Three-directional follow-rest device

A technology of follower tool holder and fixed frame, which is applied in the field of follower tool holder, can solve the problems of screw rod length difference, deformation, etc., and achieve the effects of improving machining accuracy, solving insufficient positioning, and avoiding tool deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments. It will be apparent, however, to one skilled in the art that the described embodiments may be practiced without some or all of these specific details. In other instances, well known processing steps have not been described in detail.

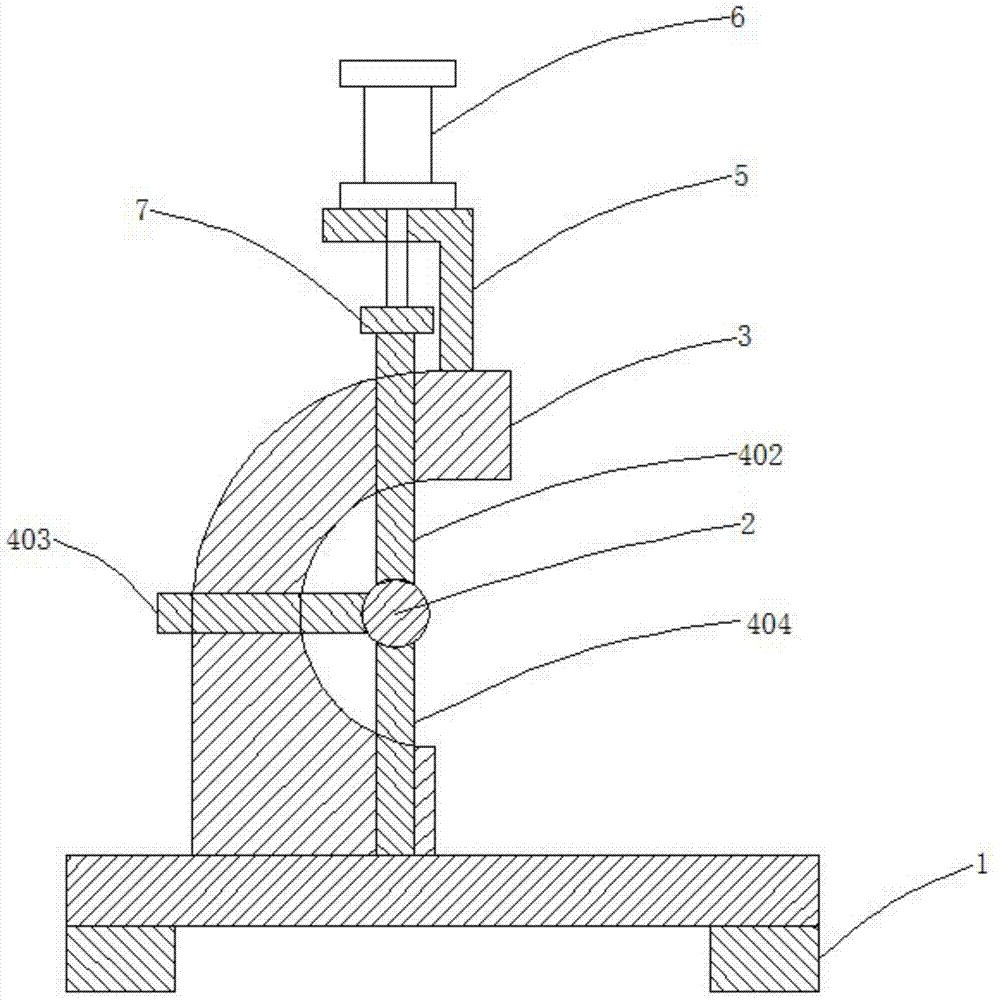

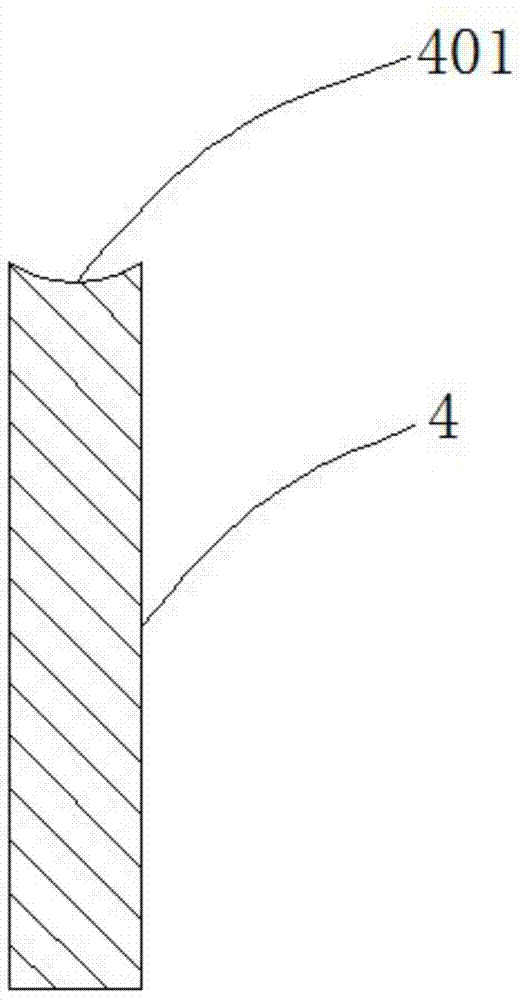

[0021] like figure 1 , figure 2 As shown, it includes a lathe 1, a lead screw 2, a bracket 3, a mandrel 4, a fixed frame 5, a cylinder 6, a telescopic plate 7, a support surface 401, a first mandrel 402, a second mandrel 403, and a third mandrel 404 , the bracket 3 is located on the top of the lathe 1, and the two are connected by threads, the ejector rod 4 is located on the inner wall of the bracket 3, and its shape is cylindrical, and the fixed frame 5 is located on the outer wall of the bracket 3, and its shape is rectangular. 5 at the center of the top, the two are connected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com