Ultra-high molecular weight anion biological polysaccharide grafted copolymer and preparation method thereof

A technology of ultra-high molecular weight graft copolymer, which is applied in the field of ultra-high molecular weight anionic biopolysaccharide graft copolymer and its preparation, can solve the problems that the molecular weight and structural properties are difficult to meet the actual needs, and the application is difficult to promote. Socioeconomic benefits, broad market prospects, and the effect of a wide range of pH values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

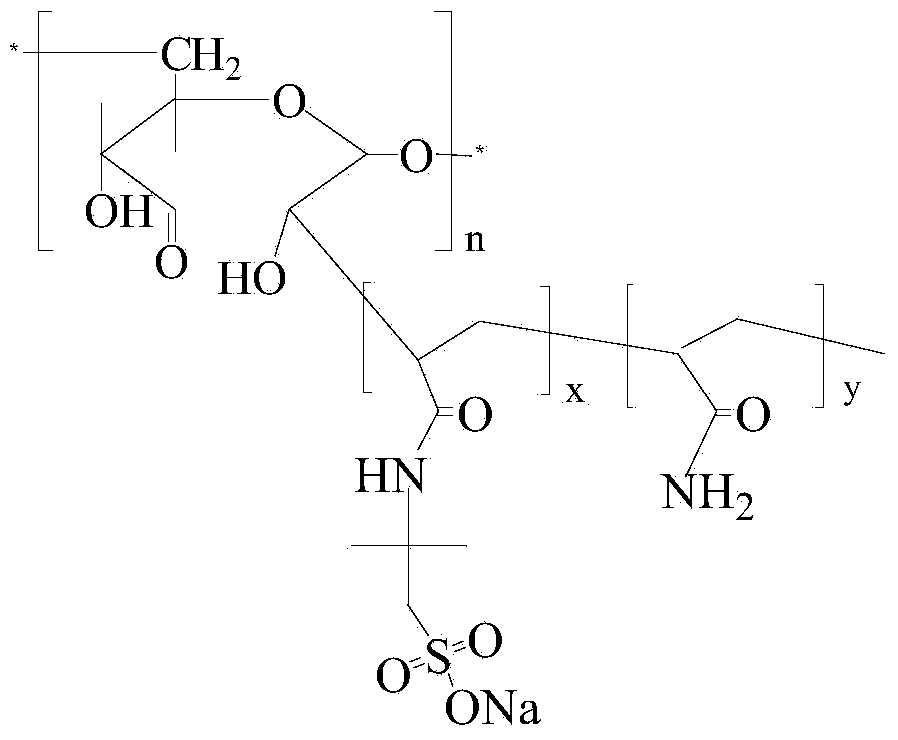

[0030] Preparation of graft copolymers of biological polysaccharides, acrylamide and sodium 2-acrylamido-2-methylpropanesulfonate

[0031] Preparation of 2-acrylamido-2-methylpropanesulfonic acid sodium aqueous solution: put the 2-acrylamido-2-methylpropanesulfonic acid aqueous solution with a mass fraction of 50% in an ice-water bath, and slowly add the concentration 30% sodium hydroxide aqueous solution, the pH of the final solution is 7-8.

[0032] In a 500ml three-neck flask, add 200g of a non-ionic biological polysaccharide solution with a mass concentration of 15%, start stirring, and then add 10g of acrylamide and a 42.3% mass concentration of 2-acrylamido-2-methylpropanesulfonate sodium solution 141.8g, after passing nitrogen to remove oxygen, heat up to 40°C, then add 1ml of 0.1mol / L cerium ammonium nitrate solution and 1.8g sodium sulfate, continue stirring for 20min, stop nitrogen flow, stop stirring, seal, keep warm for 3h, and finally Cool, take it out, add exces...

