Novel punching rack supporting and jacking structure

A jacking and perforating technology, applied in the direction of lifting devices, can solve the problems of inconvenient construction, hidden dangers of construction safety, low efficiency, etc., and achieve the effects of easier operation, safe drilling and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

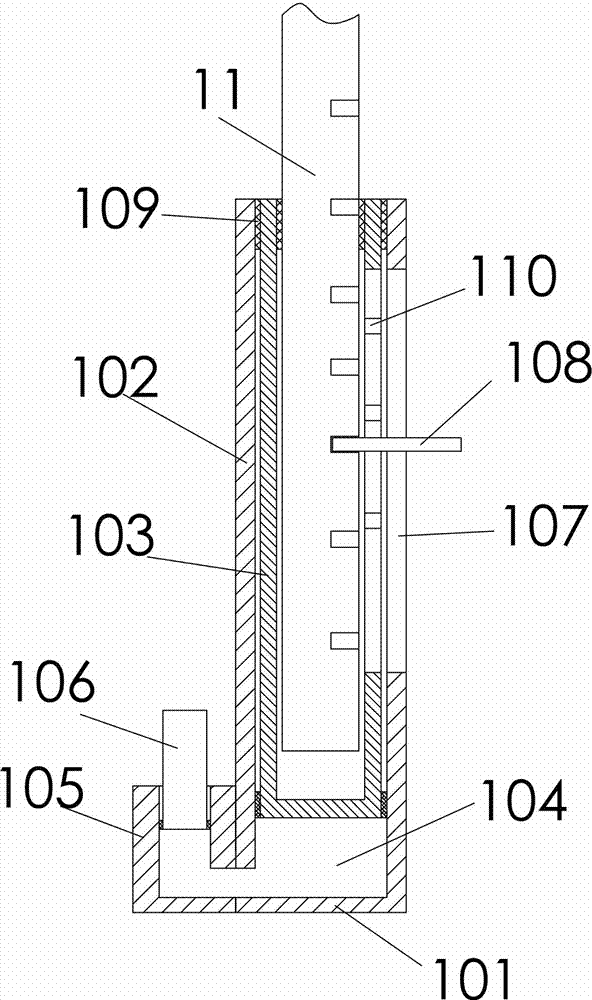

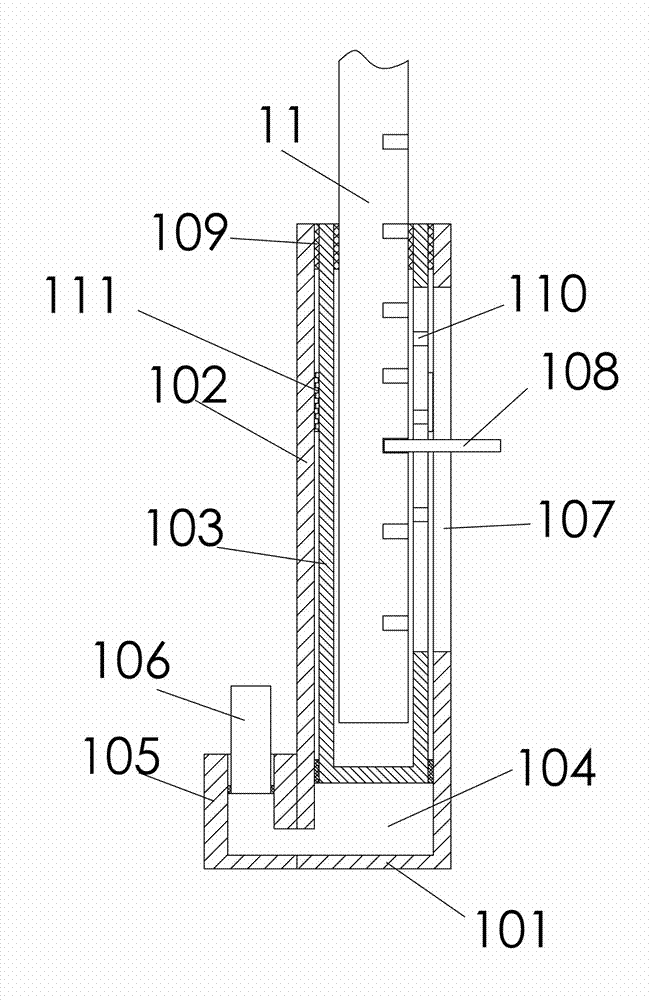

[0034] A novel perforated frame support jacking structure, comprising a support base and a support rod 11 inserted on the support base, the support base includes a base plate 101 and an outer casing 102 vertically arranged on the base plate; the support rod Inserted in the outer casing along the axial direction of the outer casing, the inner bottom of the outer casing is provided with a hydraulic oil chamber 104 for lifting the support rod, and the outer casing is also provided with a hydraulic cylinder 105 communicating with the hydraulic oil chamber. The cylinder is inserted with a piston rod 106 that can press the oil in the hydraulic cylinder into the hydraulic oil cavity for lifting the support rod. Linear bearings 109 are fixed at the upper ends of the lumens of the inner sleeve and the outer sleeve.

[0035] The support base also includes an inner sleeve 103 that is inserted in the outer sleeve along the axial direction of the outer sleeve and can slide up and down alon...

