A construction method for continuous construction using a shield machine and its supporting station

A construction method and shield machine technology, which can be applied to stations, earthwork drilling, railway car body parts, etc., can solve problems such as difficulty in improving construction progress, great impact on station safety, and poor waterproof performance, so as to solve groundwater problems and reduce The effect of abnormal process and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

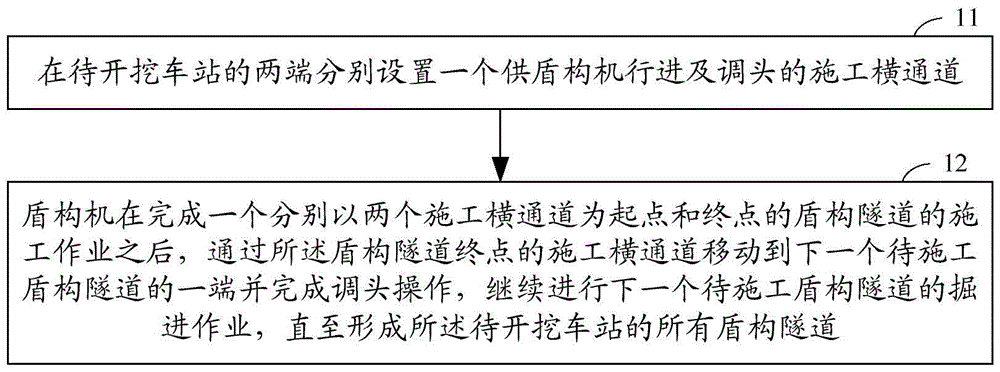

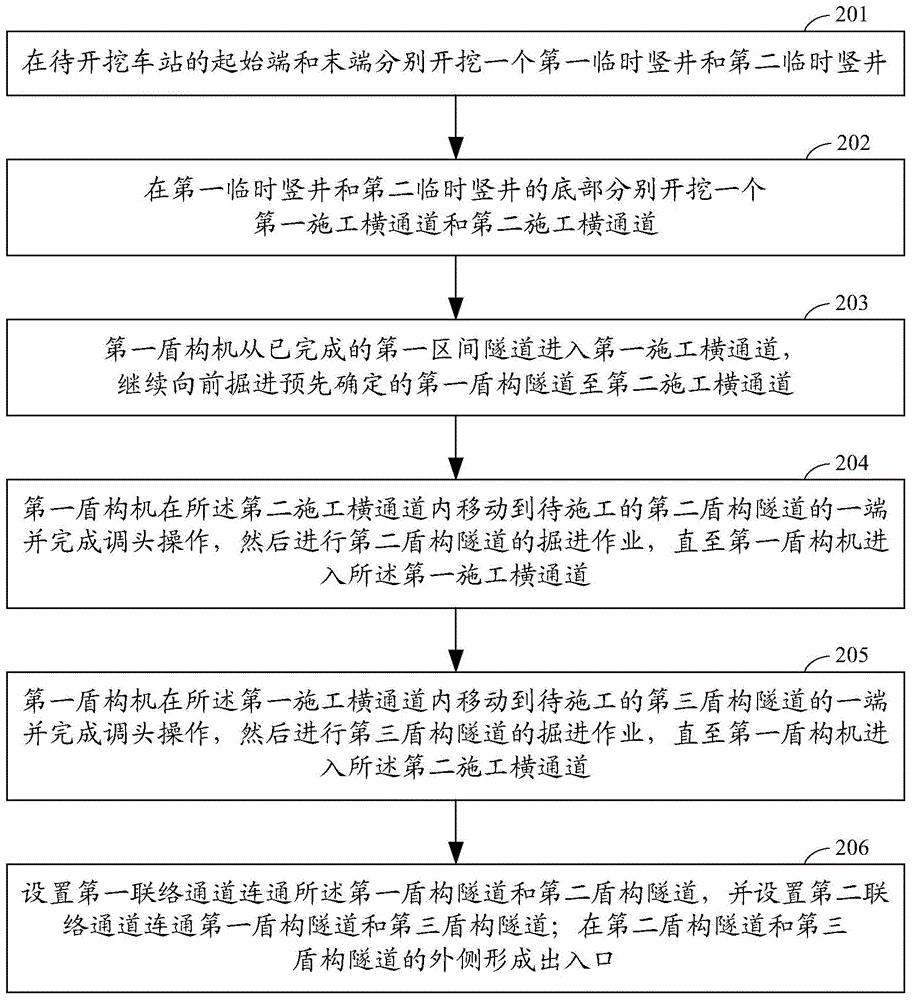

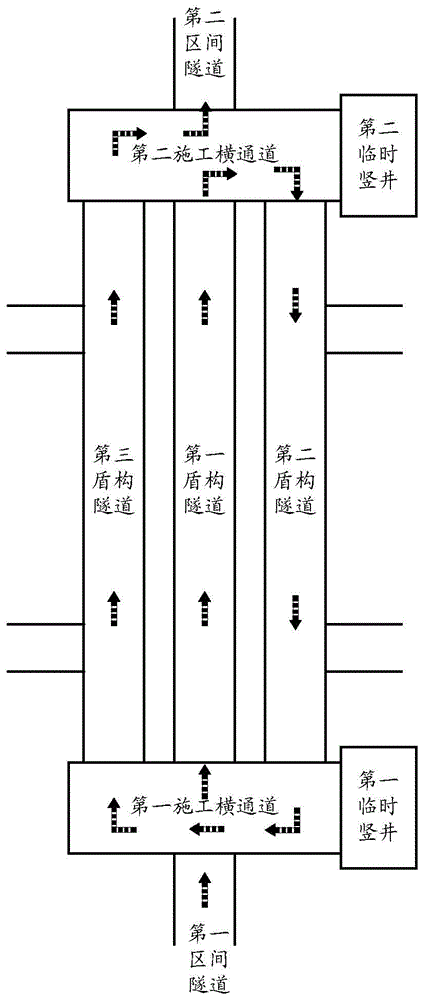

[0102] Embodiment 1: The construction method of large shield tunneling.

[0103] figure 2 It is a schematic flowchart of a construction method using a shield machine for continuous construction in Embodiment 1 of the present invention. image 3 It is a simple schematic diagram of a construction method using a shield machine for continuous construction in Embodiment 1 of the present invention. In the first embodiment, a large shield machine (that is, a large shield machine) is used, so that it can be formed as Figure 4 Station type shown. Such as figure 2 As shown, the construction method of using a shield machine for continuous construction in Embodiment 1 of the present invention may include the steps as follows:

[0104] Step 201, excavating a first temporary shaft and a second temporary shaft at the beginning and end of the station to be excavated respectively.

[0105] Step 202, excavating a first construction cross passage and a second construction cross passage r...

Embodiment 2

[0120] Embodiment 2: The construction method of small shield tunneling.

