Portable straightness detection device

A detection device and flatness technology, applied in measuring devices, optical devices, instruments, etc., can solve problems such as detecting wire flatness, and achieve the effects of convenient operation, accurate precision, and improved work efficiency and economic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

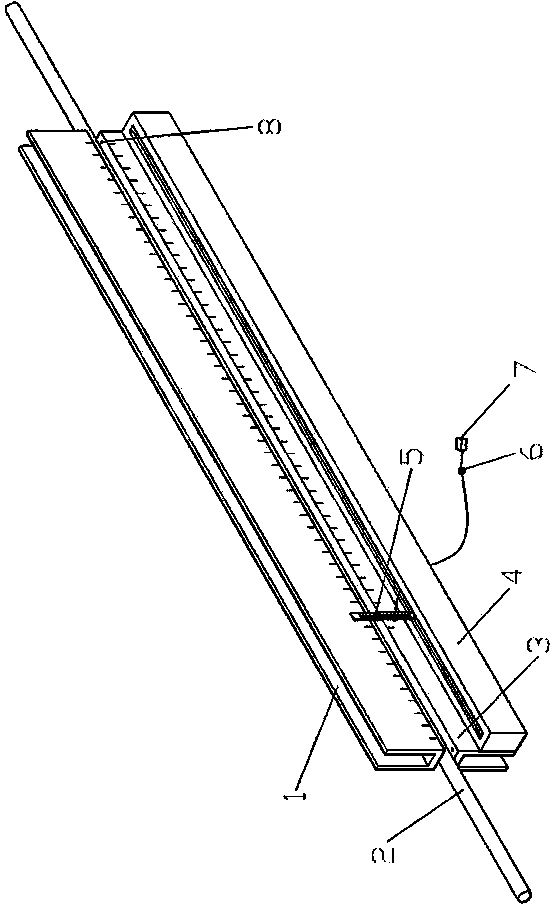

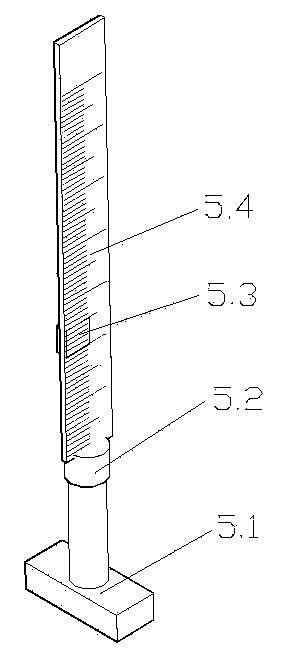

[0024] see Figure 1~Figure 3 , a portable flatness detection device of the present invention, which includes an upper dovetail 1 and a lower dovetail 3, the upper dovetail 1 and the lower dovetail 3 are arranged in parallel with their backs, and the wire 2 to be detected is fixed between the upper dovetail 1 and the lower dovetail 3 Between, one side of the lower dovetail 3 is provided with a chute guide rail 4, the chute guide rail 4 is provided with a measuring feeler gauge 5, the measuring feeler gauge 5 includes a base 5.1 and a feeler gauge 5.4, and the bottom of the feeler gauge 5.4 A connecting nut 5.2 is provided, a laser scanner 5.3 is arranged on the feeler gauge 5.4, the fixed base 5.1 is arranged in the chute of the chute guide rail 4, and an encoder 6 and a computing machine are arranged outside the chute guide rail 4 The processor 7, the laser scanner 5.3 is connected with the encoder 6, the encoder 6 is connected with the calculation processor 7, and the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com