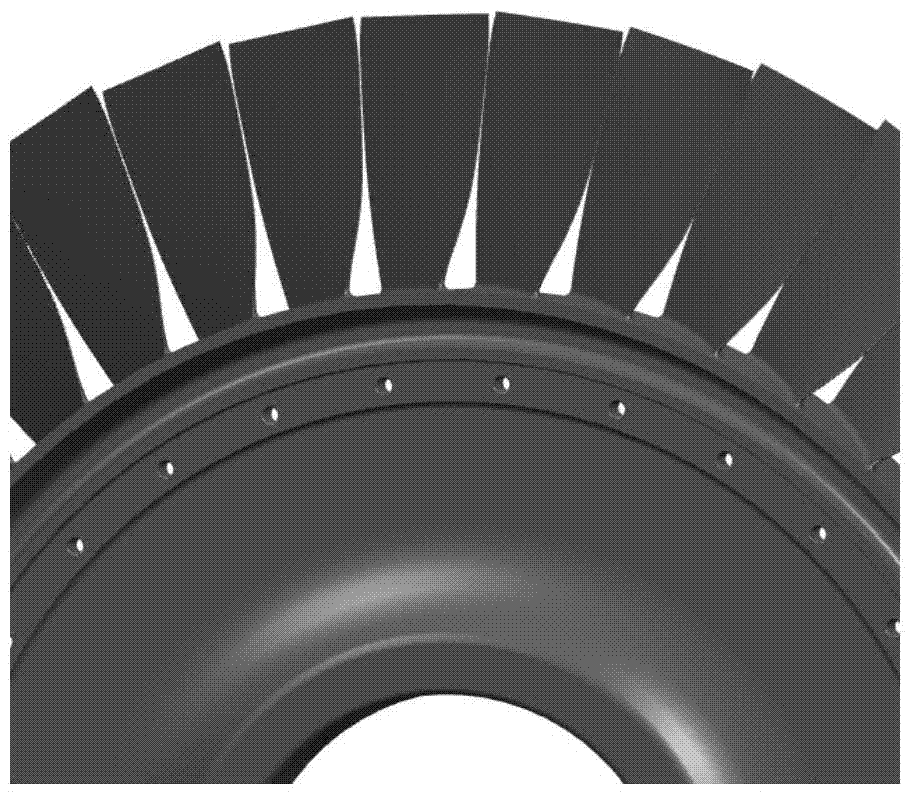

A Longitudinal Measurement Method for Complex Curved Surface Blades of Integral Blisks

A technology of complex curved surface and integral blisk, applied in measurement devices, instruments, optical devices, etc., can solve the problems of low measurement efficiency, inability to ensure the coincidence of measurement data points, and distortion of measurement results, and improve measurement efficiency and measurement path. Simple planning and improved detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

