Convenient-to-manufacture electric connector component

A technology for electrical connectors and components, which is applied to the parts, connections, electrical components of connecting devices, etc., and can solve problems such as poor consistency of sockets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

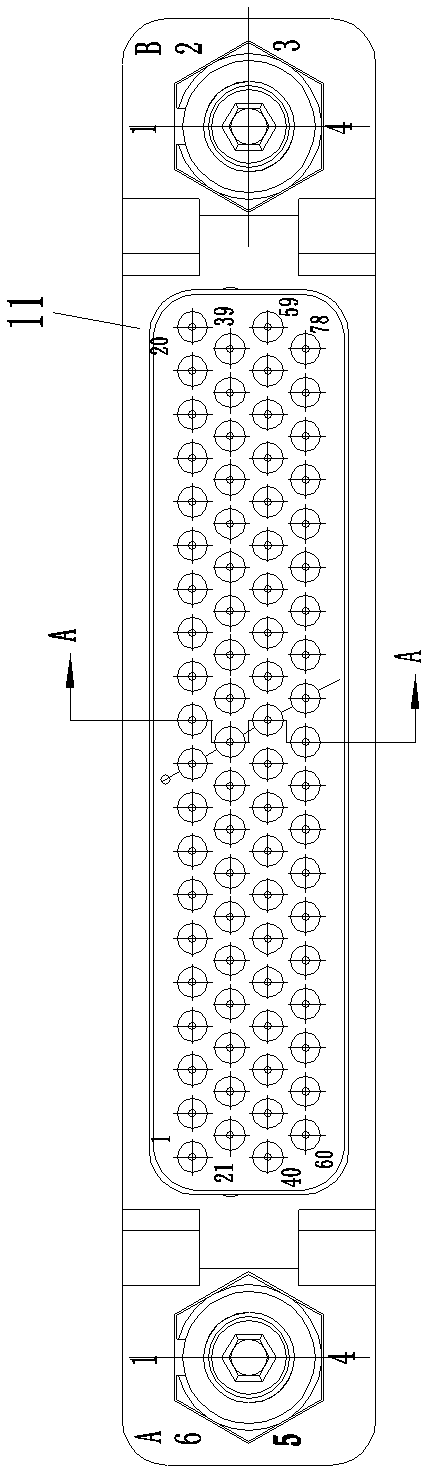

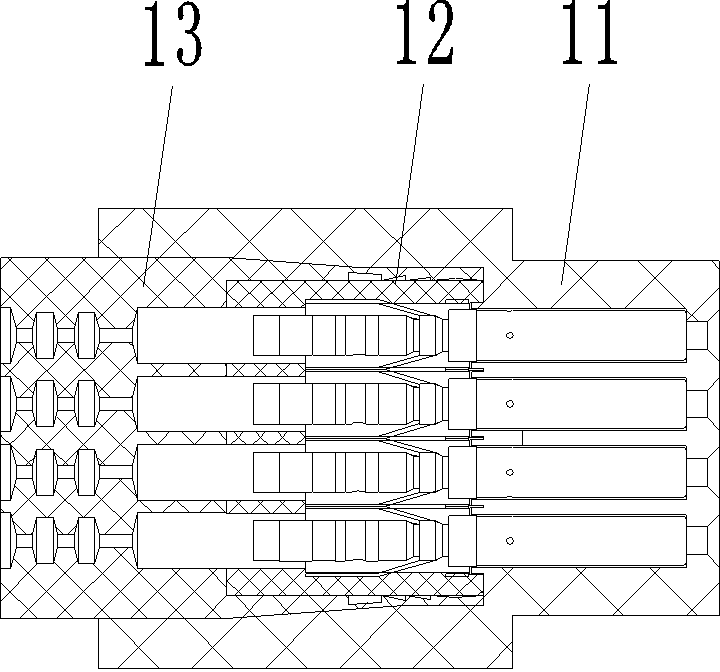

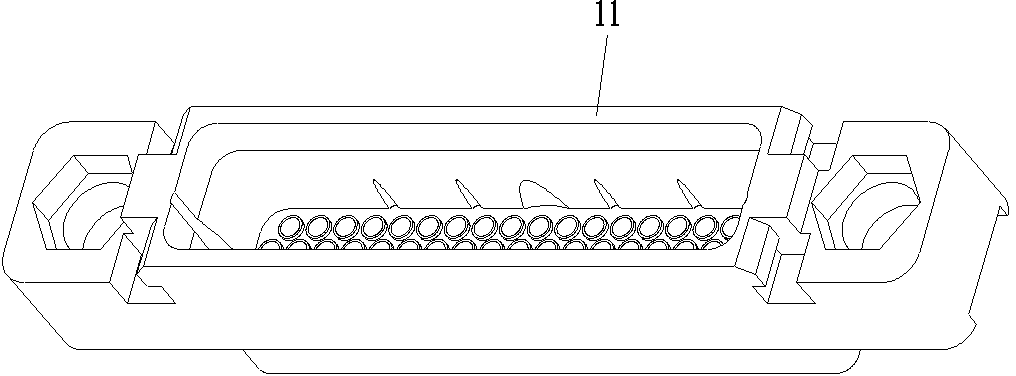

[0028] Embodiments of electrical connector assemblies that facilitate manufacture, such as Figure 1-9 As shown, the easy-to-manufacture electrical connector assembly includes a plug and a receptacle.

[0029] The plug includes a plug insulator 11, a plug insulating pressure plate 12 and a plug sealing body 13. The plug insulator 11 has an inner hole, the plug insulating pressing plate 12 is arranged in the inner hole of the plug insulator 11, and the plug sealing body 13 is directly injection molded on the plug insulator 11. in the inner hole.

[0030] Before the injection molding of the plug sealing body 13 , the plug insulator 11 and the plug insulating pressing plate 12 form an insert structure, and the insert structure ensures the reliability of the connection between the plug insulating body 11 and the plug insulating pressing plate 12 . In addition, grooves extending forward and backward are provided on the wall of the hole where the inner hole of the plug insulator 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com