Non-axisymmetric lens group structure for lithography projection objective lens thermal effect correction

A non-axisymmetric, lithographic projection technology, used in microlithography exposure equipment, optics, photography, etc., can solve the problems of image quality deterioration, affecting imaging image quality, complex structure, etc., to reduce thermal resistance, reduce Air gap, good compensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

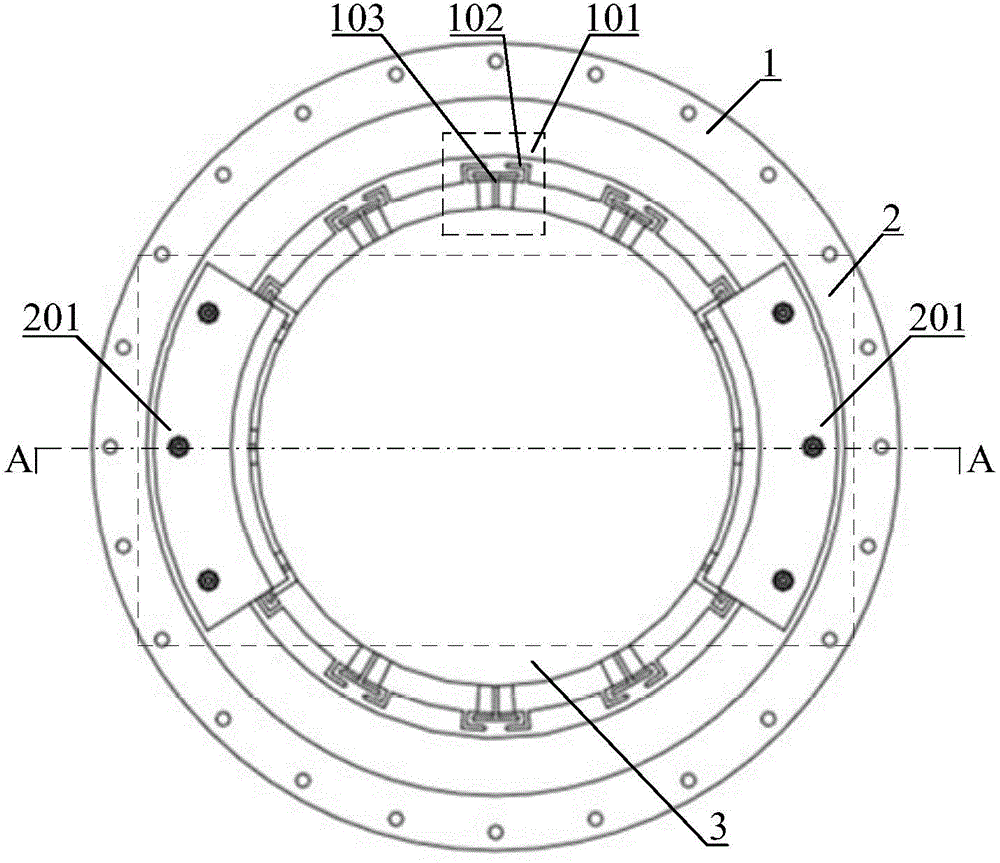

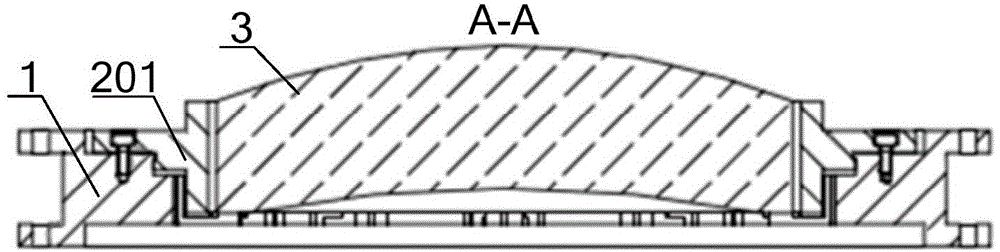

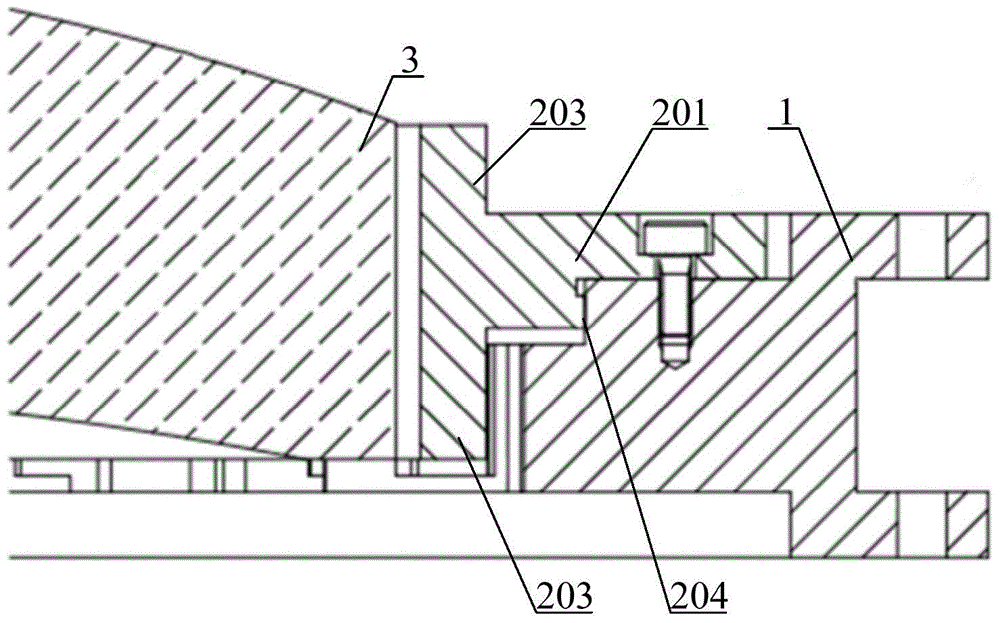

[0025] See attached figure 1 , attached figure 2 And attached image 3 , a non-axisymmetric lens group structure for correction of thermal effect of lithography projection objective lens according to the present invention comprises a mirror frame 1, a non-axisymmetric structure 2 and a lens 3;

[0026] The non-axisymmetric structure 2 includes two identical fan-shaped areas 201, and the two fan-shaped areas 201 are respectively symmetrical about up and down, left and right; the opening angle of the fan-shaped areas 201 of the non-axisymmetric structure 2 to the center can be adjusted to achieve different the compensation effect;

[0027] Multiple sets of flexible support units 101 are evenly distributed on the upper circumference of the picture frame 1; the lens 3 is fixedly connected to multiple sets of flexible support units 101 on the picture fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com