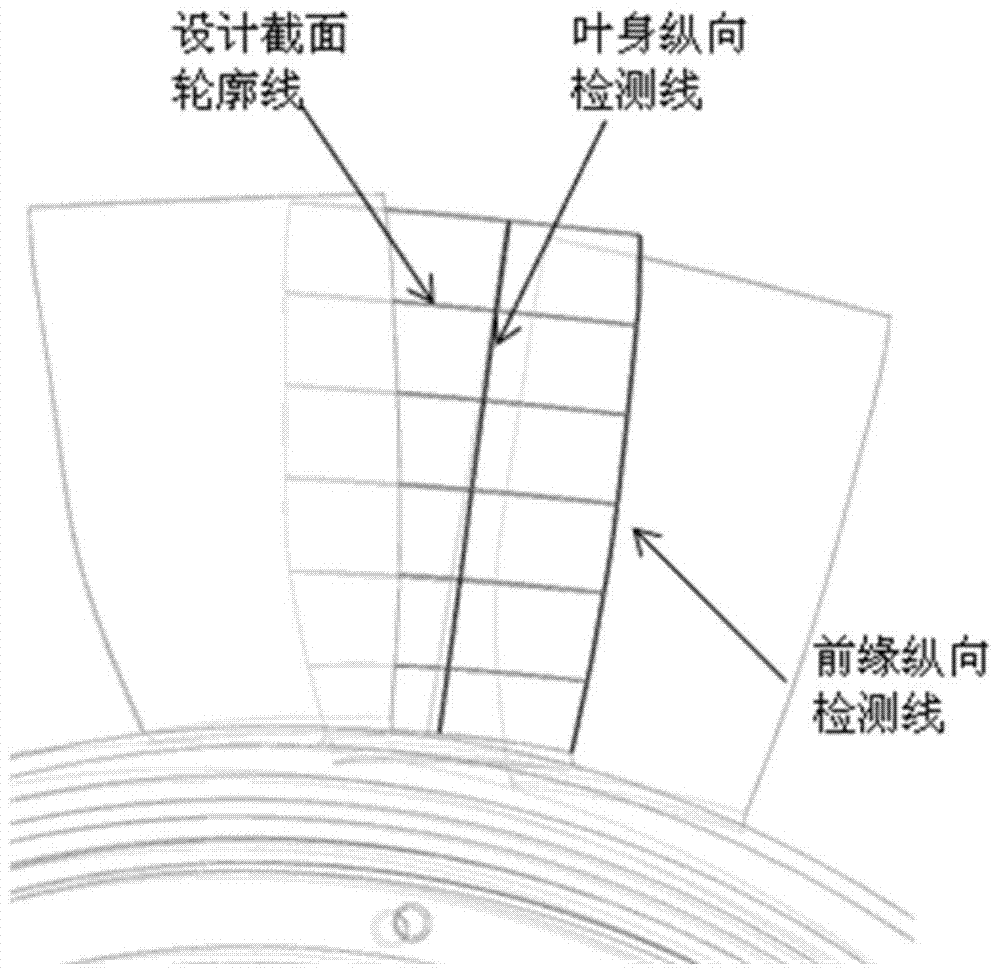

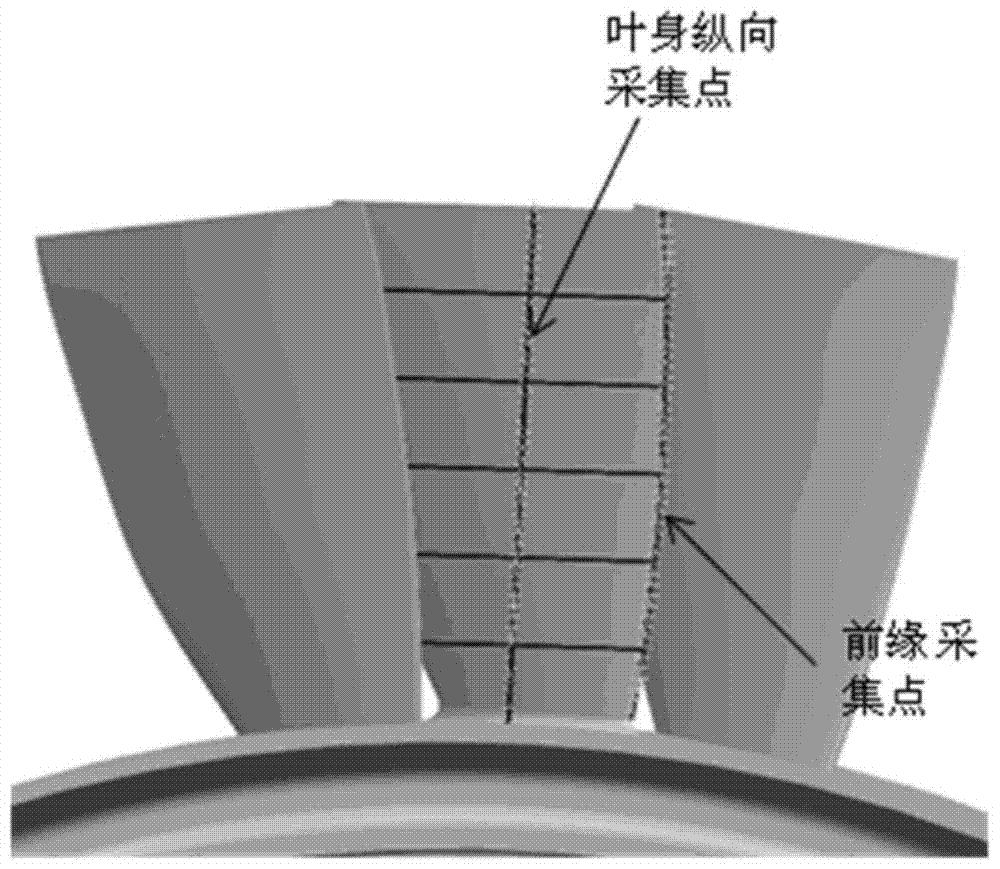

[0029] This embodiment provides a method for longitudinal measurement of blades with complex curved surfaces of integral blisks, which is characterized in that: the method for longitudinal measurement of blades with complex curved surfaces of integrated blisks first constructs a CAD three-dimensional model of complex curved surfaces according to the profile data of the theoretical section of the blade type ; Then extract longitudinal detection lines on the front edge, trailing edge, leaf pot, and leaf back of the blade respectively, use a three-coordinate measuring machine to detect the real blade according to the longitudinal detection method, and further perform data processing on the sampling points; finally, the processed The sampled data is imported into the CAD 3D model for comparison, and a comprehensive and real airfoil profile data set is obtained after analysis.

[0030] Specific steps are as follows:

[0031] Step 1: Use UGCAD 3D modeling software to carry out 3D so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com