Oil level monitoring method of oil-immersed high-voltage electrical equipment

A high-voltage electrical equipment, oil-immersed technology, applied in the direction of displaying liquid level indicators through pressure measurement, can solve the problems affecting the intelligence level of electrical equipment and substations, inability to monitor insulating oil level information online, and difficulty in signal power insulation. Solve problems such as eliminating defects, improving authenticity and accuracy, and avoiding electromagnetic interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

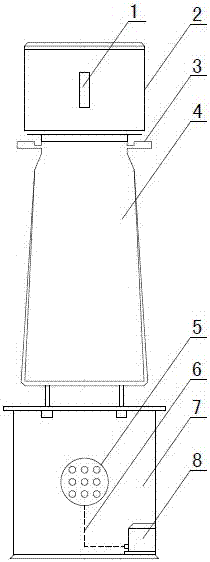

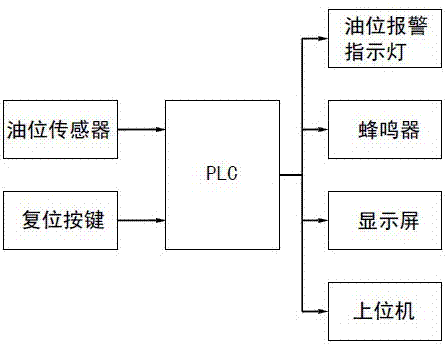

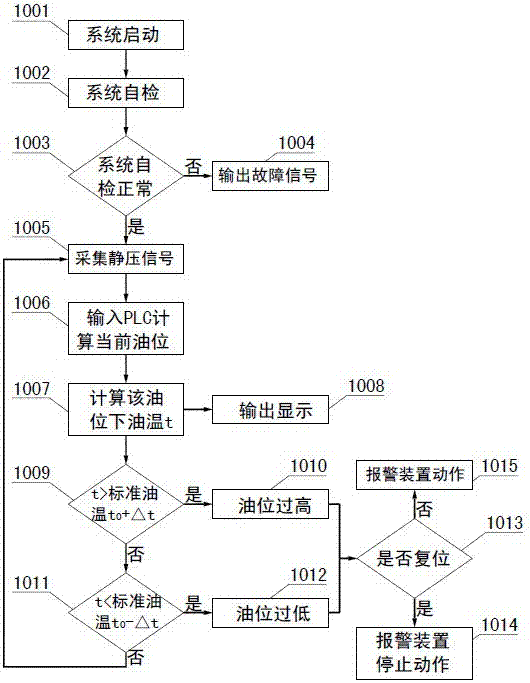

[0048] Figure 1~3 It is the best embodiment of the present invention, below in conjunction with the attached Figure 1~3 The present invention is described further:

[0049] In the oil-immersed high-voltage electrical equipment in the prior art, there are generally two upper and lower oil tanks connected to each other, and the insulating oil in the oil tanks plays the role of insulation, heat dissipation or arc extinguishing. A tube or pointer oil level gauge is generally installed at the top oil tank of oil-immersed high-voltage electrical equipment to monitor the oil level of the insulating oil inside the equipment. Electromagnetic components such as windings and iron cores of oil-immersed high-voltage electrical equipment are fixedly installed in the top oil tank or the bottom oil tank.

[0050] In the prior art, according to the characteristics of oil-immersed electrical equipment with a certain structure and height, the size of the top oil tank is determined by the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com