Fixation system capable of improving paper separation accuracy

An accuracy and paper-based technology, applied in the system field, can solve problems such as separation errors, paper jams, and easy displacement, and achieve the effect of ensuring integrity and improving the quality of fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

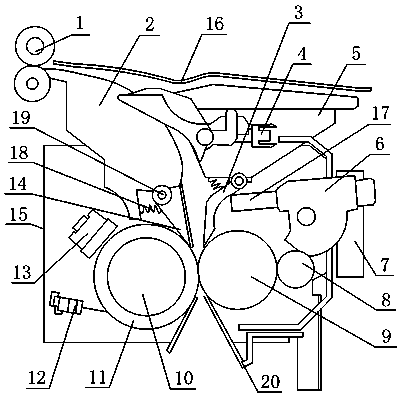

[0012] Such as figure 1 As shown, the fixing system capable of improving the accuracy of paper separation includes a hollow housing 15, an induction heating tube 10 is arranged in the housing 15, and a heating roller 11 is sleeved on the outer wall of the induction heating tube 10, and the heating roller 11 The center line coincides with the center line of the induction heating tube 10, the induction heating tube 10 is connected with a thermistor 12, the heating roller 11 is provided with a pressing roller 9 and a thermostat 13, and there is a gap between the pressing roller 9 and the heating roller 11, The thermostat 13 is close to the heating roller 11. Two feed guide plates 20 are arranged below the housing 15. The two feed guide plates 20 are arranged symmetrically along the vertical line. The tops of the feed guide plates 20 are arranged in the housing 15 and both face The gap between the pressure roller 9 and the heating roller 11, the top of the shell 15 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com