Build a photovoltaic power station with photovoltaic modules and composite buoyancy materials to make electrolyzed water on the lake

A technology of photovoltaic modules and buoyant materials, applied in photovoltaic power stations, photovoltaic power generation, photovoltaic module support structures, etc., can solve problems such as increased power consumption, difficulty in finding, and inability to drink normally, so as to achieve long service life and improve health. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

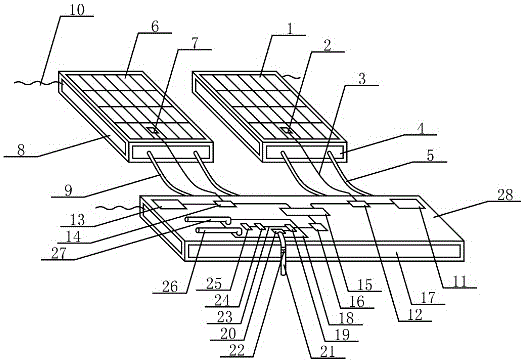

[0035] The current output from the monocrystalline silicon solar cell A installed on the top surface of the PIN structural foam composite sandwich buoyancy matrix material platform A is input to the controller A and the confluence installed on the PIN structural foam composite sandwich buoyancy matrix material platform C, The current output from the monocrystalline silicon solar cell B installed on the top surface of the PIN structural foam composite sandwich buoyancy matrix material platform B is input to the controller B and the confluence installed on the PIN structural foam composite sandwich buoyancy matrix material platform C, The current output from the confluence passes through the shunt in the electrolytic water machine to supply power to the electrolytic tank and the water suction pump respectively. The water sucked in by the water suction pump through the suction pipe enters the electrolytic water machine through the filter screen, and is electrolyzed in the electroly...

Embodiment 2

[0037] The current output from the polycrystalline silicon solar cell A installed on the top surface of the PIN structure foam composite sandwich buoyancy matrix material platform A is input to the controller A and the current collector installed on the PIN structure foam composite sandwich buoyancy matrix material platform C, from the installation The current output from the polycrystalline silicon solar cell B on the top surface of the PIN structure foam composite sandwich buoyancy matrix material platform B is input to the controller B and the confluence installed on the PIN structure foam composite sandwich buoyancy matrix material platform C, and output from the confluence The current passes through the shunt in the electrolyzed water machine to supply power to the electrolytic cell and the water suction pump respectively. The water sucked by the water suction pump through the suction pipe enters the electrolyzed water machine through the filter screen, and is electrolyzed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com