Modeling method of asymmetric spur gear pair

A modeling method, asymmetric technology, applied to components with teeth, belts/chains/gears, portable lifting devices, etc., can solve the problem of easy loss of geometric information, cannot realize continuous dynamic simulation analysis of gears, and increase gear research and design and analysis workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Below in conjunction with accompanying drawing and specific embodiment, further elaborate the present invention, the modeling method of a kind of asymmetric cylindrical spur gear pair of this embodiment comprises the following several steps:

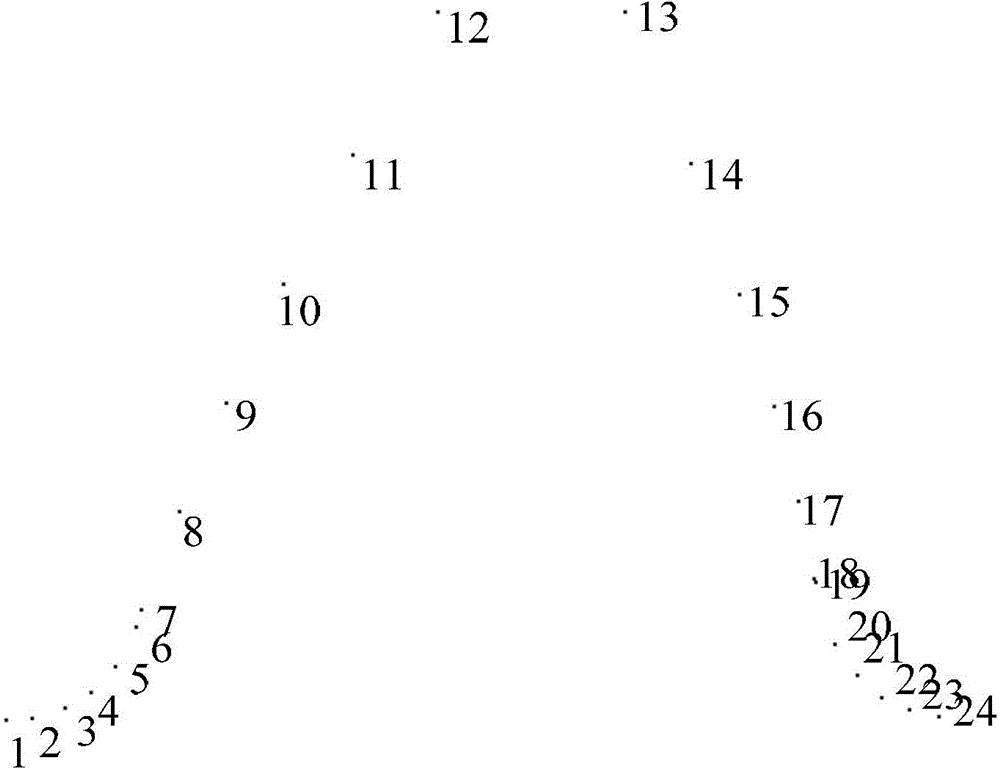

[0055] ① Parametric establishment of asymmetrical involute tooth profile curve:

[0056] Table 1: Modeling parameters of asymmetric spur gears

[0057] The number of teeth of the driving gear n1

45

Number of teeth of the driven gear n2

22

Modulus M

3mm

tooth width B

22mm

Pressure angle AD on the pressure side

28°

Non-pressure side pressure angle AC

20°

Addendum height factor HA

1

Head Clearance Coefficient CC

0.25

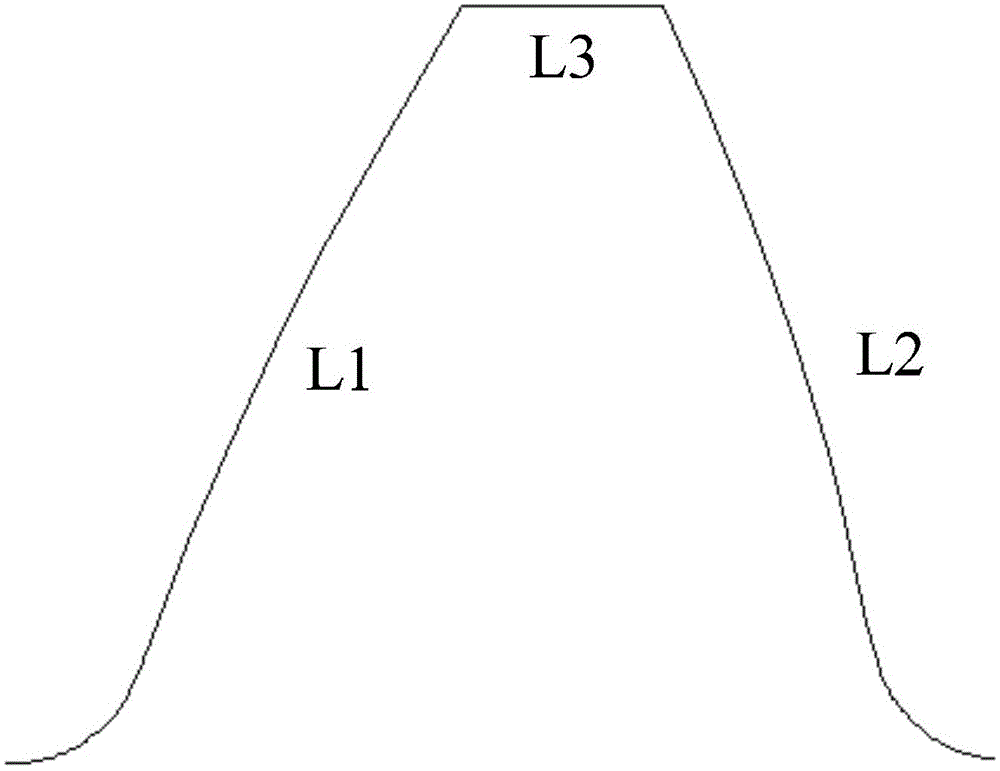

[0058] 1.1 The tooth profile curve of the asymmetric involute gear is divided into four parts: the pressure side tooth profile curve, the pressure side dedendum transition curve, the non-compression side tooth profile curve, and the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com