Beating-up mechanism with function of controlling post-forming thickness of double-layer fabric

A technology of double-layer fabric and lower layer, which is applied in looms, textiles, textiles and papermaking, etc., and can solve the problem of uneven quality of the upper and lower base fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

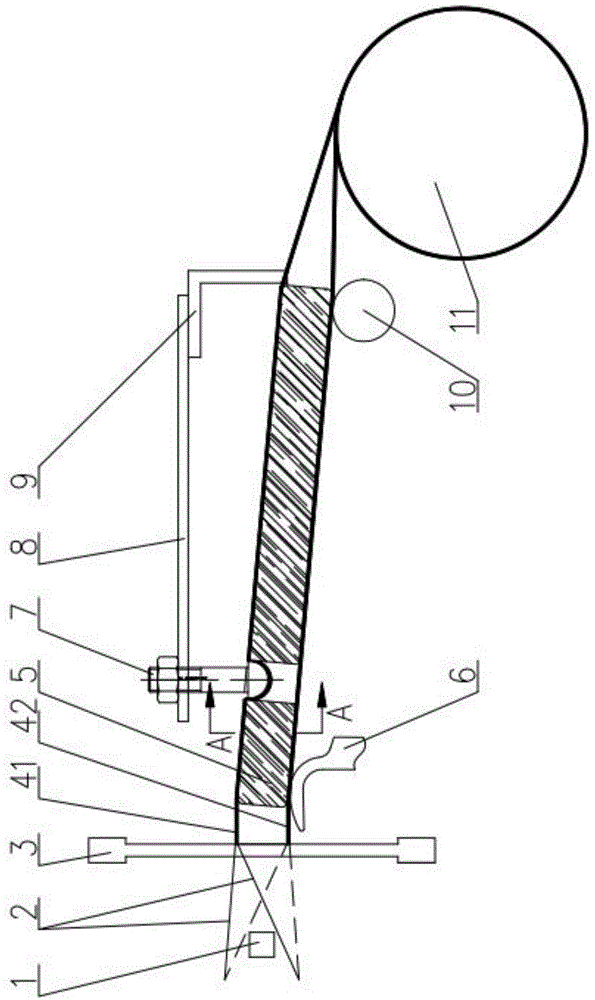

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] In the figure, there is a beating-up mechanism for controlling the thickness of the double-layer fabric after forming, including a rapier 1 and a reed 3, and the reed 3 is installed on a power mechanism that can provide swing power, such as a rocker mechanism, and the rapier 1 drives The weft thread, the reed 3 pushes two weft threads into the warp thread 2 (ie, the upper layer warp thread and the lower layer warp thread) at the beating station, and the warp thread 2 is beaten at the reed 3 to obtain a double-layer fabric, the upper layer base fabric and the lower layer The position where the base fabric is formed is the fell position.

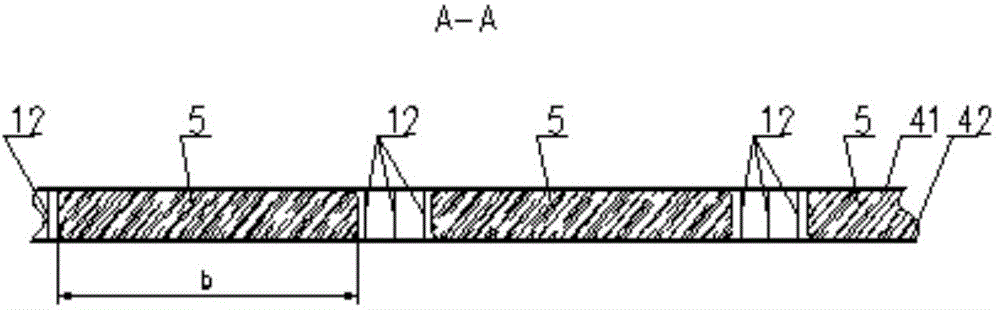

[0019] Several height-fixing boards 5 are arranged between the weaving fell position and the take-up roller. The height-fixing board is generally a plate-like structure with symmetrical upper and lower planes (surfaces). The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com