A positioning device and positioning method for multi-face milling of casting molds

The technology of a positioning device and a fixing device is applied in the field of positioning devices for multi-face milling of casting molds, which can solve the problems of poor accuracy, scrapping, and difficult to control, and achieve the effects of fast positioning speed, accurate positioning and easy debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

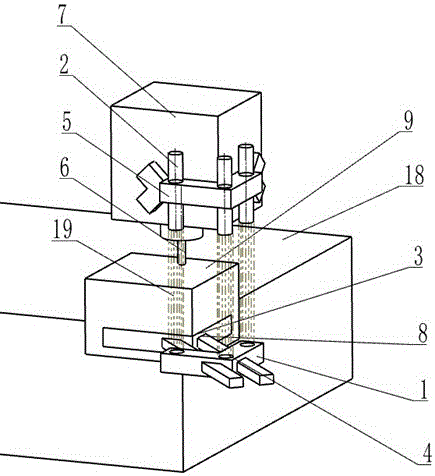

[0032] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not used to limit the present invention.

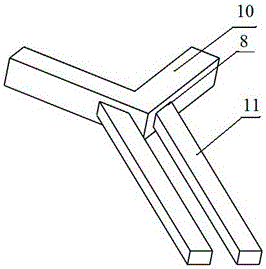

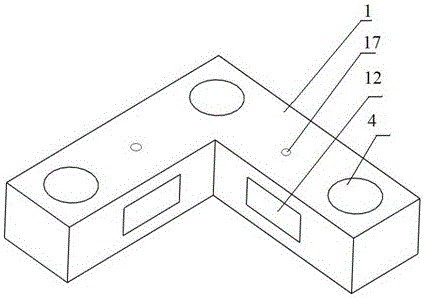

[0033] Combine Figure 1 to Figure 7 The positioning device for multi-face milling of casting molds includes an upper positioning device and a lower positioning device. The upper positioning device is fixedly connected to the mobile arm 7 and the mobile arm 7 is fixedly connected to the main transmission device 20 of the CNC milling machine of the machine tool. , The moving arm 7 can move in the horizontal and vertical directions, the lower positioning device is attached to a processing right angle of the blank 18 placed on the processing platform 21 of the machine tool, and the laser 2 provided on the upper positioning device emits The laser beam 19 corresponds to the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com