Hemispherical Pneumatic Grinding Wheel Electrostatic Sand Planting System with Wear Detection

A pneumatic grinding wheel, electrostatic sand planting technology, applied in grinding devices, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of inability to plant sand, inability to real-time online detection and feedback control, etc., to improve uniformity and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

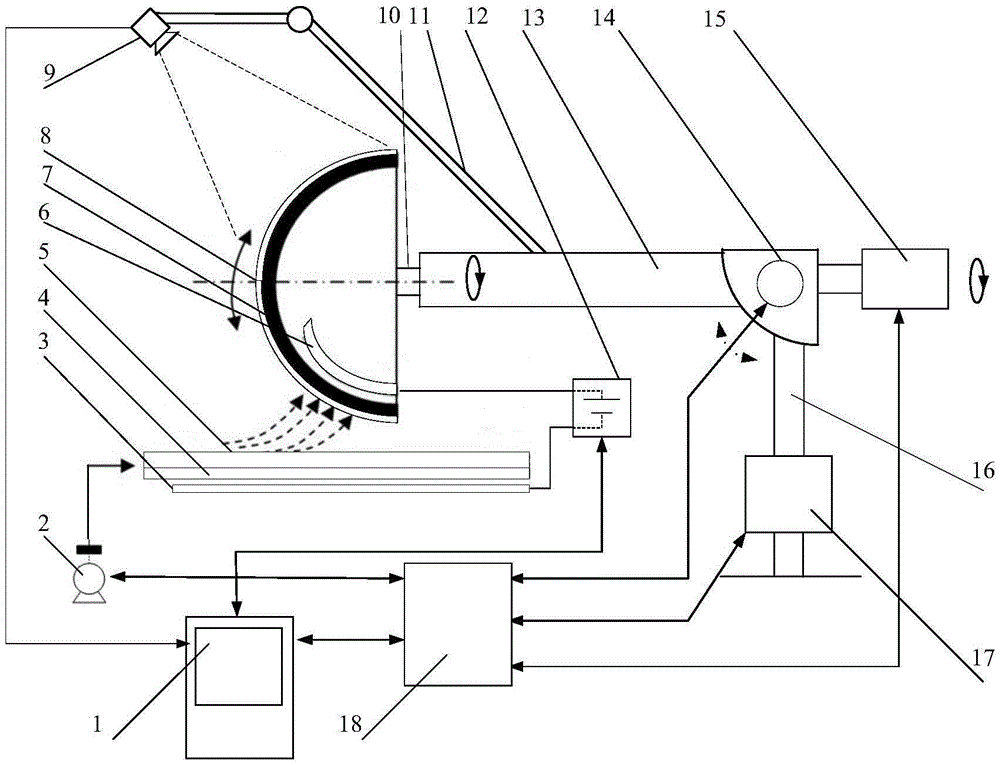

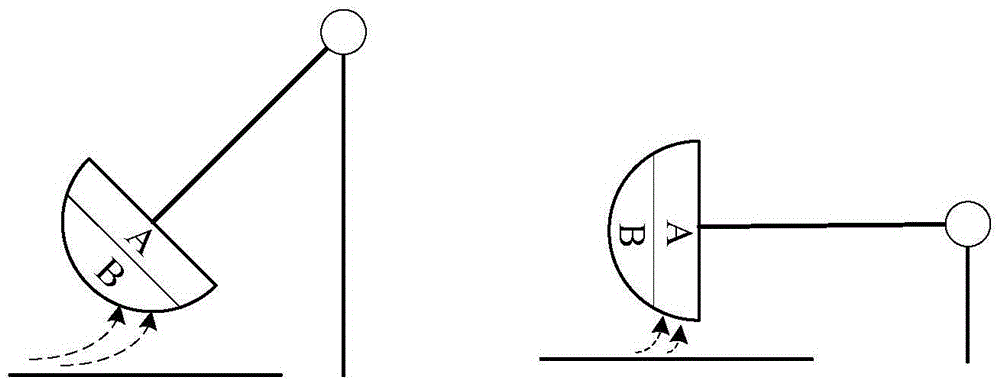

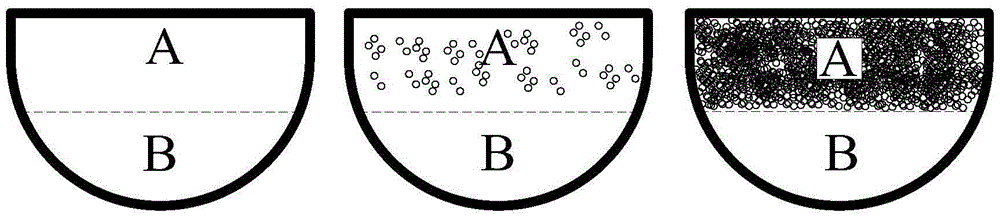

[0022] Embodiment 1 The hemispherical pneumatic grinding wheel electrostatic sand planting system with abrasive detection described in the present invention includes an electrostatic sand planting module for realizing the uniform consolidation of abrasive grains on the surface of the pneumatic grinding wheel through electrostatic means, and a device for controlling the movement state of the grinding wheel. A grinding wheel movement module, an image detection module for real-time online collection of images of abrasive grains on the surface of the pneumatic grinding wheel, and a main control system for realizing the electrostatic sand planting of the hemispherical pneumatic grinding wheel; the electrostatic sand planting module corresponds to the grinding wheel movement module The control motor is connected, the signal input end of the grinding wheel movement module is connected with the signal output end of the main control system, and the signal output end of the image detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com