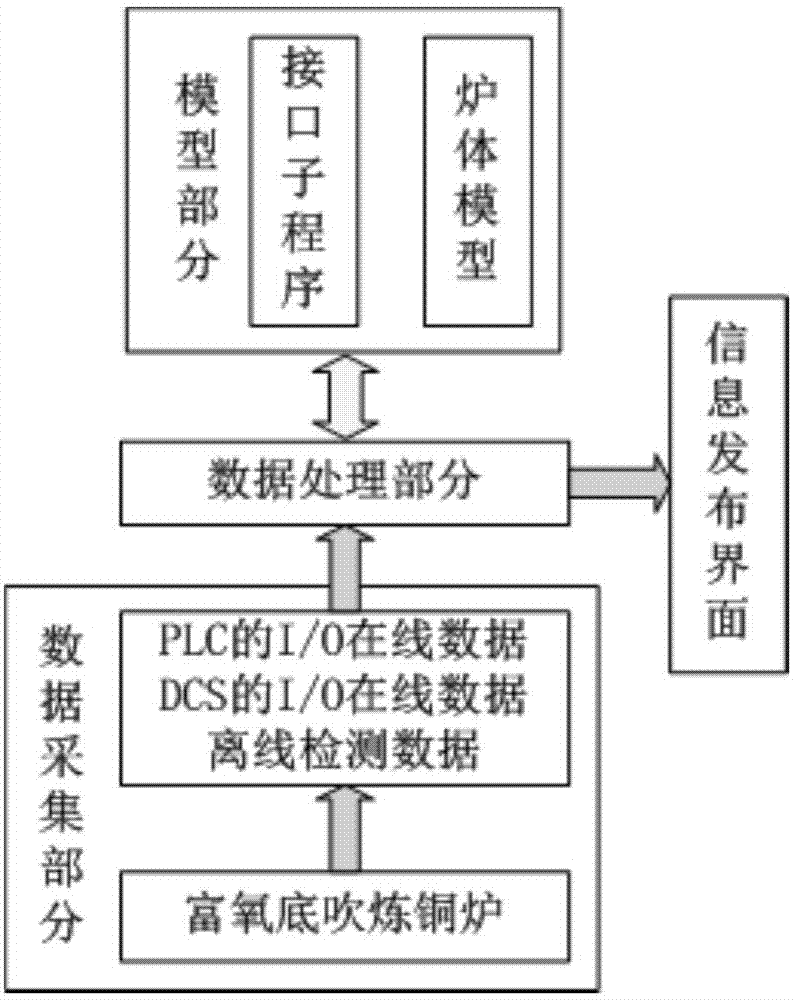

[0035] The overall structure of the process simulation-based energy efficiency evaluation method for oxygen-enriched bottom-blowing copper smelting process is as follows: figure 2 As shown, it includes: data acquisition and release part, data processing part, Aspen plus model part and information release interface of oxygen-enriched bottom blowing copper furnace, and the execution steps of the scheme are as follows figure 1 shown, including:

[0036] Step 1. The data acquisition part collects the online data collected by the on-site basic automation and control system, such as copper concentrate feed amount, copper concentrate composition analysis and oxygen-enriched flow rate, as well as the amount and composition of copper matte, slag and flue gas released The off-line data obtained by means of analysis such as weighing or testing is input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com