[0121] Figure 5 It is a schematic flowchart of a construction method using a shield machine for continuous construction in Embodiment 2 of the present invention. Figure 6 It is a simple schematic diagram of a construction method using a shield machine for continuous construction in Embodiment 2 of the present invention. Such as Figure 5 As shown, the construction method using the shield machine for continuous construction in Embodiment 2 of the present invention may include the steps as follows:

[0122] Step 501, respectively excavating a first temporary shaft and a second temporary shaft at the beginning and end of the station to be excavated.

[0123] Step 502, excavating a first construction cross passage and a second construction cross passage respectively at the bottom of the first temporary shaft and the second temporary shaft.

[0124] Wherein, since a small shield machine will be used in ...

Embodiment 3

[0142] Embodiment 3: Another construction method of small shield rotary excavation.

[0143] Figure 8 It is a schematic flowchart of a construction method using a shield machine for continuous construction in Embodiment 3 of the present invention. Figure 9 It is a simple schematic diagram of a construction method using a shield machine for continuous construction in Embodiment 3 of the present invention. Such as Figure 8 As shown, the construction method using a shield machine for continuous construction in Embodiment 3 of the present invention may include the following steps:

[0144] Step 801, excavating a first temporary shaft and a second temporary shaft at the beginning and end of the station to be excavated respectively.

[0145] Step 802, excavating a first construction cross passage and a second construction cross passage respectively at the bottom of the first temporary shaft and the second temporary shaft.

[0146] Wherein, since a small shield machine will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com