Purification device of PCB (printed circuit board) etching liquid medicine

A printed circuit board and etching solution technology, applied in the field of printed circuit boards, can solve problems such as copper surface discoloration, unfavorable product yield, solution decomposition, etc., to achieve the effects of reducing oil pollution, improving yield, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below with reference to the drawings.

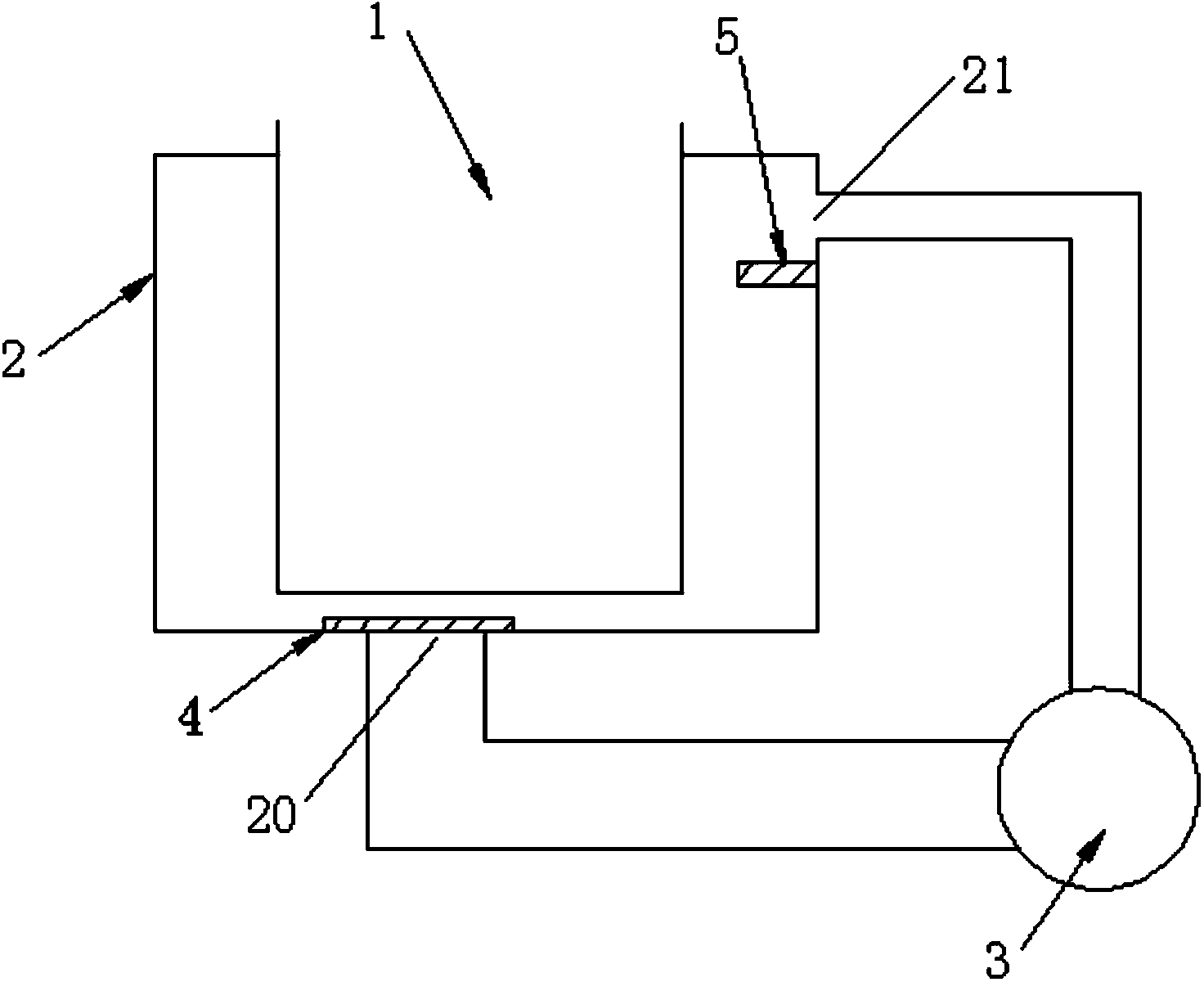

[0018] A purification device for printed circuit board etching solution according to the present invention, comprising an etching tank 1, a solution tank 2 for containing OSP antioxidants, and a nozzle assembly, and the solution tank 2 is positioned in the etching tank 1 , and the liquid medicine tank 2 communicates with the etching tank 1 through the nozzle assembly; the liquid medicine tank 2 is positioned with a backflow liquid outlet 20 and a backflow liquid inlet 21, and the backflow liquid outlet and the backflow liquid The inlet is connected through a circulation pipeline, and a circulation pump device 3 is also arranged on the circulation pipeline; in addition, a filter residue net 4 is positioned at the reflux liquid outlet 20, and is also positioned at the reflux liquid inlet 21. A purification element 5 for breaking bubbles and absorbing oil stai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com