A kind of multifunctional roller crushing experimental device and experimental method

A technology of experimental device and experimental method, which is applied in the field of machinery, can solve the problems of insufficient research on the parameters of crushing, and achieve the effects of convenient crushing experiment simulation, ingenious conception, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

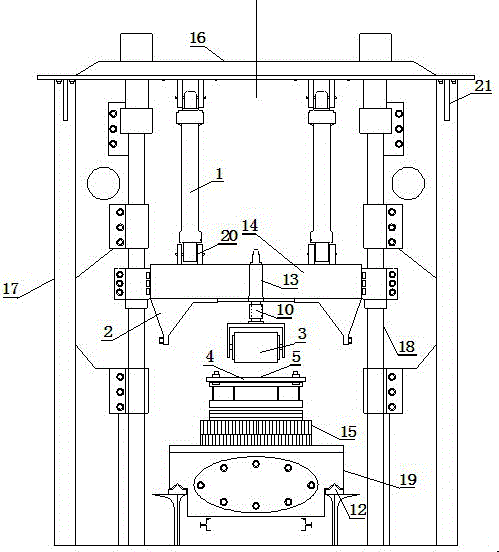

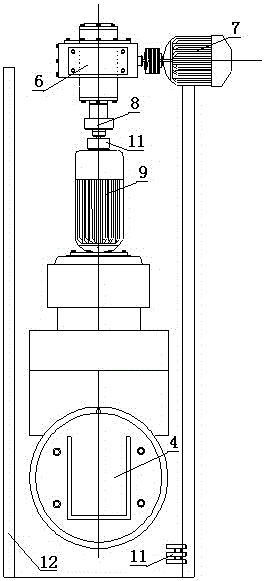

[0029] The structure of the multifunctional roller crushing experimental device of the present invention is as follows: figure 1 with figure 2 , comprising a bracket 17 and a top beam 16, a lifting platform 2 is installed under the top beam 16, the lifting platform 2 is fixed on the top beam 16 through a fixing block 14, a latch 20 and a hydraulic cylinder 1, and the lifting platform 2 is fixedly connected with the fixing block 14 , the fixed block 14 is connected with the hydraulic cylinder 1 through the bolt 20, the hydraulic cylinder 1 is controlled by the hydraulic control system, and the lifting frame 18 is installed on both sides of the lifting platform 2, and the lifting platform 2 can move up and down along the lifting frame 18; The suspension rod 13 is connected with the rotary roller 3, the upper end of the suspension rod 13 is fixed on the bottom of the lifting platform 2, and the lower end of the suspension rod 13 is threadedly connected with the rotary roller 3; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com