One-time over-temperature detecting method

An over-temperature detection, one-time technology, applied in thermometers, measuring devices, measuring heat, etc., can solve the problem of monitoring the smallest packaging, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

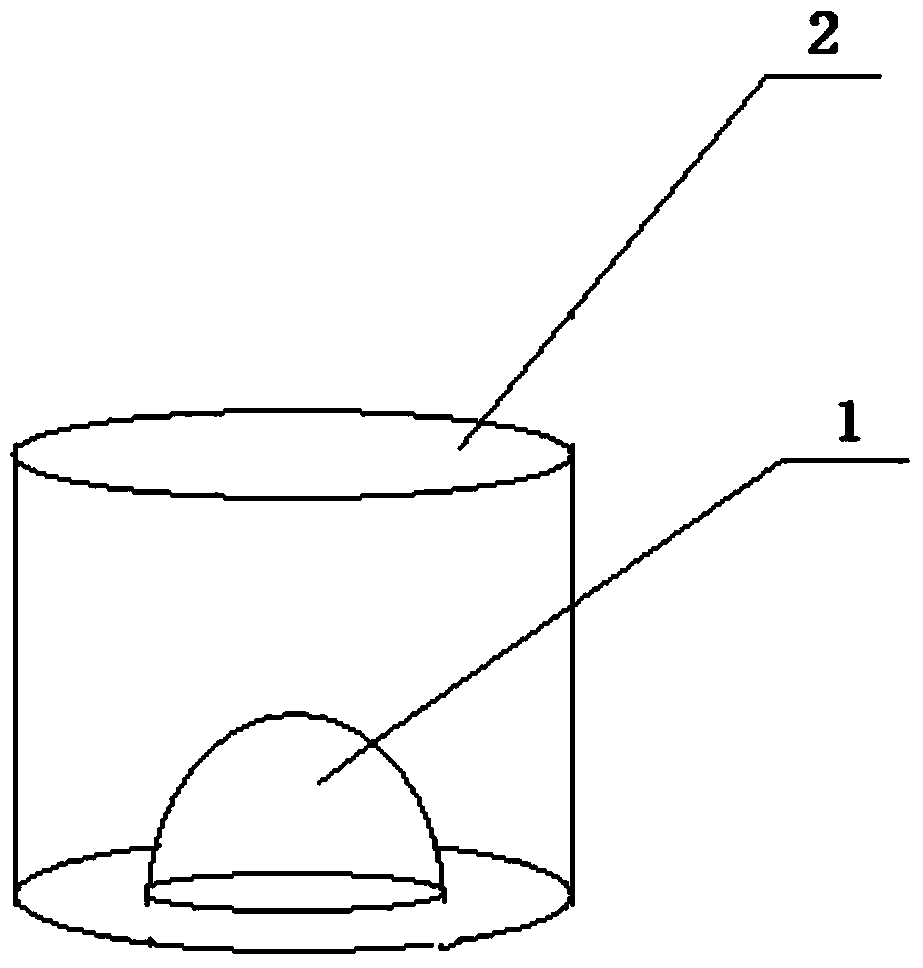

Image

Examples

Embodiment 1

[0026] In the one-time over-temperature detection method provided in this embodiment, filling material A and filling material B are respectively put into inner and outer airtight containers nested with each other, and the volume of the inner airtight container is 1 / 2 of the volume of the outer airtight container. one twenty-seventh;

[0027] Among them, the filling material A is an aqueous solution of ammonia and ethanol and air, the content of ammonia is 80.9%, and the content of ethanol is 17.5%. When filling at -40 ° C, the aqueous solution of ammonia and ethanol needs to fill 5% of the volume of the inner airtight container. %, the air pressure is one atmosphere; the filling material B is 1% ethanol solution of phenolphthalein and air, filled at -40°C, the volume of the ethanol solution of phenolphthalein is 10% of the volume of the outer airtight container, and the air pressure is one atmosphere .

[0028] This embodiment can indicate that the temperature of the object t...

Embodiment 2

[0031] In the one-time over-temperature detection method provided in this embodiment, filling material A and filling material B are respectively put into inner and outer airtight containers nested with each other, and the volume of the inner airtight container is 1 / 2 of the volume of the outer airtight container. one twenty-seventh;

[0032] Wherein, filler A is the aqueous solution of ammonia and ethanol and air, and the content of ammonia is 27.4%, and the content of ethanol is 48.3%, fills at -40 ℃, and the aqueous solution of ammonia and ethanol needs to fill the inner layer airtight container volume 5 %, the air pressure is one atmosphere; the filling material B is 1% ethanol solution of phenolphthalein and air, filled at -40°C, the volume of the ethanol solution of phenolphthalein is 10% of the volume of the outer airtight container, and the air pressure is one atmosphere .

[0033] This embodiment can indicate that the temperature of the object to be tested, which shou...

Embodiment 3

[0036] In the one-time over-temperature detection method provided in this embodiment, filling material A and filling material B are respectively put into inner and outer airtight containers nested with each other, and the volume of the inner airtight container is 1 / 2 of the volume of the outer airtight container. a quarter;

[0037] Wherein, filler A is water and air, fills at 0 ℃, and water needs to fill 5% of the volume of inner layer airtight container, and air pressure is 1.9 atmospheric pressure; Filler B is anhydrous copper sulfate powder and air, in When filling at 0°C, the anhydrous copper sulfate is 0.2 g, and the air pressure is one atmosphere.

[0038] This embodiment can indicate that the temperature of the object under test, which should always be between 0°C and 20°C, was once higher than 25°C.

[0039] The working principle of this embodiment is that the air pressure in the inner airtight container with higher air pressure increases faster than the outer airtig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com