Environment-friendly polyester net membrane culture medium packing

An environmentally friendly polyester and strain culture medium technology, which is applied in the field of polyester manufacturing, can solve the problems of inability to uniformly distribute strains, uneven distribution of microorganisms, shedding, etc., and achieve the effects of increasing air permeability and water permeability, saving labor, and easy decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementations provided according to the present invention will be described in detail below with reference to the drawings and embodiments.

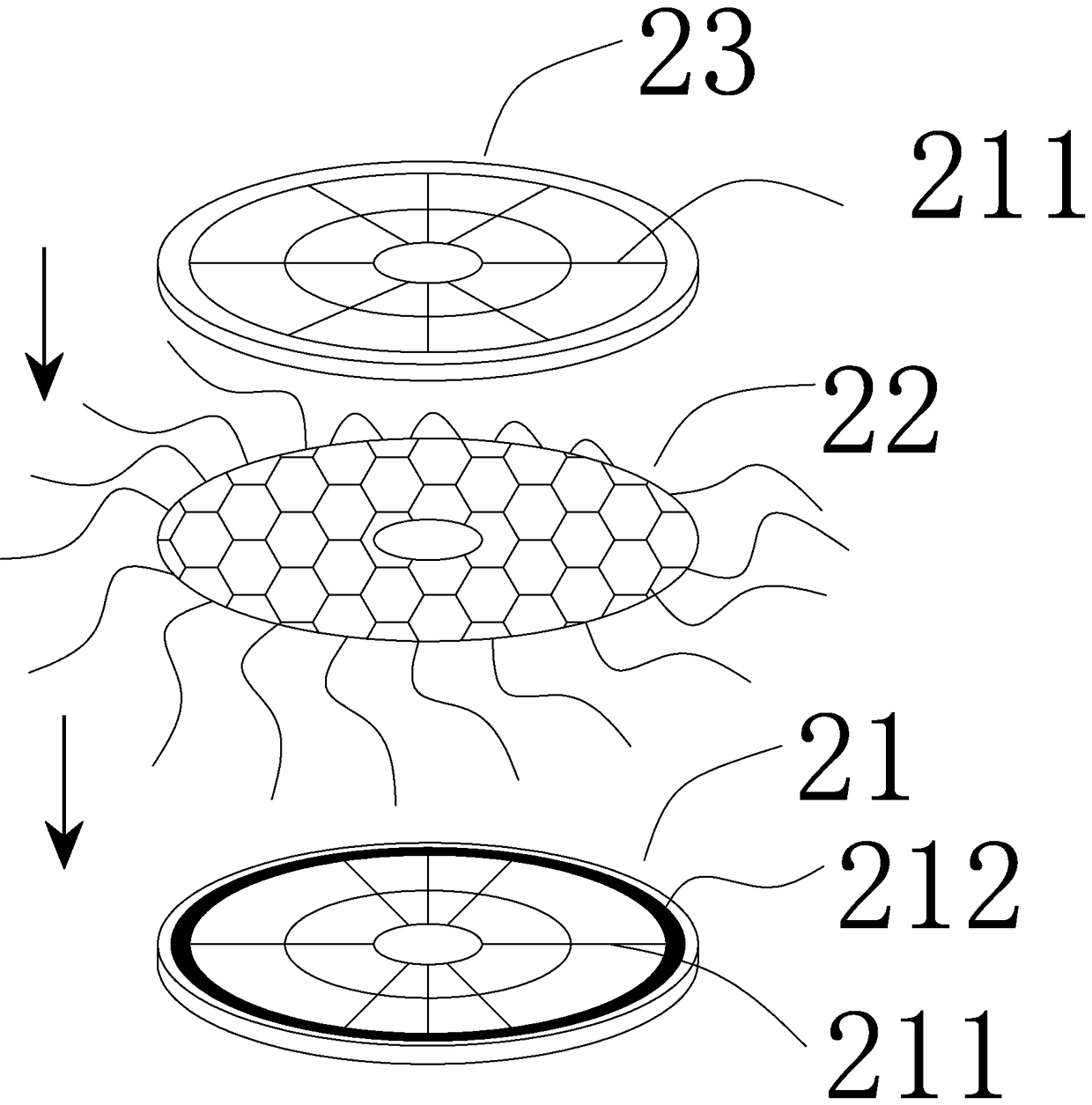

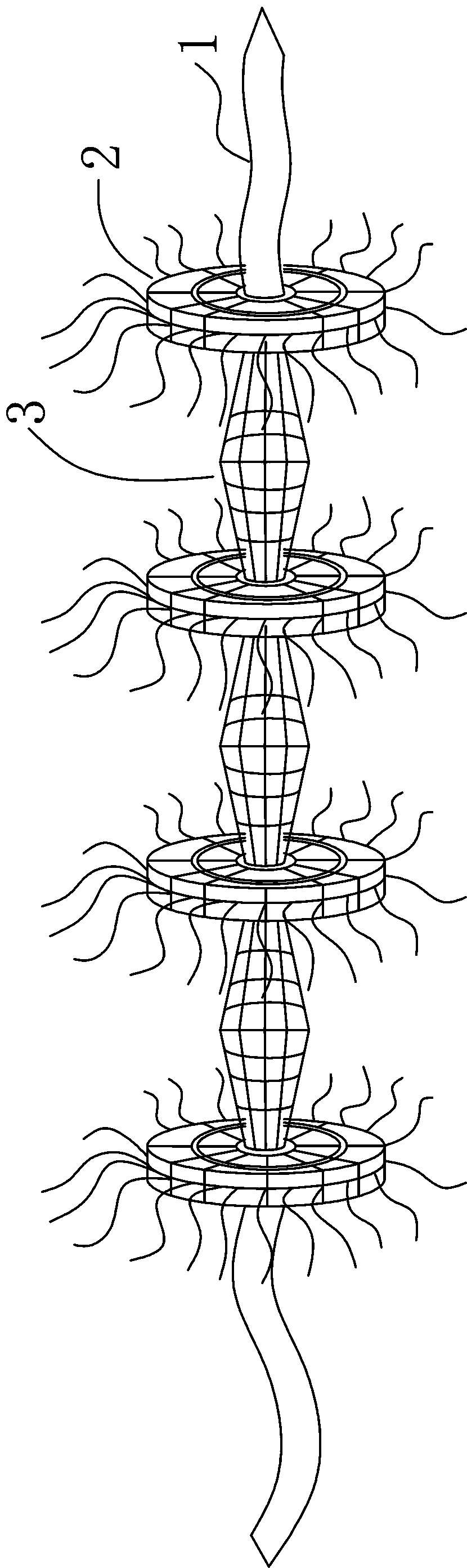

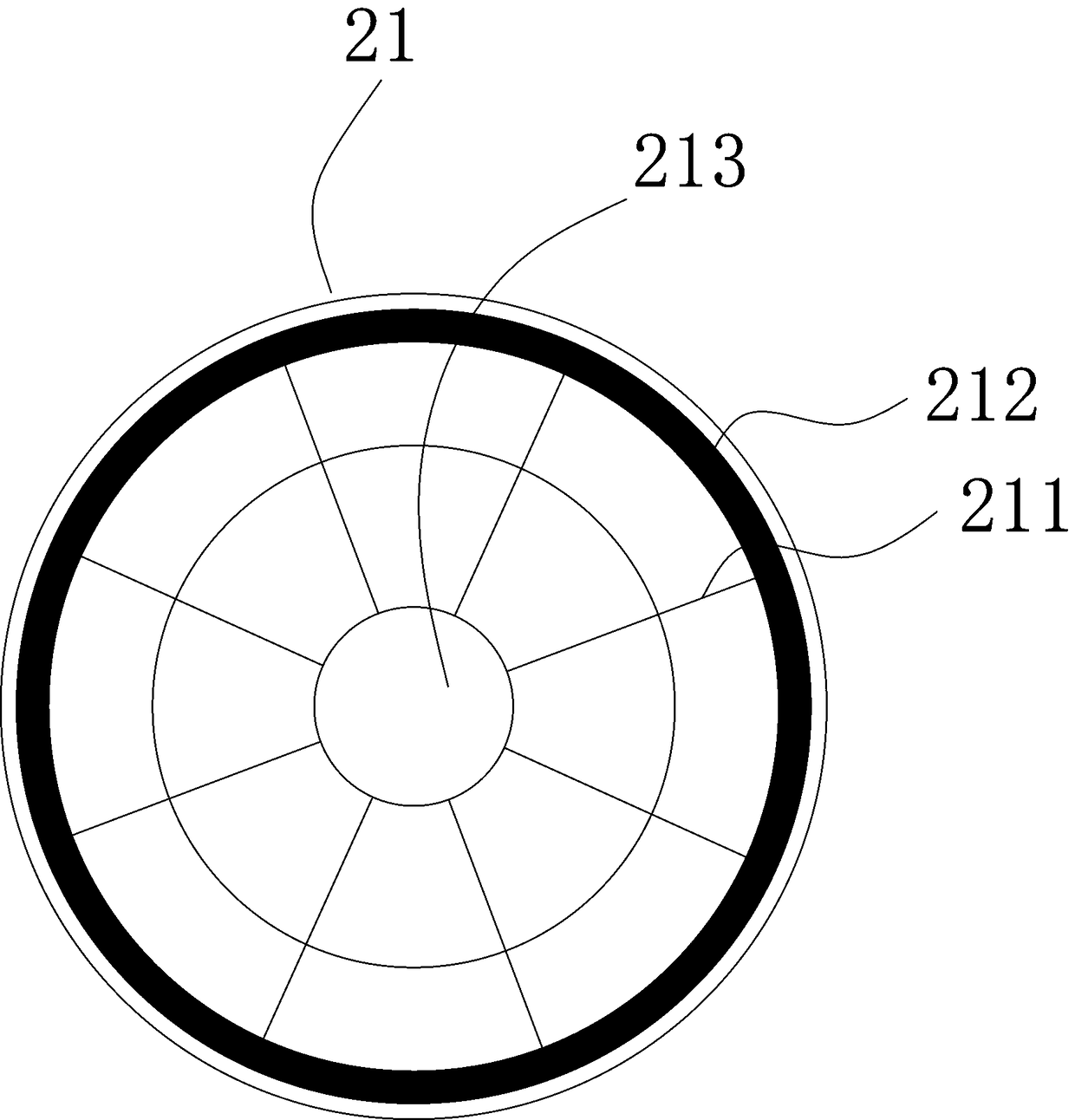

[0025] like Figure 1~5 As shown, a kind of environment-friendly polyester omentum medium filler comprises a nylon rope 1, and the nylon rope 1 is sequentially sleeved with a strain culture medium filler 2, a spacer ring 3 separating the strain culture medium filler 2, Sequentially cyclically socketed on the nylon rope 1 to form a group of environmentally friendly polyester omentum medium fillers; the strain culture medium sheet filler 2 passes through the first ring piece 21 and the second ring piece 23 to cover the omentum of the polyester omentum 22 221 is locked between the first ring piece 21 and the second ring piece 23, and through the clamping of the first ring piece 21 and the second ring piece 23, one end of the polyester wire 222 is locked twice to prevent the polyester wire 222 from gathering The ester ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com