Embodiment 2

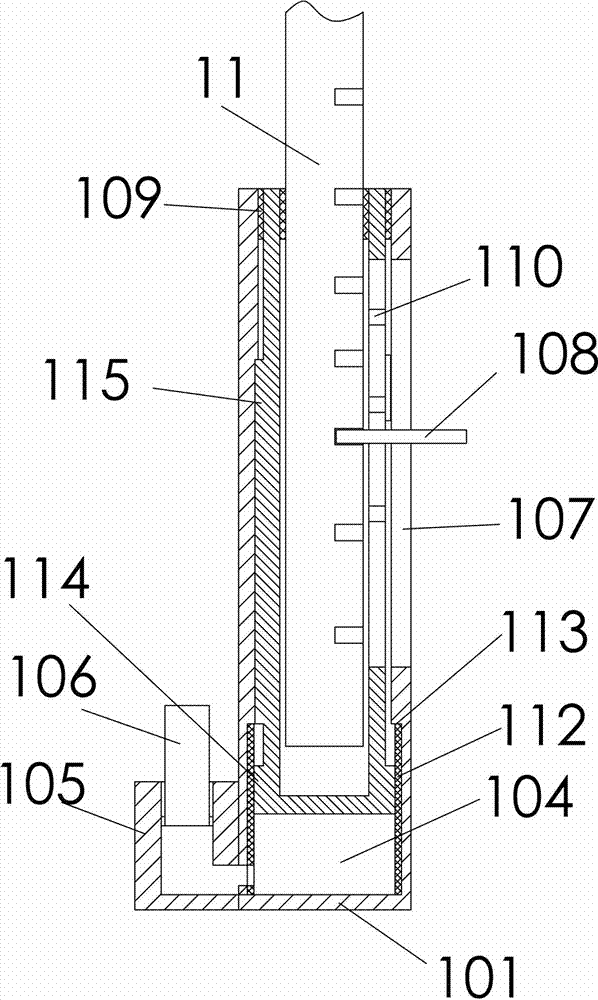

[0039] The difference from the above embodiments is that the base plate is provided with a stud tube 112 with external threads, and the inner wall of the lower end of the outer sleeve is provided with internal threads that are screwed and adapted to the stud tube, and the wall of the stud tube is A through hole for connecting the hydraulic oil chamber and the hydraulic cylinder is opened on the top.

Embodiment 3

[0041]The difference from the above-mentioned embodiment is that the lower part of the inner wall of the outer sleeve is recessed outward to form a limit step 113, and the outer wall of the inner sleeve is convexly formed below the limit step and is used to limit the inner sleeve up and down with the limit step. The stop step 114 of the sliding travel range. The inner wall of the outer casing and the outer wall of the inner casing are respectively provided with adapted guide ribs (115) and guide grooves along the axial direction of the outer casing. Therefore, it is used to prevent the inner sleeve from rotating circumferentially in the outer sleeve, and to ensure that the handle does not drive the inner sleeve when the support rod is rotated to prevent the positioning transverse groove from being covered by the outer sleeve. At the same time, it can also play a guiding role, making the entire structure Movement is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com