Construction Technology of Reverse Method for Hoisting High-altitude Multi-storey Suspended Steel Structure

A construction technology and steel structure technology, applied in building construction, construction, construction materials processing and other directions, can solve the problems of large footprint of scaffolding, low construction efficiency, etc., to achieve safe and reliable construction, reduce costs and energy, save money The effect of the work surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

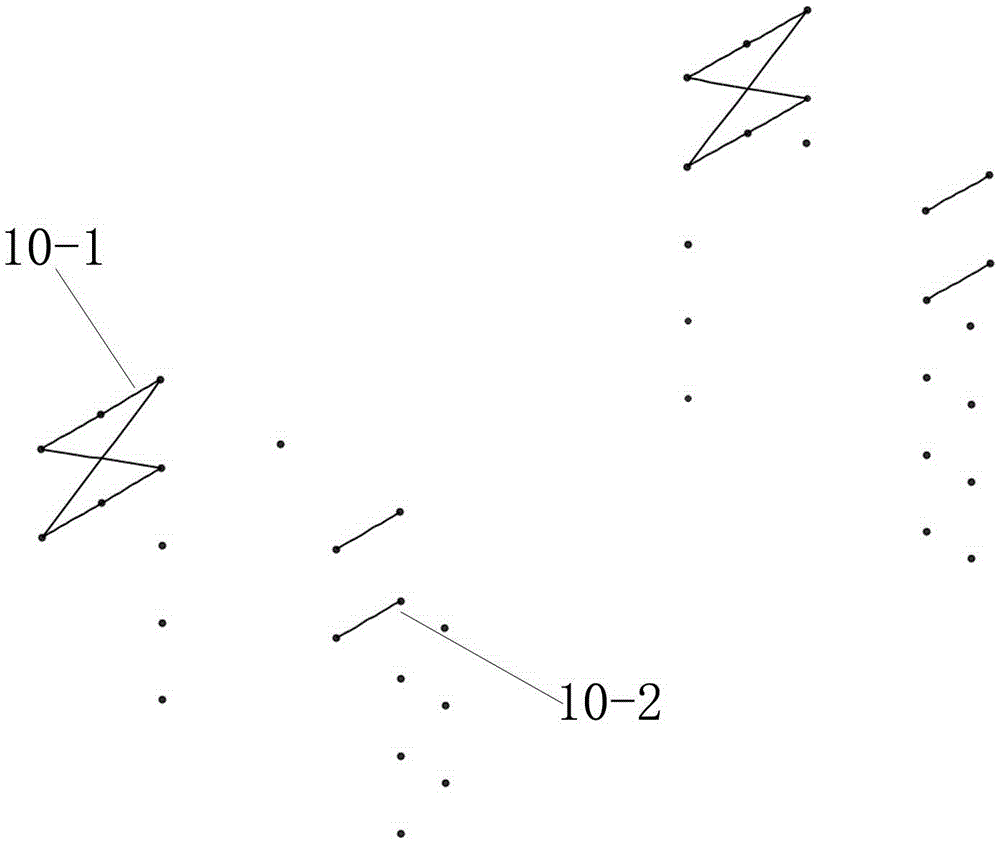

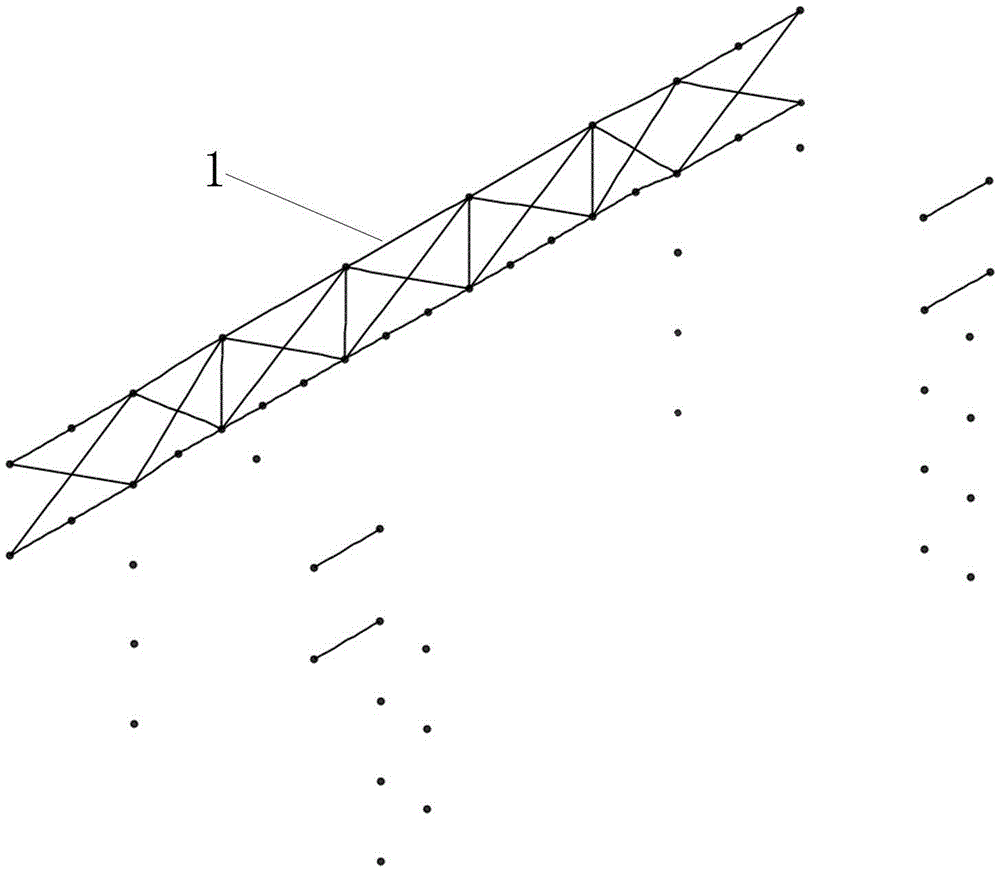

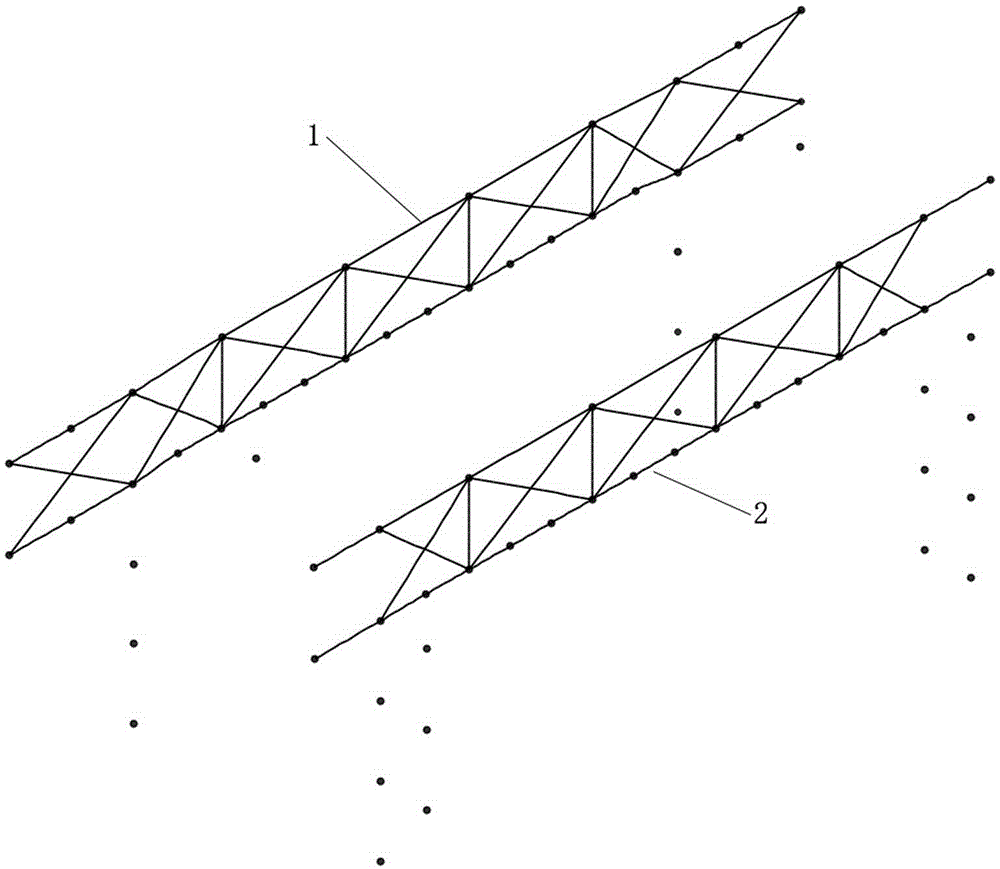

[0041] For a corridor installation project, the corridor has three floors, corresponding to the 10th, 9th, and 8th floors of the concrete building; the steel structure of the project is a suspended steel structure, and the corridor structure with functional functions from the 8th to the 10th floor passes through the 11th floor A system of steel trusses is suspended above the reinforced concrete structure. Therefore, the structure is dominated by 2 steel trusses, supplemented by 8-10 storey steel beams. Such stress characteristics require that the steel corridor should adopt a top-down construction sequence, that is, a "reverse construction method" construction sequence that is different from the conventional straight method.

[0042] The installation sequence is subdivided into 18 steps, which are:

[0043] Step 1: Installation of the first truss 1 (suspension) on the left side of the 11th floor ( figure 2 );

[0044] Step 2: Installation of the second truss 2 (suspension)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com