Construction method for thin wall housing body mould shell cast-in-place concrete building roof

A technology of thin-walled boxes and construction methods, which is applied to floors, building components, buildings, etc., and can solve problems such as side shifting, affecting construction quality, and grout leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

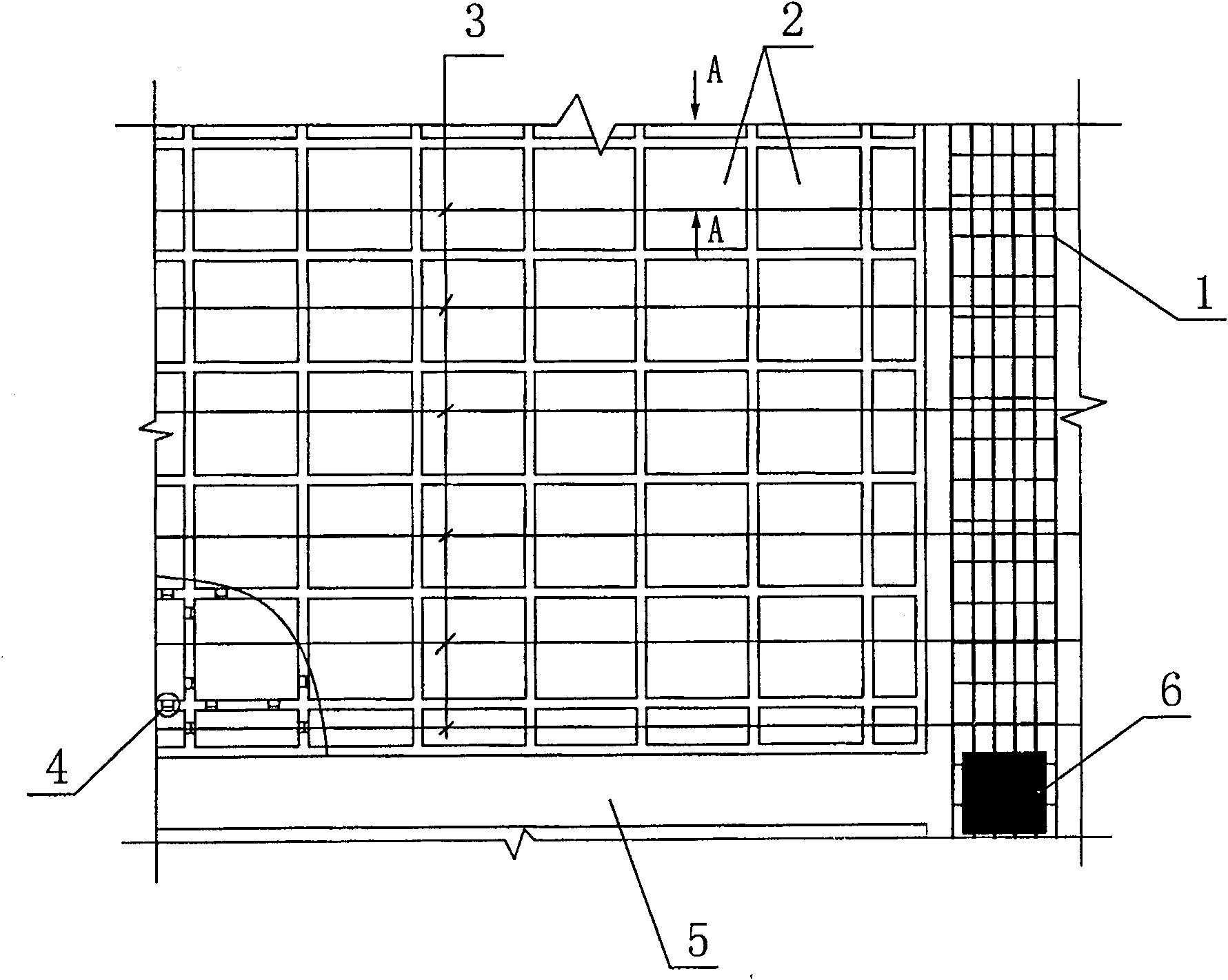

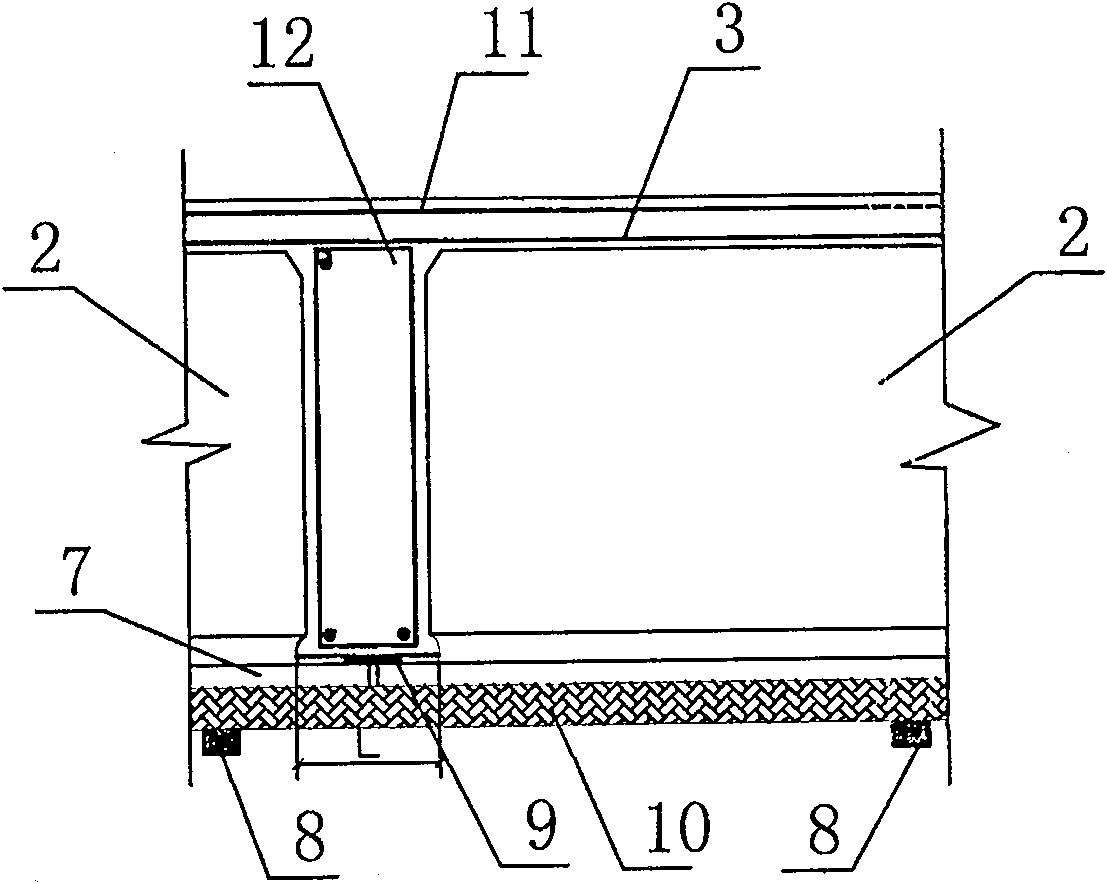

[0033] see Figures 1 to 3 , the construction method of the cast-in-place concrete floor of the thin-walled box formwork may include:

[0034] 1. Protection of finished products of thin-walled box formwork

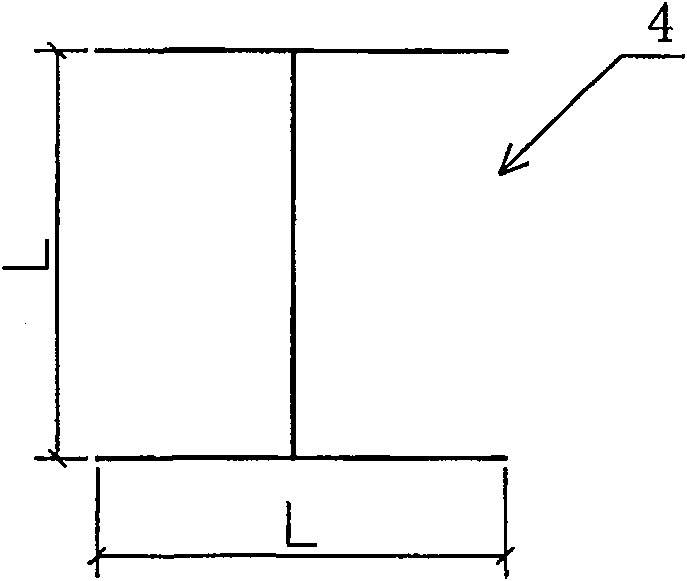

[0035] 1) A kind of thin-wall box formwork that is widely used at present is an integral hollow component made of ultra-high-strength inorganic cementitious material as the main raw material, attached with fiber reinforcement, and processed by professional manufacturers. The appearance of the thin-walled box formwork is as follows:

[0036] The length and width specifications of the main models of thin-walled box formwork are 900mm×900mm, 600mm×900mm, 300mm×900mm and 600mm×600mm, 300mm×600mm, 300mm×500mm.

[0037] 2) According to the requirements of the construction drawing and through calculation, draw the layout plan of the thin-walled box formwork on the floor, and then order the thin-walled box formwork according to the specifications and quantities in the layout.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com