Flow rate detection method for low-energy-consumption ultrasonic flow rate meter and system

A flow detection and ultrasonic technology, applied in the field of ultrasonic flowmeter design, can solve the problems of continuous vibration of the transducer, large system energy loss, inconvenient use, etc., and achieve the effects of reducing energy loss, improving measurement accuracy and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

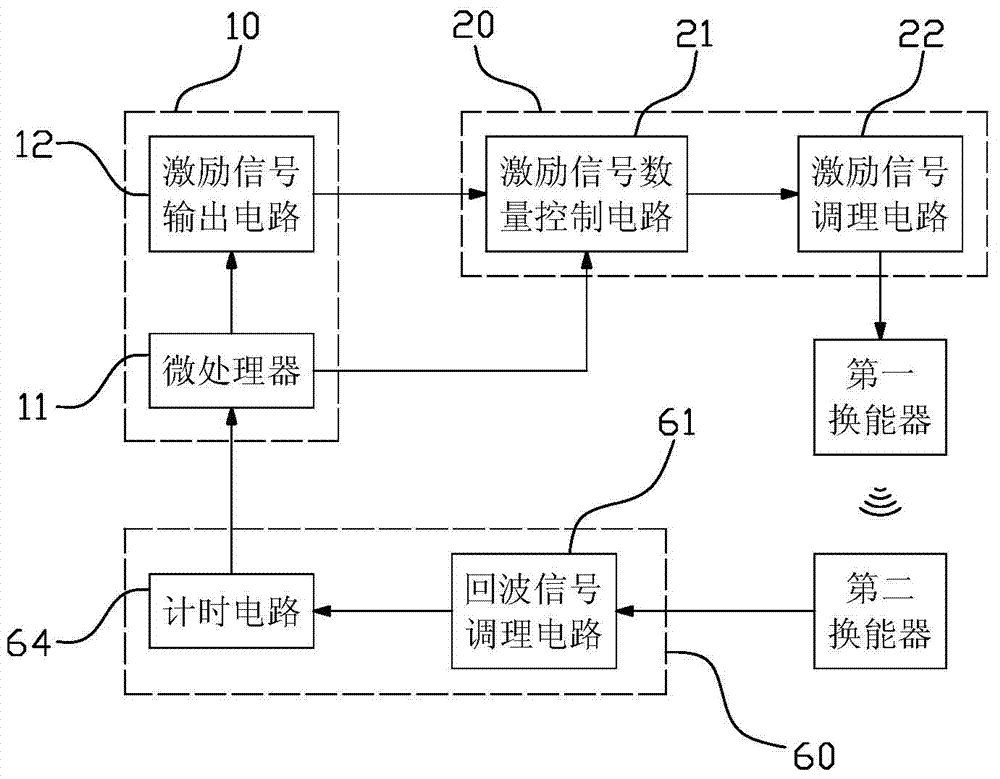

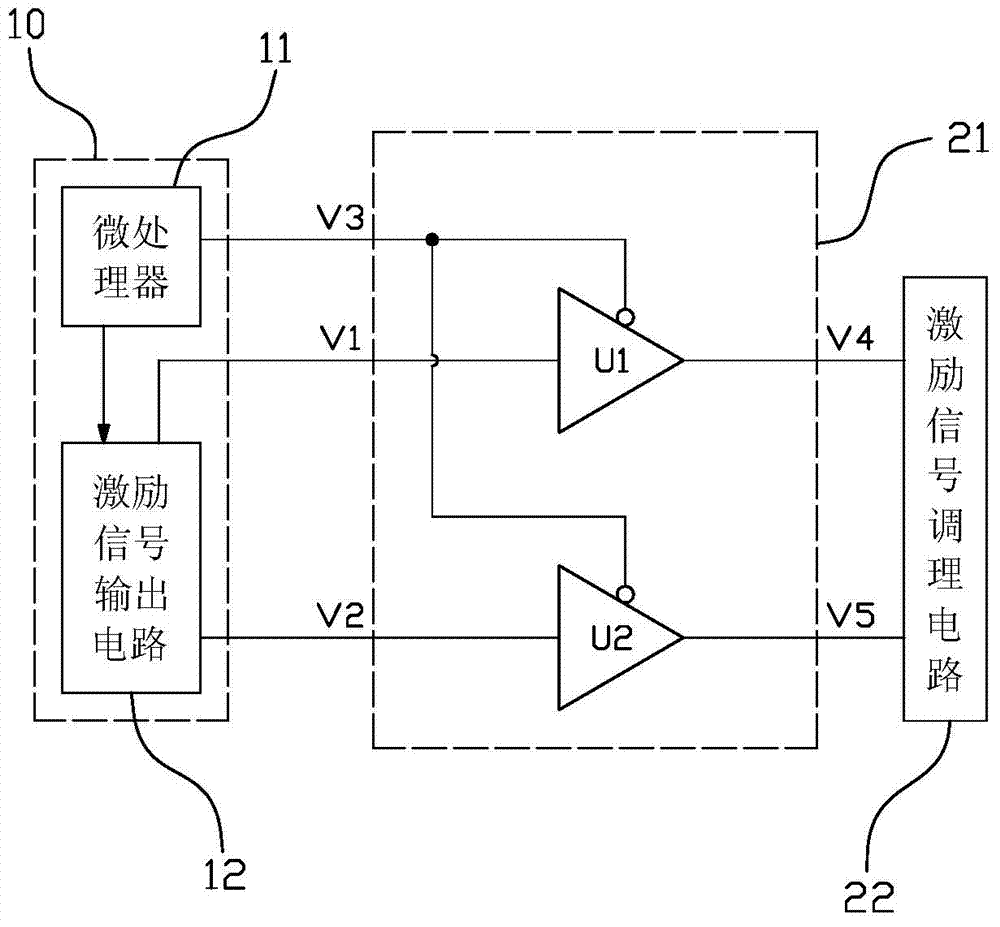

[0016] Combine below Figure 1 to Figure 6 , The present invention is described in further detail.

[0017] Refer to figure 2 , A flow detection method for a low-energy ultrasonic flow meter, including the following steps: (A) the main control module 10 generates a continuous excitation signal with a period of T and outputs it to the excitation signal quantity control circuit 21; (B) excitation signal The quantity control circuit 21 processes the excitation signal of the continuous period into the excitation signal of the specified number of cycles, and the specified period is greater than or equal to 6; (C) the first transducer emits ultrasonic waves after receiving the excitation signal of the specified number of cycles Signal; (D) the second transducer outputs the echo signal to the timing circuit 64 in the echo signal processing module 60 for timing after receiving the ultrasonic wave; (E) the timing circuit 64 outputs the result to the main control module 10, the main contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com