Online thermal treatment, acid pickling and phosphating process of medium and high-carbon superfine steel wire for rope making

A pickling phosphating, medium-high carbon technology, applied in the field of metallurgy, can solve problems such as limited equipment capacity, achieve the effects of reducing the consumption of phosphating solution, reducing costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with specific examples.

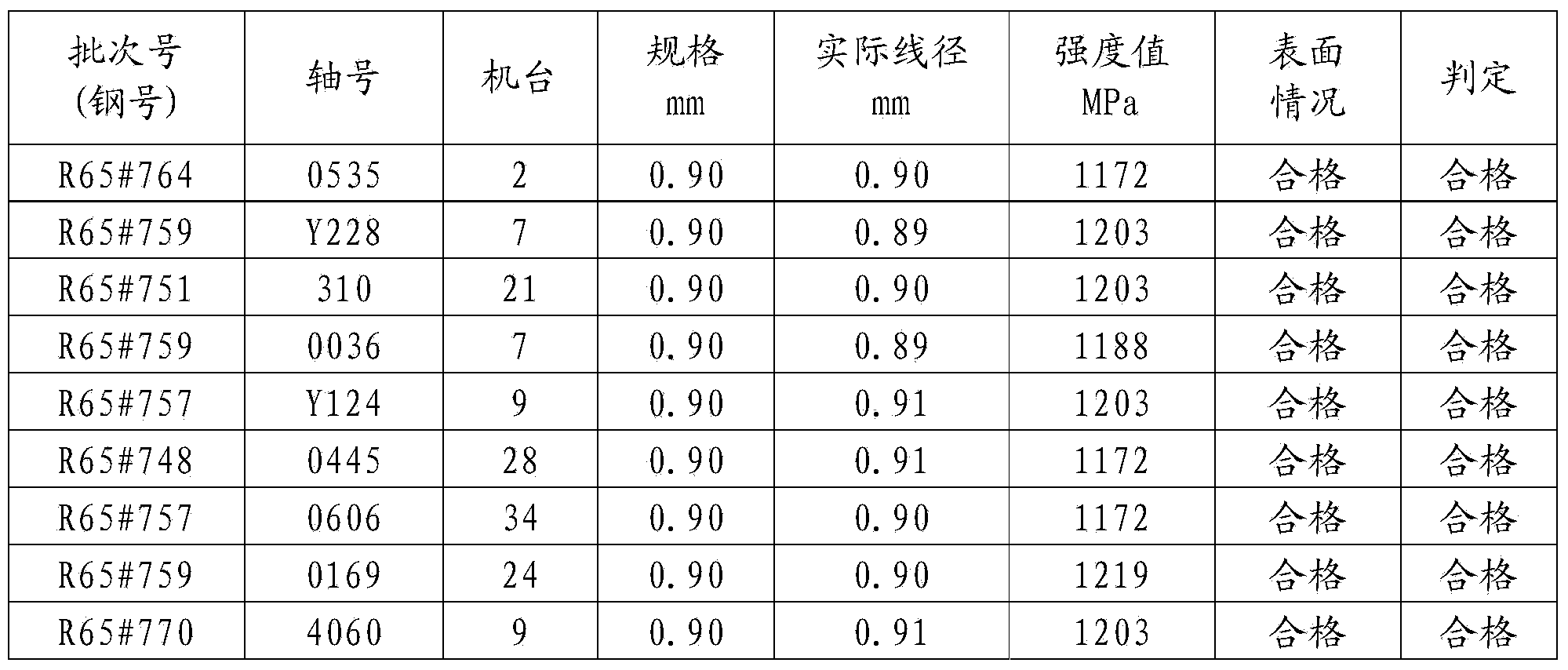

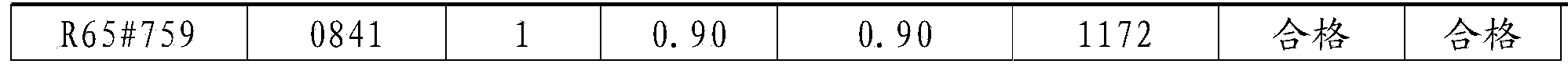

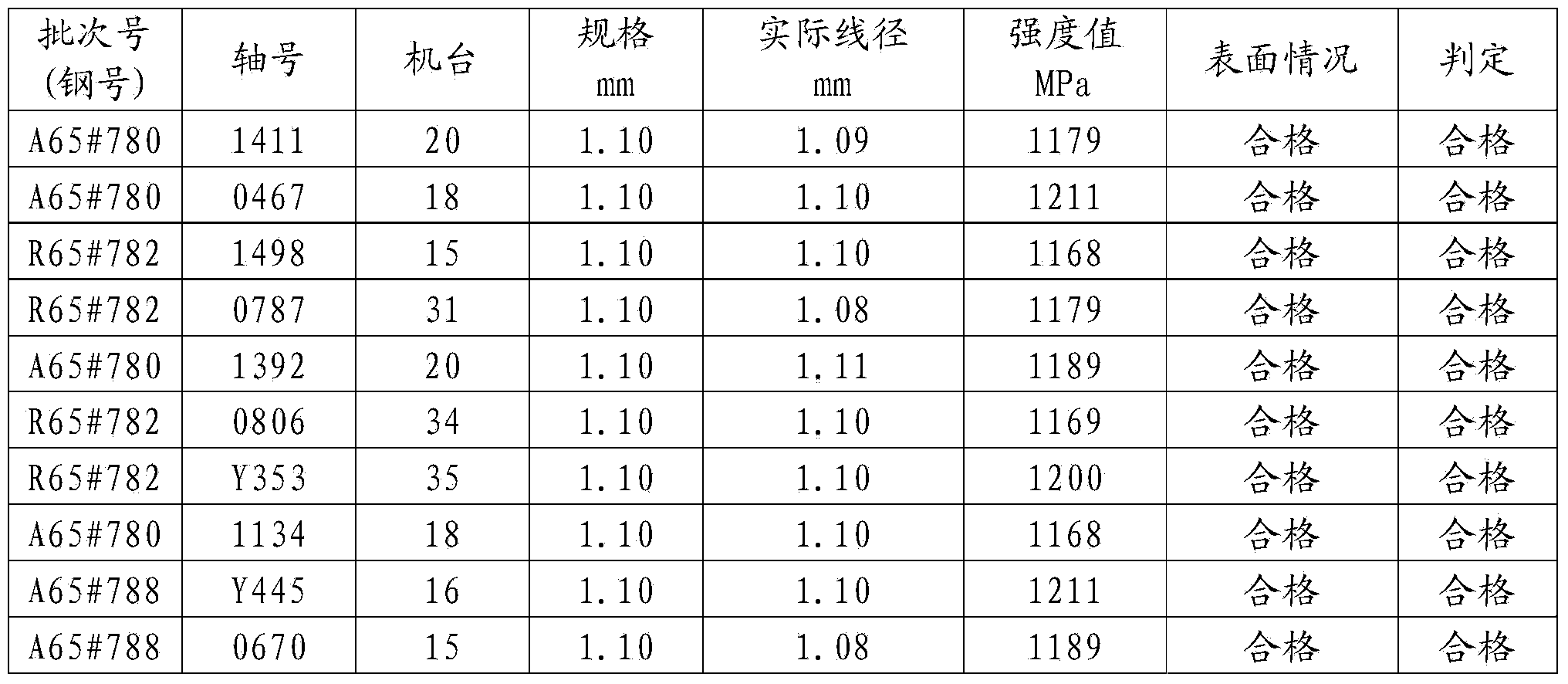

[0015] The on-line heat treatment pickling and phosphating process of medium and high carbon ultra-fine specification steel wire used for rope making in the present invention is suitable for the specification of φ0.8-1.3mm, and the steel type is high-quality carbon structural steel 45# steel, SWRH47A, SWRH62A, high-quality carbon structure For steel 65# steel and SWRH 72A products, the mass fraction of carbon content of each steel type is shown in Table 1.

[0016] Carbon content% (mass fraction) of each steel type Table 1

[0017] 45#

47A

62A

65#

72A

0.455~0.487

0.470~0.499

0.619~0.659

0.635~0.697

0.731~0.752

[0018] The on-line heat treatment pickling and phosphating process of medium and high carbon superfine steel wire for rope making includes the following steps: wire setting → steel wire heating + lead po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com