Soap stirring device

A stirring device and soap technology, which is applied in the field of machinery, can solve problems such as uneven dispersion, insufficient mixing of soap reaction liquid or soap reaction liquid, and low decontamination ability of soap or soap, so as to reduce production time and improve production Efficiency, the effect of increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

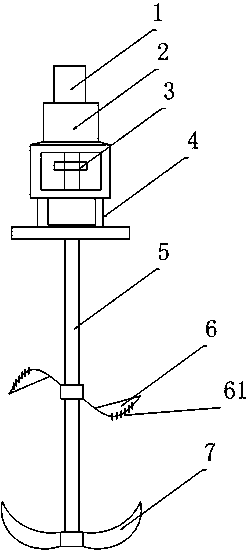

[0022] like figure 1 Shown, a kind of toilet soap mixing device comprises the motor 1 that is arranged on the top, the speed reducer 2 that is arranged on the bottom of motor 1, the frame that is arranged on the bottom of speed reducer 2, the shaft coupling 31 that is arranged on the inside of the frame, set The sealing element 4 at the lower part of the frame, the stirring shaft 5 is arranged under the sealing element 4, the stirring shaft 5 is connected with the coupling 31, the coupling 31 is connected with the motor 1, and the middle part of the stirring shaft 5 is provided with The upper stirring blade 6 and the lower stirring blade 7 are arranged on the lower part of the stirring shaft 5, and the upper stirring blade 6 and the lower stirring blade 7 are both sleeved on the stirring shaft 5, the upper stirring blade 6 is S-shaped, and the two ends of the S-shaped A willow-shaped sheet is provided, and the lower stirring blade 7 is crescent-shaped.

[0023] In the traditi...

Embodiment 2

[0025] Similar to Embodiment 1, the distinguishing feature is that the upper stirring blade 6 includes a left half leaf and a right half leaf, and the left half leaf and the right half leaf are both movably arranged on the stirring shaft 5 with the stirring shaft 5 as the center. Rotate up and down in the vertical plane. Being divided into two parts makes it easy to replace the upper stirring blade 6 and contributes to prolonging the service life of the entire stirring device.

[0026] A plurality of rings 61 are arranged on the edge of the sheet, and the intervals between the plurality of rings 61 are equal. The setting of the ring 61 can further stir the liquid level, so that the liquid is mixed more fully and the effect is more obvious.

[0027] The sizes of the multiple rings 61 are arranged from small to large from the stirring shaft 5 to the two ends of the upper stirring blade 6 . The larger rings 61 arranged at both ends of the upper stirring blade 6 can push a large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com