A glass detection device

A glass detection and reading device technology, applied in the detection field, can solve problems such as space occupation, inconvenient movement, and impact on logistics, and achieve the effects of improving utilization, ensuring cleanliness, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

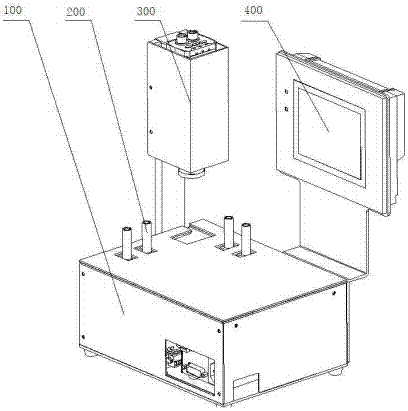

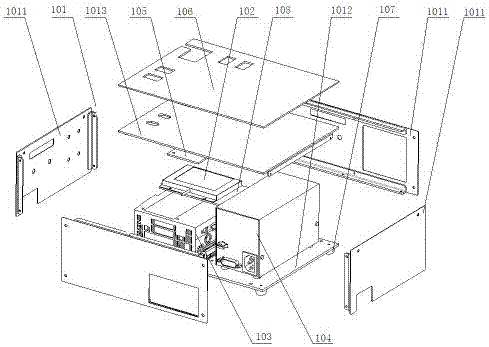

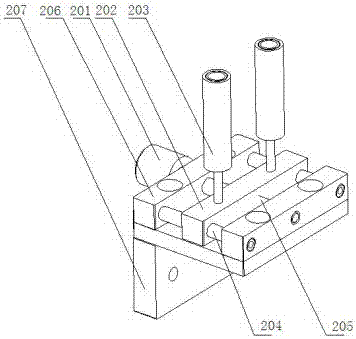

[0021] like Figure 1 to Figure 5 As shown, a glass detection device includes a main body device 100, a positioning adjustment device 200, a reading device 300 and an output device 400. The main body device 100 includes a chassis 101, a light source 102, a switching power supply 103 and a controller 104. The chassis 101 An antistatic rubber 106 is provided on the top, and the light of the light source 102 is emitted through the transparent plate 105; the positioning adjustment device 200 includes a knob 201, a slider 202, a positioning block 203 and a fixing block 206; the positioning block 203 is fixed on the sliding block 202 Above, the slider 202 is connected to the fixed block 206 through the guide post 204 and the lead screw 205, and one end of the lead screw 205 is fixedly connected to the knob 201; the reading device 300 includes a lens 301, and the lens 301 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com