Embodiment 2

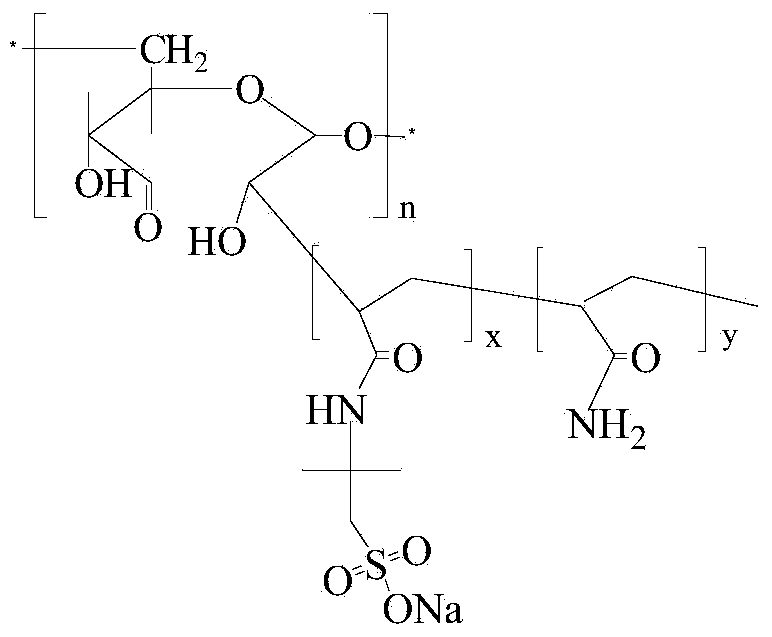

[0038] Preparation of graft copolymers of biopolysaccharides, acrylamide and acrylic acid

[0039] Prepare an acrylic acid monomer solution with a neutralization degree of 80%: Weigh 100g of acrylic acid and 44.4g of sodium hydroxide, place the acrylic acid in an ice-water bath, dissolve the sodium hydroxide in about 150ml of water, and slowly drop into In acrylic acid, a monomer solution with a neutralization degree of 80% and a monomer content of 34.2% can be obtained by stirring while dropping.

[0040]Add 100g of biological polysaccharide solution with a mass concentration of 15% into a 500ml three-neck flask, start stirring, add 15g of acrylamide and 131.58g of the above-mentioned acrylic acid solution in sequence, after purging nitrogen to remove oxygen, heat up to 30°C, and then add 0.1mol / L of 1ml of ammonium cerium nitrate solution and 2.8g of urea, continue to stir for 20min, stop nitrogen, stop stirring, seal, keep warm for 4h, finally cool, take out, add excess eth...

Embodiment 3

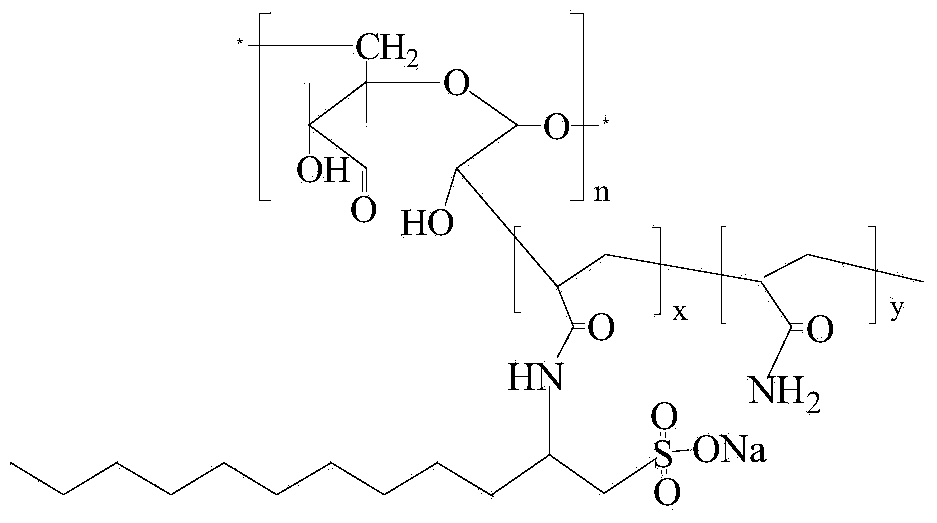

[0046] Preparation of graft copolymers of biological polysaccharides, acrylamide and 2-acrylamido-2-methylpropanesulfonic acid

[0047] Add 200g of biological polysaccharide solution with a mass concentration of 15% in a 500ml three-neck flask, start stirring, add 15g of acrylamide and 60g of 2-acrylamido-2-methylpropanesulfonic acid, and after purging nitrogen to remove oxygen, heat up to 40°C , and then add 2ml of 0.1mol / L cerium ammonium nitrate solution and 2g of sodium sulfate, continue to stir for 20min, stop nitrogen, stop stirring, seal, keep warm for 2h, finally cool, take out, add excess ethanol and stir, then suction filter, The filter residue was taken, washed three times with acetone, then dried in a vacuum oven to constant weight, and ground to obtain the final product.

[0048] The product can be used as paper-making auxiliary agent and water treatment agent in the range of sewage pH=2-12.

[0049] The structural formula of the product is:

[0050] Intrinsic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com